Siloxy alkyl sulfur ether compound and preparation method thereof

A technology of siloxyalkyl sulfide and compound, which is applied in the field of siloxyalkyl sulfide compound and its preparation, can solve the problems of poor anti-vulcanization reversion performance of vulcanized rubber, and improve the anti-vulcanization reversion performance, Effect of shortening reaction time, improving processability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

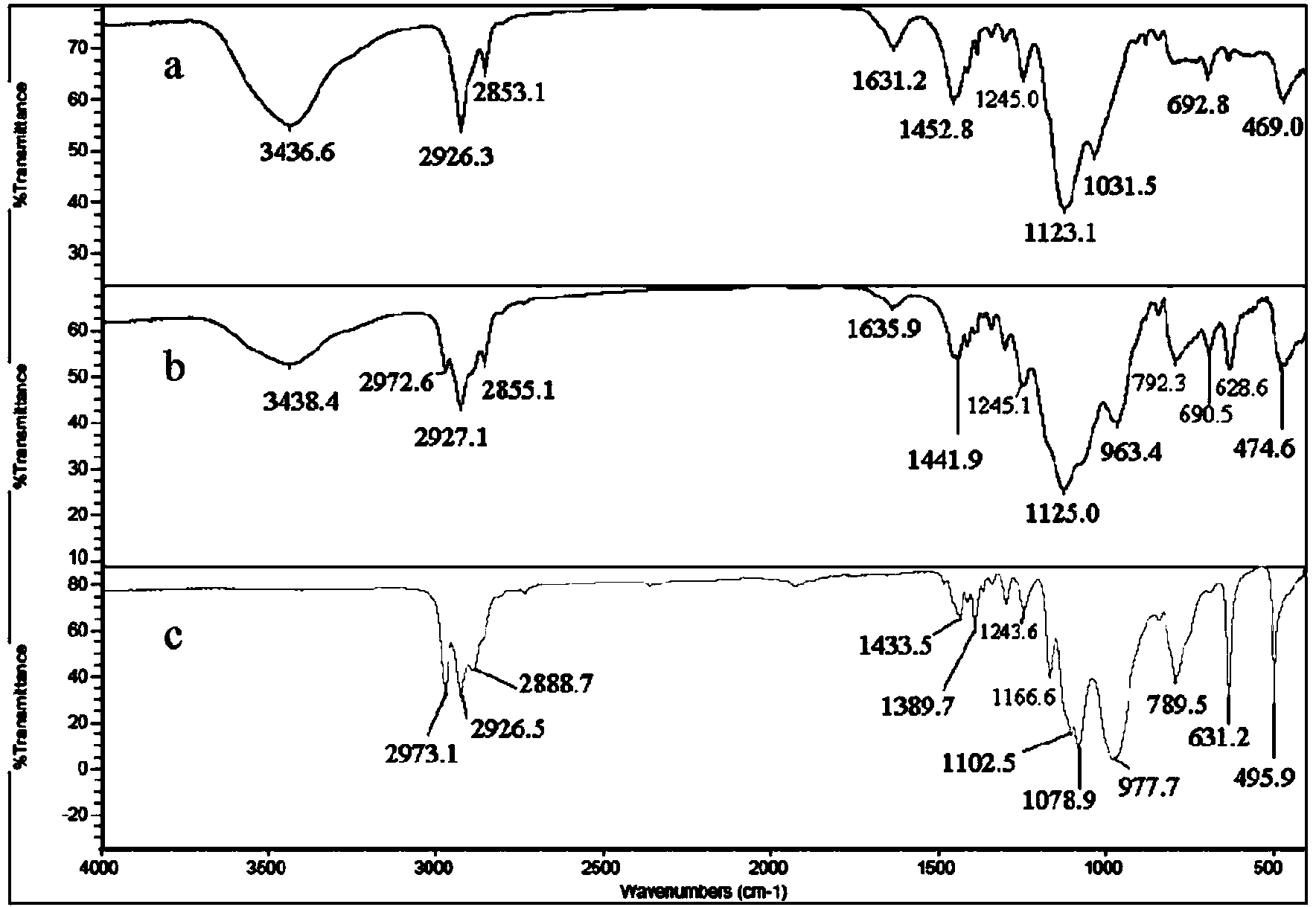

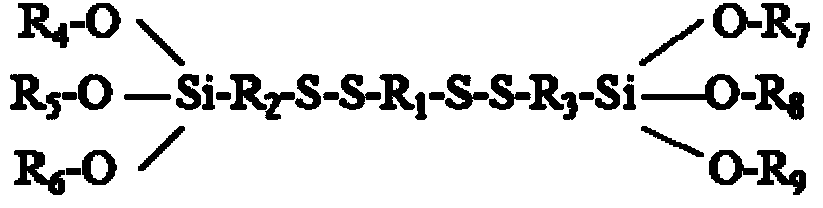

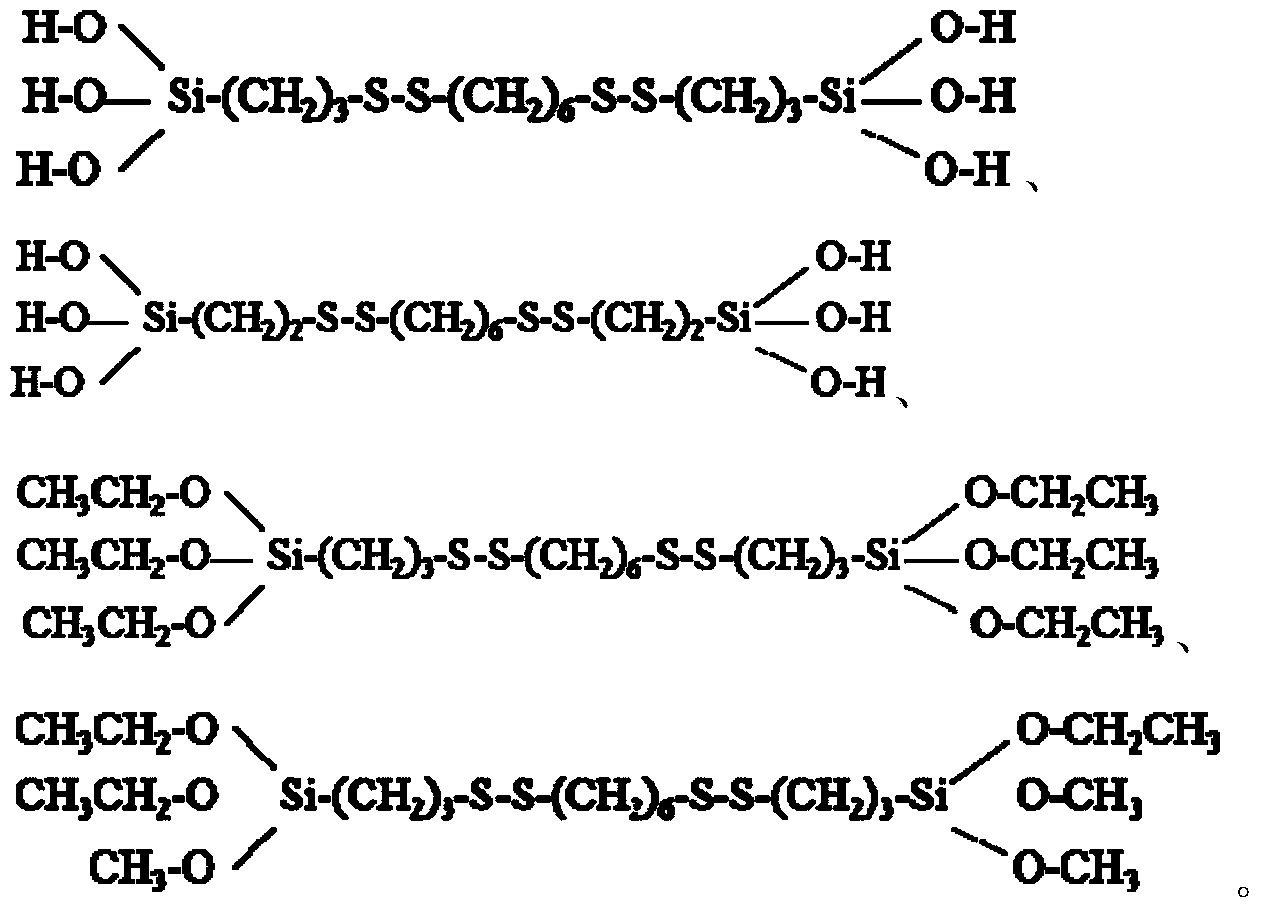

Image

Examples

Embodiment 1

[0038] A 100mL three-necked flask equipped with a stirring device, a thermometer, and a reflux condenser was used as a reaction vessel, and 15.0g (0.06mol) of γ-mercaptopropyltriethoxysilane (purchased from Bailingwei Technology Co., Ltd.) was added to the vessel. Stirring conditions Add 15.0 g of NaOH solution with a concentration of 30% by mass, and pour the solution into the dropping funnel after stirring for 10 min;

[0039] A 200mL four-neck flask equipped with a stirring device, a thermometer and a reflux condenser was used as a reaction vessel, and 11.7g (0.03mol) of hexamethylene 1,6-dithiosulfate disodium dihydrate (HTS, purchased from Flexsys ) into a four-neck flask, add 100g of water, stir to dissolve the HTS, drop the mercaptosilane solution in the dropping funnel, stir and react at 30°C for 4h, take a sample from the solution and pass it through liquid chromatography (HPLC) , with HTS as the internal standard, the residual HTS content in the solution is tested by...

Embodiment 2

[0044] A 100mL three-neck flask equipped with a stirring device, a thermometer, and a reflux condenser was used as a reaction vessel, and 10.6g (0.054mol) of γ-mercaptopropyltrimethoxysilane (purchased from Bailingwei Technology Co., Ltd.) was added to the vessel. Add 15.0 g of NaOH solution with a mass percent concentration of 30%, and pour the solution into the dropping funnel after stirring for 10 min;

[0045] A 200mL four-necked flask equipped with a stirring device, a thermometer, and a reflux condenser was used as a reaction vessel, and 11.7g (0.03mol) of HTS was weighed and added to the four-necked flask, and 100g of water was added, stirred to dissolve the HTS, and then added dropwise After the mercaptosilane solution in the funnel was stirred and reacted at 30° C. for 4 hours, the residual HTS content in the solution was tested according to the HPLC test method in Example 1 to be about 0.03%, and the conversion rate was calculated to be about 99.5%.

[0046] Stop sti...

Embodiment 3

[0049] A 100mL three-necked flask equipped with a stirring device, a thermometer and a reflux condenser was used as a reaction vessel, and 13.5g (0.06mol) of 2-mercaptoethyltriethoxysilane was added to the vessel, and 15.0g of mass percent concentration was added under stirring conditions. 20% NaOH solution, after stirring for 10 minutes, pour the solution into the dropping funnel;

[0050] A 200mL four-necked flask equipped with a stirring device, a thermometer, and a reflux condenser was used as a reaction vessel, and 11.7g (0.03mol) of HTS was weighed and added to the four-necked flask, and 100g of water was added, stirred to dissolve the HTS, and then added dropwise After the mercaptosilane solution in the funnel was stirred and reacted at 30° C. for 4 hours, the residual HTS content in the solution was tested according to the HPLC test method in Example 1 to be about 0.05%, and the conversion rate was calculated to be about 99.4%.

[0051] Stop stirring, filter the above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com