A kind of preparation method of end-capped fluorine-containing water-based polyurethane finishing agent and application thereof

A water-based polyurethane and finishing agent technology, applied in fiber treatment, improved handle fibers, anti-coloring and pollution/anti-fouling fibers, etc., can solve problems such as poor hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

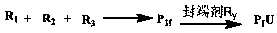

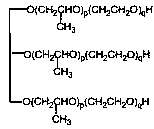

Method used

Image

Examples

Embodiment 1

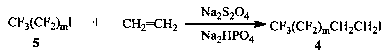

[0062] Perfluorooctane iodide (520g, 1.16mmol), Na 2 S 2 o 4 (20.9g, 0.12mol), Na 2 HPO 4 (21.5g), acetonitrile (900mL) and water (300mL) were added into a 2L autoclave, and ethylene gas was introduced to make the pressure reach 40atm. After continuing the reaction at 40-45°C for 3 hours, a significant drop in ethylene pressure was found. 19 F NMR traced the reaction and found that the raw materials had reacted completely, stopped the reaction, discharged excess ethylene gas, separated the lower organic layer, washed with water, washed with saturated saline, dried over anhydrous sodium sulfate, and removed the organic solvent under vacuum to obtain the compound perfluorooctane Ethyl iodide was a white solid (525 g, 95% yield, mp 56-57°C). 1 H NMR (300MHz, CDCl 3 )δ: 2.3-3.1 (m, 2H), 3.1-3.5 (m, 2H).

[0063] 19 F NMR (282MHz, CDCl 3 ): -81.38(t, J=9.9Hz, 3F), -113.73--113.66(m, 2F), -121.96--121.91(m, 6F), -122.26(s, 2F), -123.15(s, 2F), -126.63 (s, 2F).

[0064] Ad...

Embodiment 2

[0082] Perfluorohexane iodide (446g, 1mol), Na 2 S 2 o 4 (20.9g, 0.12mol), Na 2 HPO 4 (21.5g), acetonitrile (900mL) and water (300mL) were added into a 2L autoclave, and ethylene gas was introduced to make the pressure reach 40atm. The reaction was continued for 3 hours at 40-45°C. 19 F NMR traced the reaction and found that the raw materials had reacted completely, stopped the reaction, discharged excess ethylene gas, separated the lower organic layer, washed with water, washed with saturated saline, dried over anhydrous sodium sulfate, and removed the organic solvent under vacuum to obtain a white solid compound perfluoro Hexaneethyl iodide (331 g, 90% yield, mp 52-53°C).

[0083] Add KOH (14.0g, 0.2mol) and 40mL of methanol into a 250mL three-neck flask equipped with a reflux condenser, dropping funnel and thermometer, stir magnetically at room temperature, and mix the compound perfluorohexane ethyl iodide (74.0g, 0.2 mol) was dissolved in 100 mL of Freon-113 solvent,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com