Temperature response type beta-cyclodextrin silica gel stationary phase and preparation method thereof

A temperature-responsive, cyclodextrin technology, applied in the field of liquid chromatography stationary phase preparation, can solve the problems of limited types of temperature-sensitive chromatographic packing materials, and achieve the effects of avoiding non-specific adsorption, flexible application, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

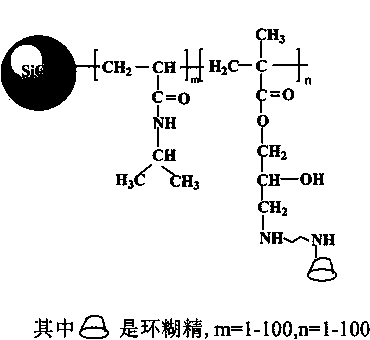

[0027] Preparation of β-cyclodextrin derivatives

[0028] Dissolve 20.0g of sodium hydroxide in 800mL of distilled water, add 40.0g of β-cyclodextrin, under vigorous stirring at 0-5°C, add 40.0g of p-toluenesulfonyl chloride to react for 5 hours; filter, cool the filtrate to 0°C, wash with hydrochloric acid Adjust the pH to 6-7 and store in the refrigerator overnight to obtain a white solid product; wash and dry to obtain benzoylated β-cyclodextrin. ;

[0029] Weigh 10.0g of benzoylated β-cyclodextrin, then add 60mL of ethylenediamine, stir and react in a 75°C water bath for 4 hours; then add dropwise to the above reaction solution into 500mL of cold acetone, and immediately form a white precipitate , filter under reduced pressure, redissolve the white precipitate in 60mL water / methanol (v / v=3:1) mixed solution, filter to obtain a light yellow clear liquid; slowly pour the light yellow clear filtrate into 200mL acetone, reduce pressure Collect the white precipitate by filtra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com