Nitrogen-doped fluorescent carbon-dot and carbon-dot graphene composite as well as production method and application thereof

A fluorescent carbon dot, nitrogen doping technology, applied in chemical instruments and methods, luminescent materials, chemical/physical processes, etc., can solve the problems of low calorific value, high nitrogen content, large pollution, etc., and achieve a large steady-state current , the effect of high catalytic activity and low start-up potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In a preferred embodiment of the present invention, regarding the preparation method of nitrogen-doped fluorescent carbon dots, the specific steps are as follows:

[0045] 1. Crush and grind the coal with high nitrogen content, and sieve it to below 200 mesh. The sieve used is a Taylor sieve. Dry it overnight in an oven at 110°C. Take an appropriate proportion of coal powder and coal tar binder, fully knead and stir Uniform, extruded into a rod shape with a diameter of 10mm under the condition of 1-5MPa, and carbonized for 2 hours at 500-1500°C in nitrogen or argon;

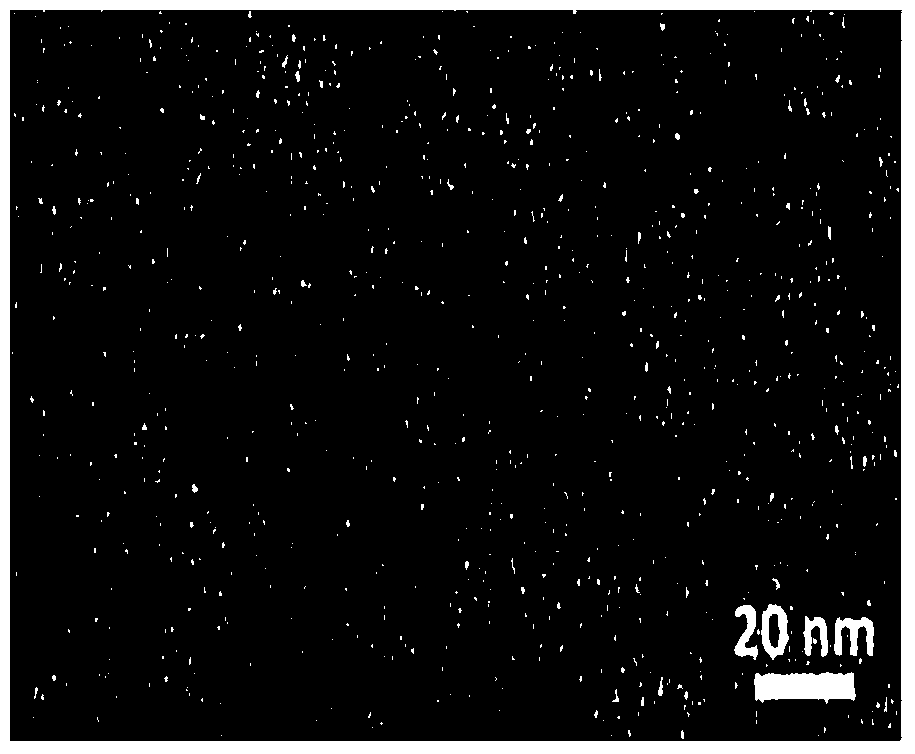

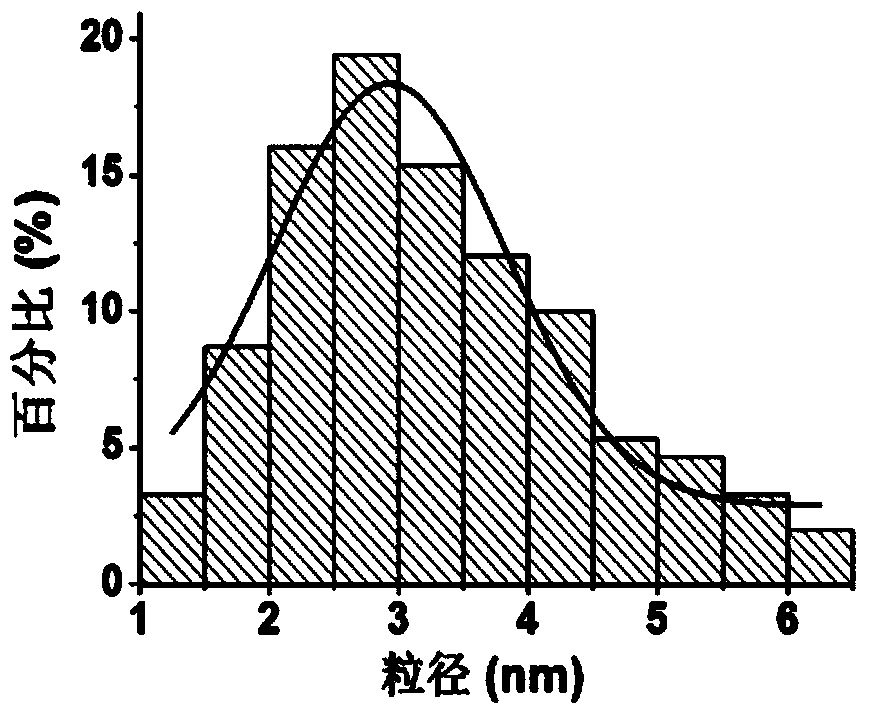

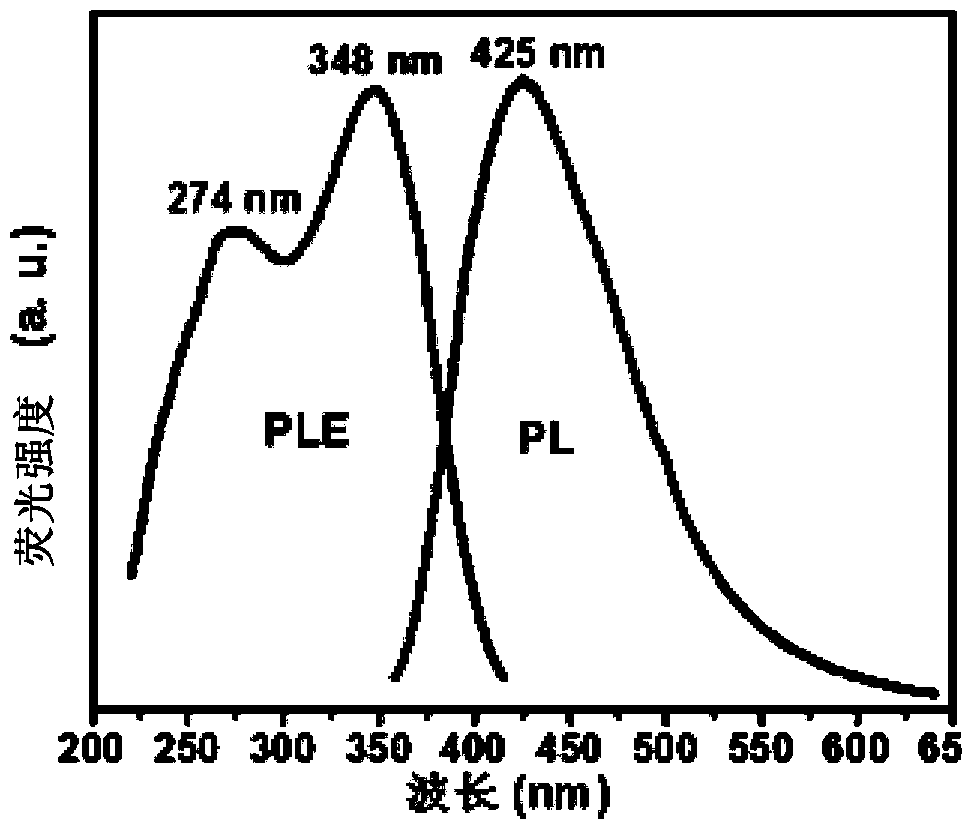

[0046] 2. Prepare 0.05-0.2mol / L NaOH solution as the electrolyte, then add 0.1-1mol / L ammonia water, use the above-mentioned coal-based carbon rod as the anode, the platinum sheet as the counter electrode, and the calomel electrode as the reference electrode. Under the bias condition of 2-15V, react for 2-6 hours, collect the electrolyte solution containing a large number of carbon dots, use a 3500Da dialy...

Embodiment 1

[0065] 1. Preparation of nitrogen-doped carbon dots: crush and grind anthracite with high nitrogen content, sieve it to below 200 mesh, dry it in an oven at 110°C overnight, take 100g of coal powder, 50g of coal tar, fully knead, and stir evenly. Extruded into rods with a diameter of 10mm under the condition of 1MPa, carbonized at 900°C in nitrogen for 2 hours; prepared 0.1mol / L NaOH solution as the electrolyte, containing 0.2mol / L ammonia water, and the above coal-based carbon rods As the anode, the platinum sheet is the counter electrode, and the calomel electrode is the reference electrode. React for 2 hours under a bias voltage of 5V, collect the electrolyte containing a large number of carbon dots, and dialyze the electrolyte with a 3500Da dialysis bag to obtain nitrogen. doped carbon dots.

[0066] 2. Catalyst preparation: nitrogen-doped carbon dots and graphite oxide were prepared into a mixed solution at a mass ratio of 1:10, and hydrothermally treated at 180°C for 12 ...

Embodiment 2

[0077] 1. Preparation of nitrogen-doped carbon dots: crush and grind bituminous coal with high nitrogen content, sieve it to below 200 mesh, dry it in an oven at 110°C overnight, take 100g of coal powder and 20g of coal tar binder, and fully knead them. Stir evenly, extrude into a rod shape with a diameter of 10mm under the condition of 5MPa, and carbonize under the condition of 500°C in argon for 2 hours; prepare 0.05mol / L NaOH solution as the electrolyte solution, which contains 0.1mol / L ammonia water, and the above The coal-based carbon rod is used as the anode, the platinum sheet is used as the counter electrode, and the calomel electrode is used as the reference electrode. React for 6 hours under a bias voltage of 2V, collect the electrolyte containing a large number of carbon dots, and use a 3500Da dialysis bag to remove the electrolyte. , that is, nitrogen-doped carbon dots are obtained.

[0078] 2. Preparation of catalyst: Mix nitrogen-doped carbon dots and graphite ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com