Preserving method of low-salt sea bass

A processing method and technology for sea bass, which are applied in the field of salting and processing of low-salt sea bass, can solve the problems of poor taste, hard texture of fish and high salt content, and achieve soft and hard muscles without rehydration and salt reduction treatment. Moderate, nutrient-rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for salting and processing low-salt sea bass, comprising the following steps:

[0044] (1) Pretreatment: Remove the scales and viscera of the fresh fish, and rinse them with clean water.

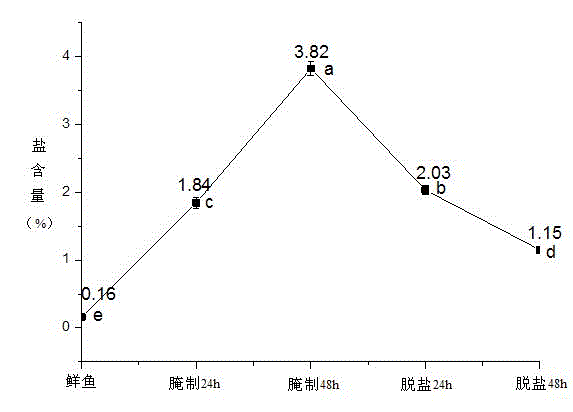

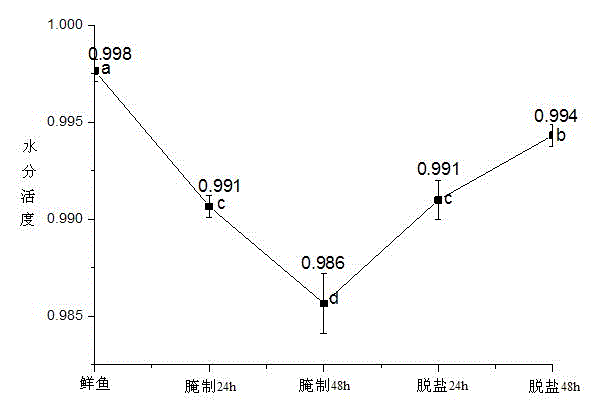

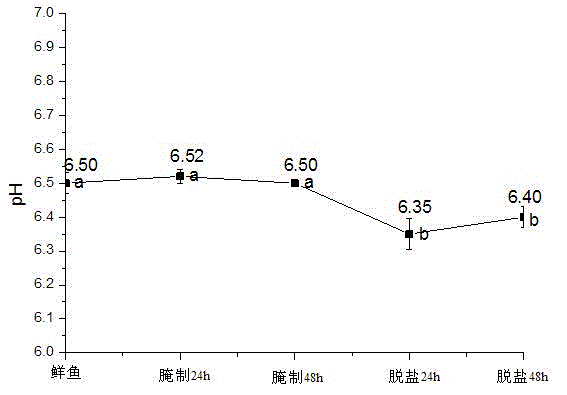

[0045] (2) Marinating: put fish weighing about 500g into 6L of concentrated brine with a mass concentration of 13%, and marinate at a temperature below 15°C for 50 hours. After marinating, take it out and drain.

[0046] (3) Desalination: quickly put the drained fish into the desalination solution and soak for 50 hours below 15°C.

[0047] The desalination solution is made by mixing the following components by weight percentage: 1% seaweed polyphenol, 0.1% vitamin C, 1% compound phosphate, and 97.9% water.

[0048] The composite phosphate is prepared by mixing the following components in parts by weight: 42 parts of sodium tripolyphosphate, 25 parts of sodium hexametaphosphate, 12 parts of sodium pyrophosphate, 18 parts of sodium dihydrogen phosphate, and 8 parts of disodium h...

Embodiment 2

[0056] A method for salting and processing low-salt sea bass, comprising the following steps:

[0057] (1) Pretreatment: Remove the scales and viscera of the thawed frozen fish, and rinse them with clean water.

[0058] (2) Marinating: put fish weighing about 500g into 6.5L concentrated brine with a mass concentration of 15%, and marinate at a temperature below 15°C for 45 hours. After marinating, take it out and drain.

[0059] (3) Desalting: quickly put the drained fish into the desalting solution and soak for 45 hours below 15°C.

[0060] The desalination solution is prepared by mixing the following components by weight percentage: 5% seaweed polyphenols, 2% vitamin C, 5% complex phosphate, and 88% water.

[0061] The composite phosphate is prepared by mixing the following components in parts by weight: 46 parts of sodium tripolyphosphate, 20 parts of sodium hexametaphosphate, 10 parts of sodium pyrophosphate, 15 parts of sodium dihydrogen phosphate, and 4 parts of disodiu...

Embodiment 3

[0069] A method for salting and processing low-salt sea bass, comprising the following steps:

[0070] (1) Pretreatment: Remove the scales and viscera of the fresh fish, and rinse them with clean water.

[0071] (2) Marinating: Put the fish weighing about 800g into 10L of concentrated brine with a mass concentration of 14%, and marinate for 48 hours below 15°C. After the marinating, take it out and drain.

[0072] (3) Desalting: quickly put the drained fish into the desalting solution and soak for 48 hours below 15°C.

[0073] The desalination solution is prepared by mixing the following components by weight percentage: 3% seaweed polyphenols, 1% vitamin C, 3% complex phosphate, and 93% water.

[0074] The composite phosphate is prepared by mixing the following components in parts by weight: 44 parts of sodium tripolyphosphate, 22 parts of sodium hexametaphosphate, 11 parts of sodium pyrophosphate, 16 parts of sodium dihydrogen phosphate, and 7 parts of disodium hydrogen phos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com