Sample pretreatment method for measuring heteroatom content of polymer and application thereof

A technology of sample pretreatment and determination method, which is applied in the field of sample pretreatment for determining the content of heteroatoms in polymers. It can solve the problems of long digestion period, narrow application range, and low recovery rate, and achieve fast digestion speed and wide application range. , Guarantee the effect of recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

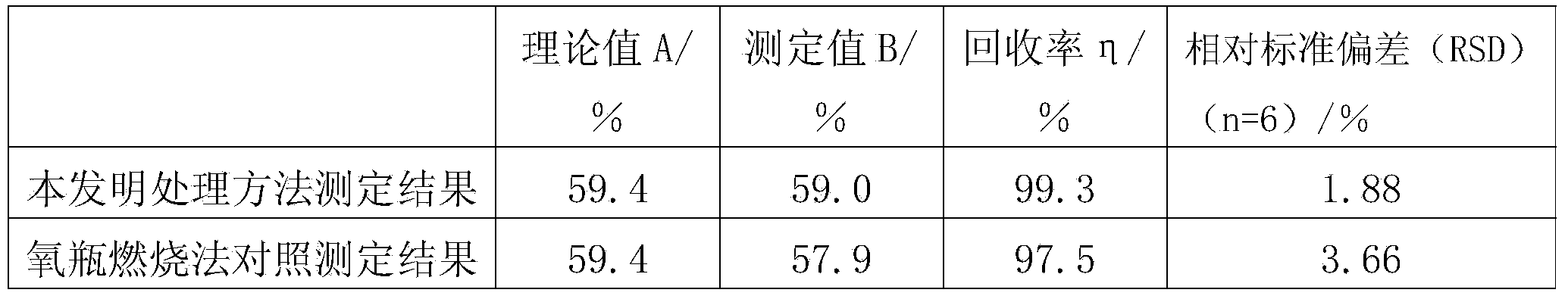

[0026] Embodiment 1, the pretreatment of polyvinylidene fluoride (PVDF) sample and the determination of fluorine atom content

[0027] 1. Pretreatment of polyvinylidene fluoride samples

[0028] Taking pure polyvinylidene fluoride (PVDF) as a sample, sample pretreatment is carried out, and the resulting solution can be used for the determination of fluorine content therein. The sample pretreatment method includes the following steps:

[0029] 1) Preparation of polymer samples

[0030] For powdered solid polymers, no pretreatment is required, and the sample can be directly weighed and digested;

[0031] For film-like or flake-like solid polymers, cut them into pieces no larger than 2mm (length)×2mm (width);

[0032] For blocky solid polymers, scrape the surface with a blade to obtain debris for testing, or cut it into particles no larger than 1mm (length) × 1mm (width) × 0.5mm (height);

[0033] In this embodiment, a small sample of polyvinylidene fluoride is taken and cut i...

Embodiment 2

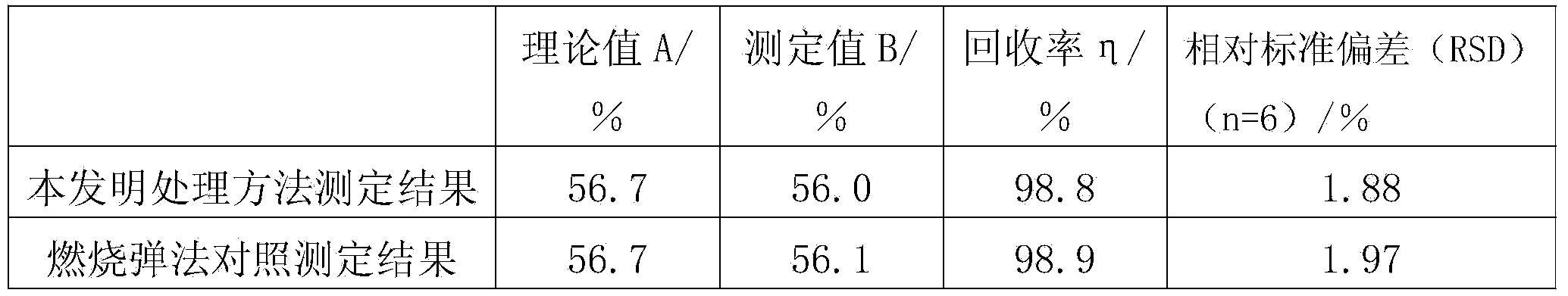

[0047] The pretreatment of embodiment 2, polyvinyl chloride (PVC) sample and chlorine atom content determination

[0048] 1. Pretreatment of PVC samples

[0049] With pure polyvinyl chloride (PVC) as sample, carry out sample pretreatment, the solution of processing gained can be used for carrying out wherein the mensuration of chlorine content, and sample pretreatment method comprises the following steps:

[0050] 1) Preparation of polymer samples

[0051] For powdered solid polymers, no pretreatment is required, and the sample can be directly weighed and digested;

[0052] For film-like or flake-like solid polymers, cut them into pieces no larger than 2mm (length)×2mm (width);

[0053] For blocky solid polymers, scrape the surface with a blade to obtain debris for testing, or cut it into particles no larger than 1mm (length) × 1mm (width) × 0.5mm (height);

[0054] In this embodiment, a polyvinyl chloride (PVC) powder sample is taken and weighed directly.

[0055] 2) Dige...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com