Crucible for preparing polycrystalline silicon ingot and growth method of polycrystalline silicon ingot

A technology for polycrystalline silicon ingots and crucibles, which is applied in the directions of polycrystalline material growth, single crystal growth, crystal growth, etc. It can solve the problems of poor repeating effect, increased cost of casting ingots, and complicated crucible structure, so as to increase the size and improve the utilization rate , Improve the effect of electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

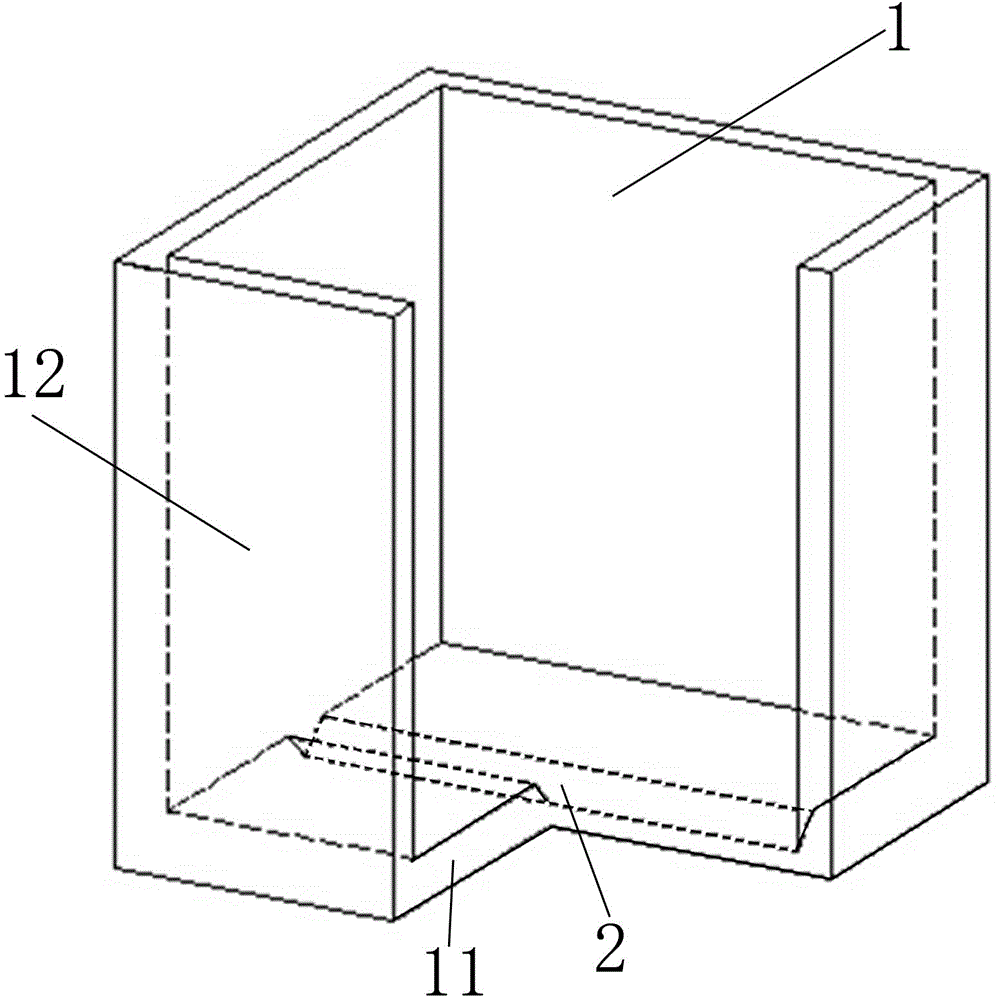

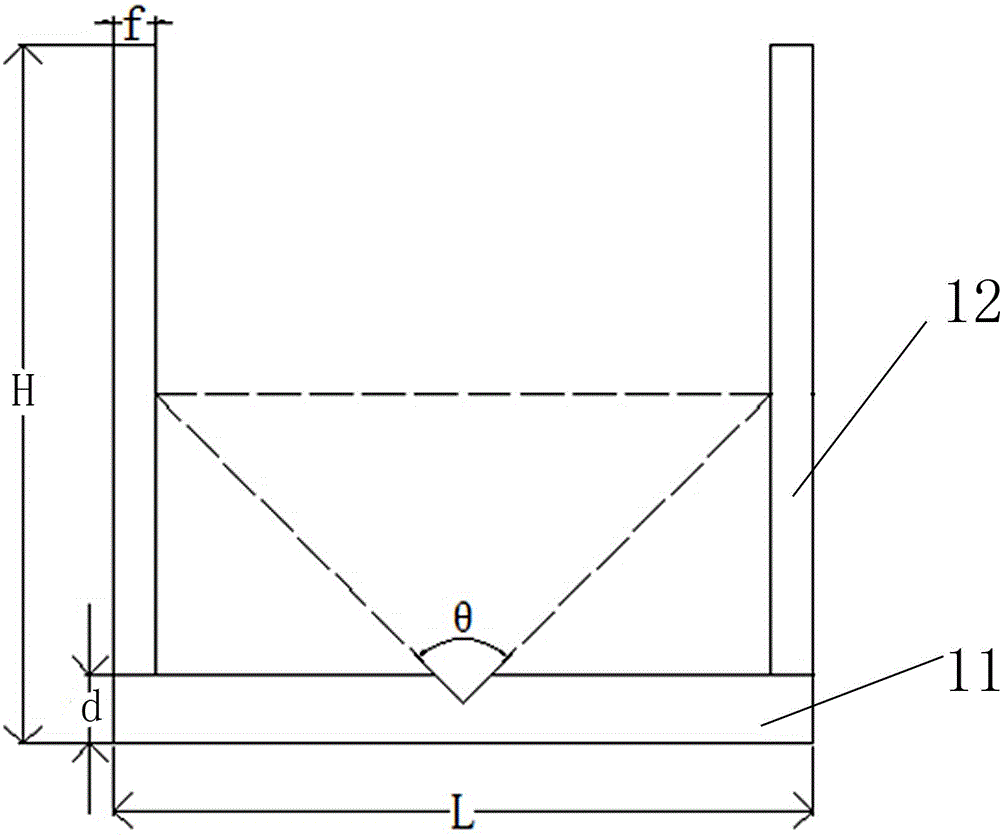

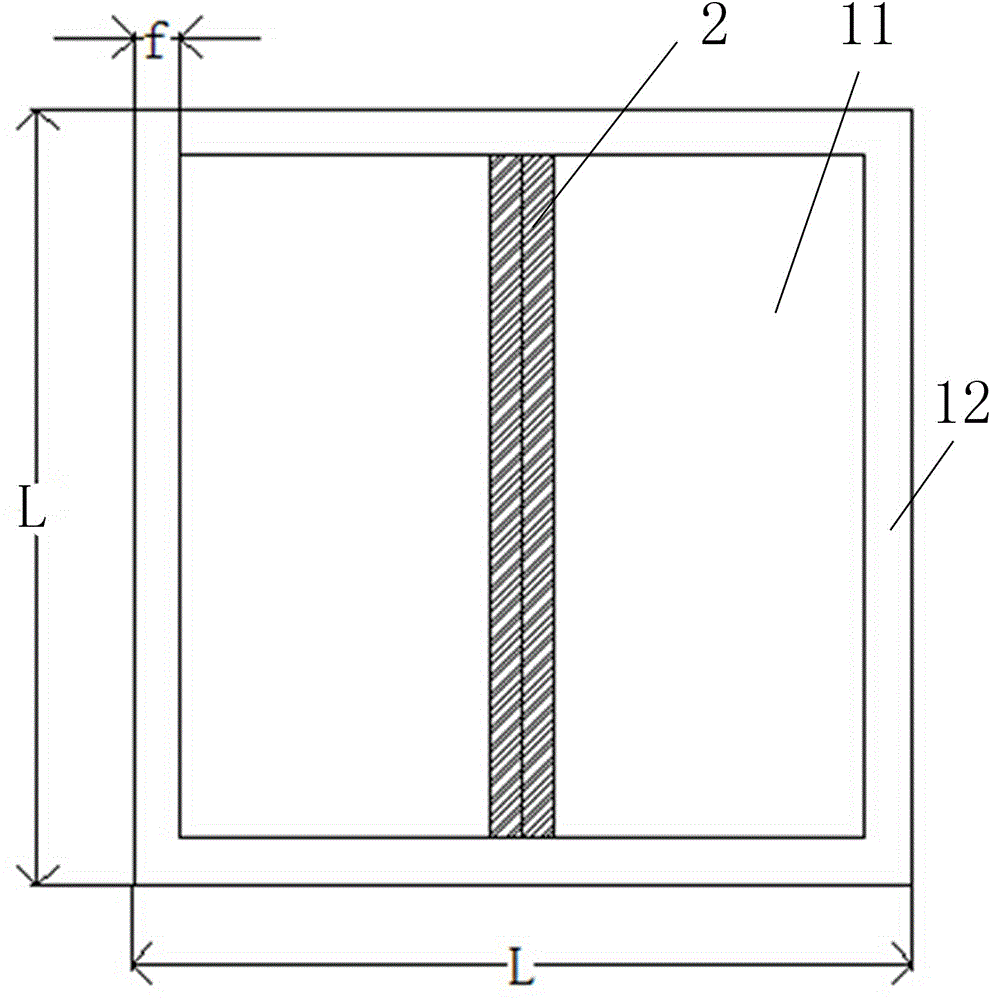

[0030] There is a crucible 1 with a "V"-shaped long groove 2 on the bottom surface, and the cross-sectional view of its structure is as follows figure 2 As shown, the thickness f of the crucible wall 12 is 12 mm, the thickness d of the bottom surface 11 is 20 mm, the side length L of the bottom surface 11 is 198 mm, and the height H of the crucible wall 12 is 200 mm; The center line of the bottom surface 11 is parallel to one side of the square bottom surface 11; the depth h of the "V"-shaped long groove 2 is 8 mm, and the angle θ between the two hypotenuses of the "V"-shaped long groove is 90 degrees. The inner wall of crucible 1 is sprayed with silicon nitride, and heat-treated at 1050 °C for 5 hours to form a dense silicon nitride coating; 6 kg of P-type polysilicon raw material with a purity of 6N is placed in crucible 1 according to a certain method; The furnace body is evacuated to a vacuum of 10 Pa and starts to heat; use argon as a protective gas; heat to 1540 °C unde...

Embodiment 2

[0033] A crucible 1 with two "V"-shaped long grooves 2 is opened on the bottom surface, and the cross-sectional view of its structure is as follows Figure 5 As shown, the thickness f of the crucible wall 12 is 12 mm, the thickness d of the bottom surface 11 is 20 mm, the side length L of the bottom surface 11 is 198 mm, and the height H of the crucible wall 12 is 200 mm. The center of the bottom surface 11 is parallel to the line of symmetry on one side and is distributed symmetrically. The intersection of the extension lines on both sides of the two "V"-shaped long grooves 2 and the crucible wall 12 and the extension line of the adjacent sides of the two "V"-shaped long grooves 2 The intersection points are at the same height, the vertical distance h2 from the intersection point to the inner bottom of the crucible is 36 mm, the depth h of the "V"-shaped long groove 2 is 8 mm, and the angle θ between the two hypotenuses of the "V"-shaped long groove 2 is 90 degrees. The proce...

Embodiment 3

[0035] A crucible 1 with three "V"-shaped long grooves 2 is opened on the bottom surface, and the cross-sectional view of its structure is as follows Figure 6 As shown, the thickness f of the crucible wall 12 is 12 mm, the thickness d of the bottom surface 11 is 20 mm, the side length L of the bottom surface 11 is 198 mm, the height H of the crucible wall 12 is 200 mm, and a "V" shaped long groove 2 is located on the bottom surface of the crucible 1 In the middle of 11, the intersection of the extension line of the other two "V"-shaped long grooves 2 adjacent to the crucible wall 12 and the crucible wall 12 and the extension line of the other side of the two "V"-shaped long grooves 2 and the middle "V" The intersection of the extension lines of the adjacent sides of the "shaped long groove 2 is at the same height, the vertical distance h3 between the intersection point and the inner bottom of the crucible 1 is 21.3 mm, the depth h of the "V" shaped long groove 2 is 8 mm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com