Perovskite membrane and preparation and application method thereof

An application method and perovskite technology, which is applied in the field of solar cells, can solve problems such as uneven thickness and poor flatness of perovskite films, and achieve the effects of improving flatness, improving solvent resistance, and good experimental repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 (comparative example)

[0027] will be sputtered with fluorine-doped SnO 2 (FTO) transparent conductive glass was ultrasonically cleaned twice with detergent, tap water, deionized water, acetone, and isopropanol in sequence, blown dry with nitrogen, and immediately placed in an ultraviolet ozone surface treatment equipment (UVO) for 15 minutes at 2000rpm The PEDOT:PSS solution was spin-coated at a rotating speed of 100°C, and thermally annealed at a temperature of 150° C. in air for 15 minutes to obtain a hole transport layer with a thickness of about 30 nm. Then PbI 2 with CH 3 NH 3 I was dissolved in DMF (N,N-dimethylformamide) solution at a mass ratio of 1:1, heated for 12 hours to prepare a perovskite solution, and the perovskite solution with a concentration of 30wt% was spun down at a speed of 3000rpm Coated on the hole transport layer, followed by thermal annealing for 2 hours, the thickness of the obtained perovskite layer is 300nm. and then th...

Embodiment 2

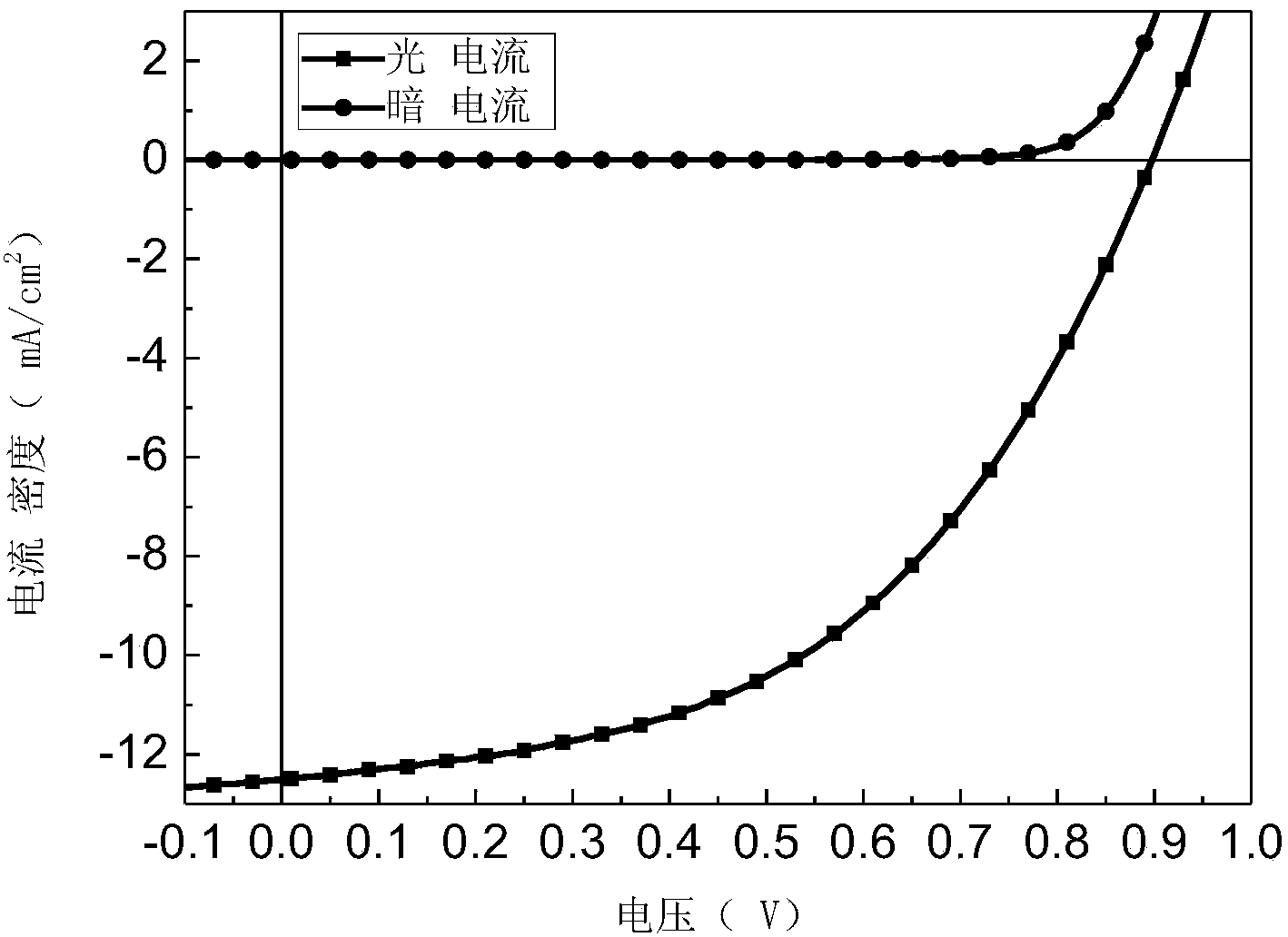

[0029] will be sputtered with fluorine-doped SnO 2 (FTO) transparent conductive glass was ultrasonically cleaned twice with detergent, tap water, deionized water, acetone, and isopropanol in sequence, blown dry with nitrogen, and immediately placed in an ultraviolet ozone surface treatment equipment (UVO) for 15 minutes at 2000rpm The PEDOT:PSS solution was spin-coated at a rotating speed of 100°C, and thermally annealed at a temperature of 150° C. in air for 15 minutes to obtain a hole transport layer with a thickness of about 30 nm. Then PbI 2 PbI at a concentration of 300 mg / mL 2 The precursor solution was directly spin-coated on the above-mentioned hole transport layer at a speed of 2000rpm, and then placed on the hot stage, and then every 1cm 2 The resulting PbI 2 The membrane uses about CH 3 NH 3 The dosage ratio of I20mg, the CH 3 NH 3 I powder is evenly sprinkled on the obtained PbI 2Around the film, cover it with a petri dish, keep it warm at 150°C for 2 hours...

Embodiment 3

[0031] will be sputtered with fluorine-doped SnO 2 (FTO) transparent conductive glass was ultrasonically cleaned twice with detergent, tap water, deionized water, acetone, and isopropanol in sequence, blown dry with nitrogen, and immediately placed in an ultraviolet ozone surface treatment equipment (UVO) for 15 minutes at 2000rpm The PEDOT:PSS solution was spin-coated at a rotating speed of 100°C, and thermally annealed at a temperature of 150° C. in air for 15 minutes to obtain a hole transport layer with a thickness of about 30 nm. Then PbI 2 PbI at a concentration of 300 mg / mL 2 The precursor solution was directly spin-coated on the above-mentioned hole transport layer at a speed of 2000rpm, and then placed on the hot stage, and then every 1cm 2 The resulting PbI 2 The membrane uses about CH 3 NH 3 The dosage ratio of I20mg, the CH 3 NH 3 I powder is evenly sprinkled on the obtained PbI 2 Around the membrane, cover it with a Petri dish, keep it warm at 150°C for 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com