Aerospace tensile power cable

A power cable and tensile technology, which is used in the field of aerospace tensile power cables, can solve the problems of weather resistance, non-combustibility, chemical resistance and other properties that cannot be taken into account at the same time, poor aging resistance of cable jacket materials, and conductor center distance changes. and other problems, to achieve the effects of excellent aging resistance, excellent radiation resistance, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

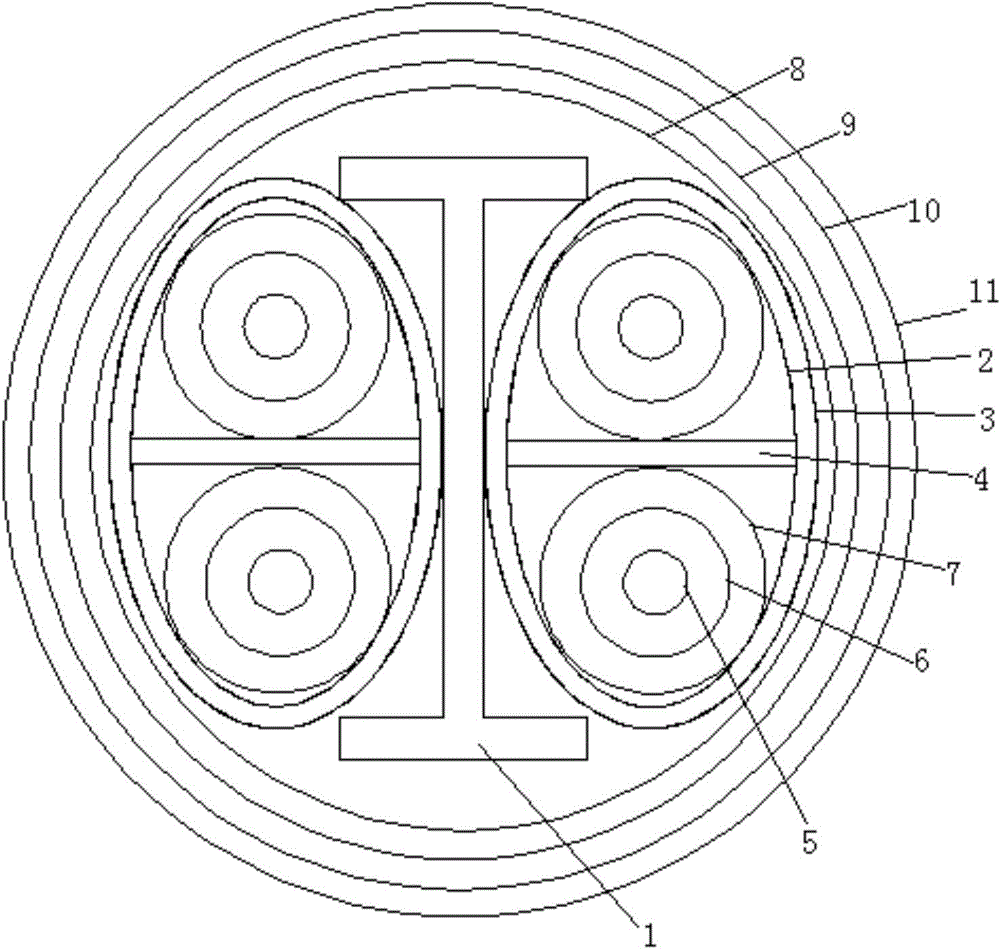

[0011] Such as figure 1 As shown, an aerospace tensile power cable includes a cable core, and the cable core includes an I-shaped nylon skeleton 1, and wire cores are respectively placed on the left and right sides of the I-shaped nylon skeleton 1. The wire core includes an oval nylon skeleton 2, coated with waterproof glue 3 on the outside of the oval nylon skeleton 2, and an elastic backing plate 4 is placed inside the oval nylon skeleton 2, and placed on both sides of the elastic backing There is a conductor 5, and the outer side of the conductor 5 is covered with an aluminum-magnesium alloy wire braided shielding layer 6 and a flame-retardant silicone inner sheath 7, and the outer side of the cable core is covered with a steel wire braided tensile cylinder in turn 8. Carbon fiber braided layer 9 , aluminum foil wrapping layer 10 and outer sheath 11 .

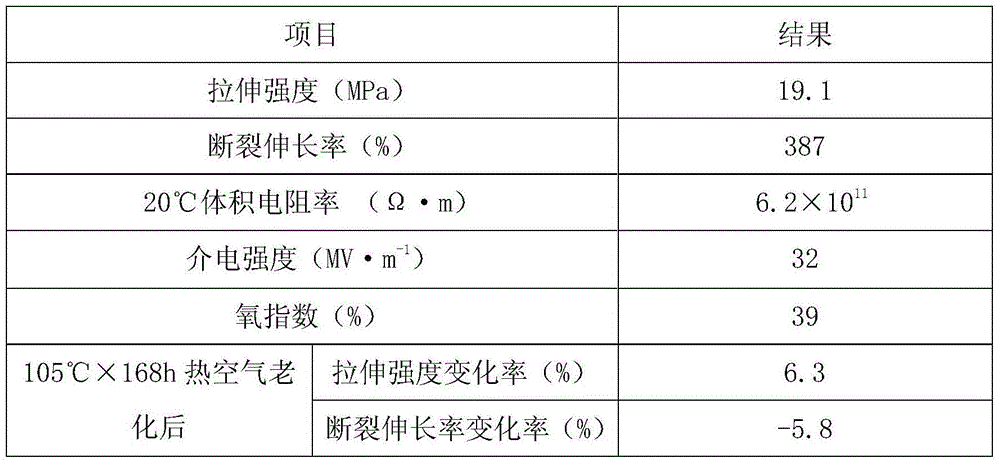

[0012] The material of the outer sheath 11 is made of the following raw materials in parts by weight: polyurethane rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com