Cathodic electrophoresis resin diamond wire saw preparation and ultra-high pressure treatment method

A diamond wire saw and cathodic electrophoresis technology, applied in electrolytic coatings, coatings, etc., can solve the problems of difficult control of the surface roughness and surface shape accuracy of the processed crystal, high consumption of abrasive mortar, and low wire speed of the wire saw. Improve photoelectric conversion efficiency, high manufacturing efficiency, and resource saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

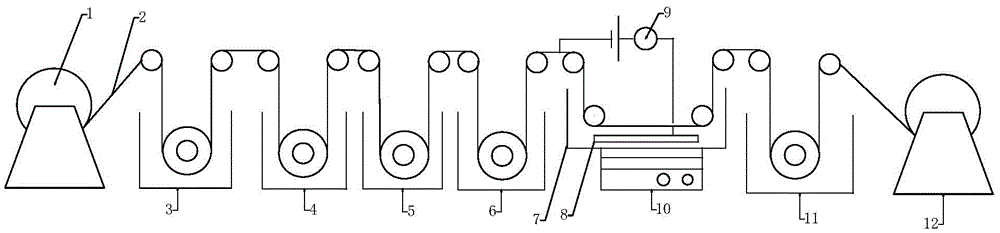

[0051] In the present invention, the preparation method of cathodic electrophoresis resin diamond wire saw and its ultra-high pressure treatment method comprises the following steps:

[0052] Step 1. Preparation of cathodic electrophoresis resin emulsion with diamond suspended, i.e. electrophoretic fluid:

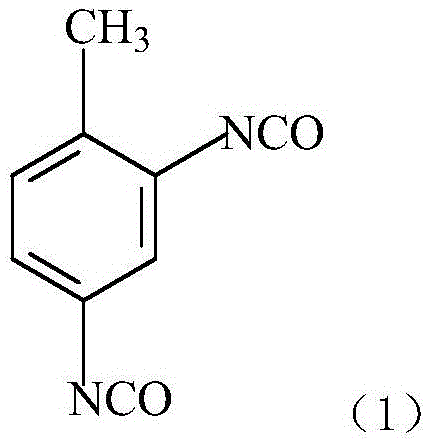

[0053] 1. Preparation of curing agent: In a three-necked flask equipped with 40g of TDI, add 1g of catalyst dibutyltin dilaurate, 30g of solvent ethylene glycol monobutyl ether and 22g of blocking agent methyl ethyl ketoxime, wherein the catalyst contains 10% Ethylene glycol monobutyl ether solution of dibutyltin dilaurate; then control the temperature at 40°C for 0.5h, 50°C for 2h, and 80°C for 4h;

[0054] 2. Prepare the main resin:

[0055] First, add 70g of epoxy resin and 20.9g of ethylene glycol monobutyl ether into the three-necked flask, raise the temperature to 80°C, keep stirring for 0.5h until the epoxy resin is completely dissolved;

[0056] Next, carry out ri...

Embodiment 2

[0071] The difference from Example 1 is that in step one, a certain amount of deionized water is used to dilute to a solid content of 19%; in step four, the ultra-high pressure treatment pressure is 700Mpa, and the treatment time is 3 minutes;

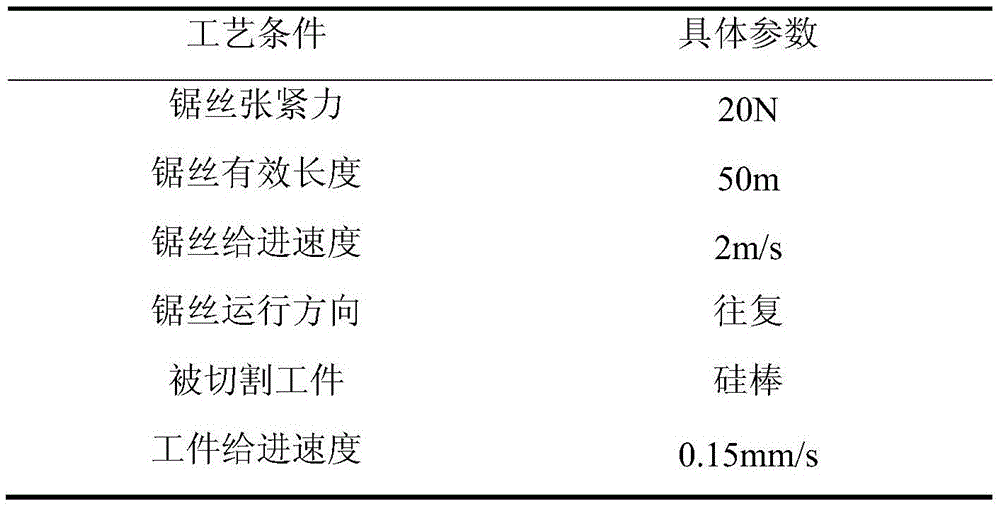

[0072] The diamond wire saw prepared in this example has a uniform diameter from the appearance. Randomly intercept a section of diamond wire saw with good appearance. Take a detection point every 5cm, and take ten points in total. The measured wire saw The average value of the outer diameter is 0.204mm, and the thickness of the resin layer is 12μm. The resin layer is smooth, without scratches, and without balling; under the ultra-depth microscope, it is found that the diamond embedded in the resin layer is about 1 / 2 to 2 / 3 ;Diamond particle density distribution is moderate and uniform;

[0073] The cutting times of the diamond wire saw prepared in this embodiment and the diamond wire saw after deep curing in this embodiment, that is, ...

Embodiment 3

[0075] The difference from Example 1 is that in step one, a certain amount of deionized water is used to dilute to a solid content of 20%; in step four, the ultra-high pressure treatment pressure is 650Mpa,

[0076] The diamond wire saw prepared in this example has a uniform diameter from the appearance; randomly intercept a section of diamond wire saw with good appearance, take a detection point every 5cm, take ten in total, and measure the diameter of the wire saw The average value of the outer diameter is 0.206mm, and the thickness of the resin layer is 13μm. The resin layer is flat, without scratches, and without balling; however, it is found that the diamond embedded in the resin layer is about 2 / 3 under the ultra-depth-of-field microscope; the diamond particle density evenly distributed;

[0077] The cutting times of the diamond wire saw prepared in this embodiment and the diamond wire saw after deep curing in this embodiment, that is, the diamond wire saw without ultra-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com