Hollow polymer emulsion particle and preparation method

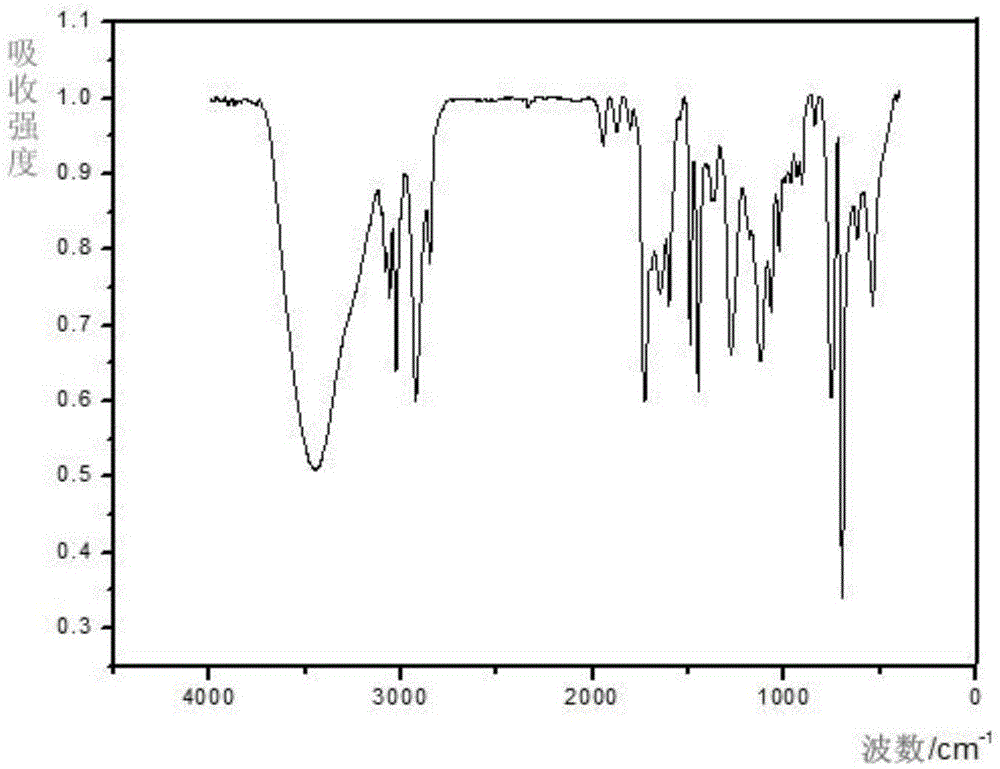

A technology of polymer latex and polymer emulsion, applied in the field of hollow polymer latex particles and their preparation, can solve problems such as easy rupture and collapse, achieve excellent shading performance and deformability, ensure stability and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

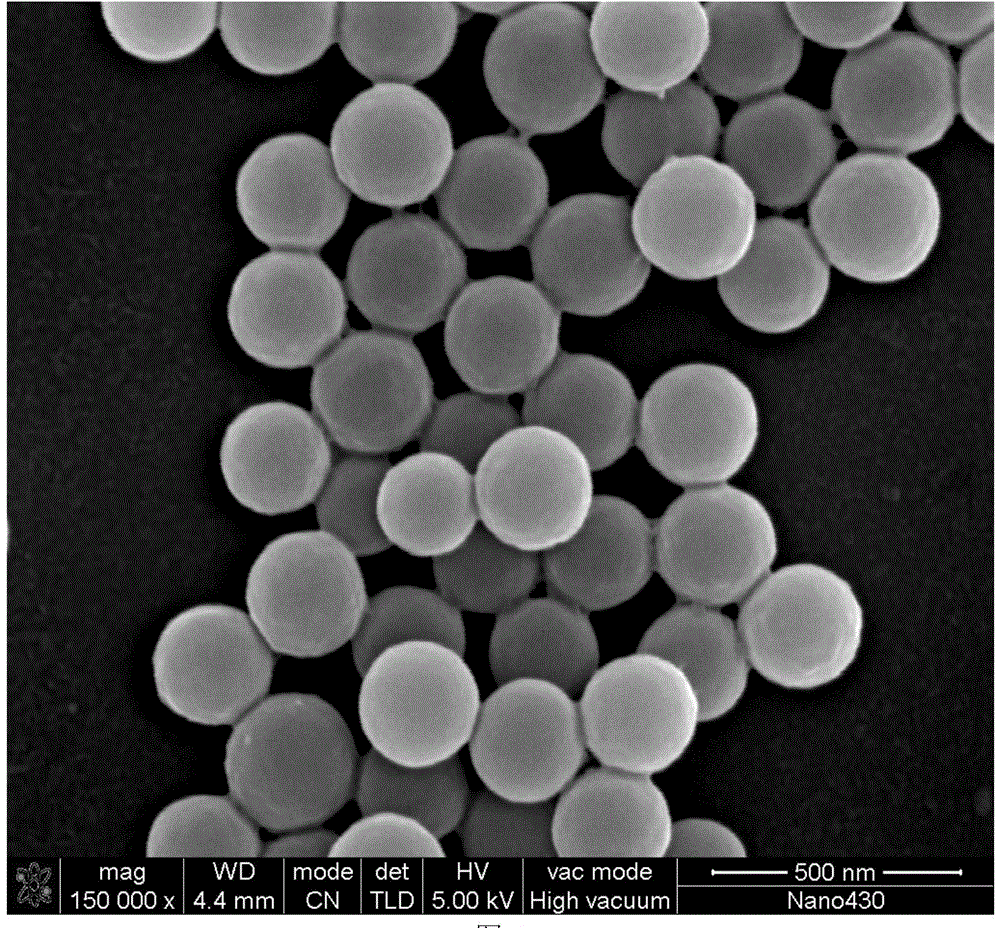

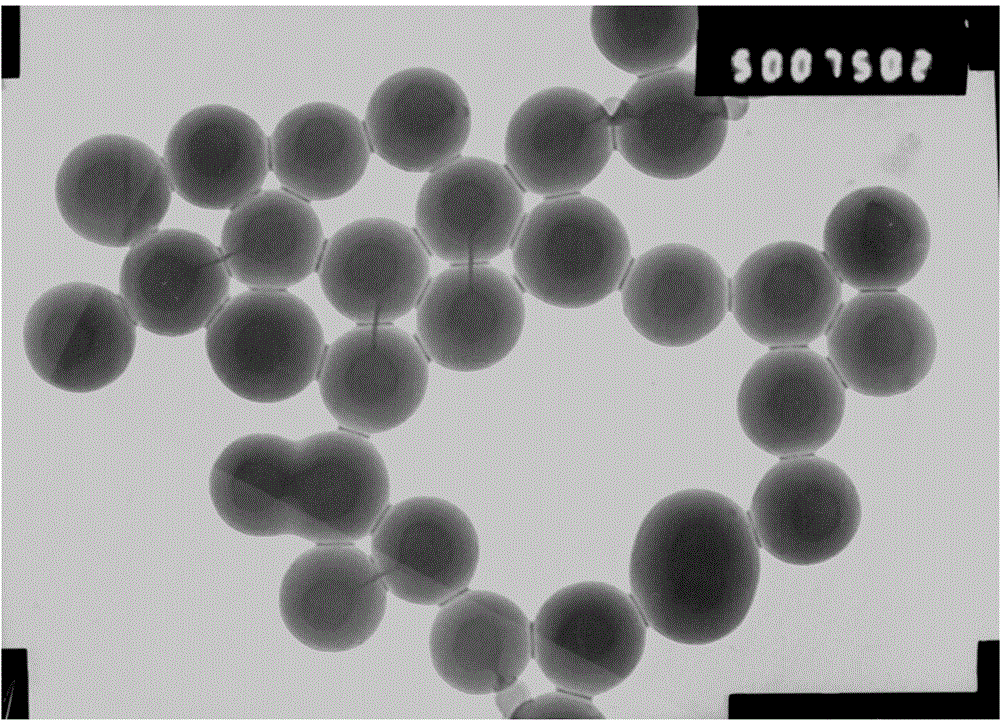

Embodiment 1

[0033] Seed emulsion preparation: Mix and stir 50g deionized water and 0.0126g anionic emulsifier SDBS, gradually heat up the deionized water and emulsifier system to 85°C, then add 0.2g initiator sodium persulfate and 0.225g methacrylic acid Add the mixture composed of 2.2g of styrene at one time, stir and mix evenly, and make a seed emulsion for use after a reaction time of 1h.

[0034]Add 120g of deionized water, 20.5g of isooctane, and 9.25g of methanol into a 1000ml round-bottom four-neck flask equipped with a stirring paddle, a thermometer, a reflux condenser, and a nitrogen inlet valve, and then add the monomer mixture in sequence (by mixing 60g of benzene ethylene, 1.2g methacrylic acid), add another 3g dodecyl mercaptan, and then under the condition of stirring, heat up until the temperature rises to 85°C, then slowly add the seed emulsion prepared above, dropwise for 1h , forming a pre-emulsion. The aqueous solution containing the initiator (made by mixing 120g of d...

Embodiment 2

[0039] Seed emulsion preparation: Mix and stir 50g deionized water and 0.0126g anionic emulsifier SDBS, gradually heat up the deionized water and emulsifier system to 85°C, then add 0.2g initiator sodium persulfate and 0.225g methacrylic acid Add the mixture composed of 2.2g of styrene at one time, stir and mix evenly, and make a seed emulsion for use after a reaction time of 1h.

[0040] Add 120g of deionized water, 29.75g of isooctane, and 9.25g of methanol into a 1000ml round-bottom four-neck flask equipped with a stirring paddle, a thermometer, a reflux condenser, and a nitrogen inlet valve, and then add the monomer mixture in sequence (by mixing 60g of benzene ethylene, 1.2g methacrylic acid), add another 3g dodecyl mercaptan, and then under the condition of stirring, heat up until the temperature rises to 85°C, then slowly add the seed emulsion prepared above, dropwise for 1h , forming a pre-emulsion. Add 50% of the total amount of the mixed solution containing the init...

Embodiment 3

[0043] Seed emulsion preparation: Mix and stir 50g deionized water and 0.0126g anionic emulsifier SDBS, gradually heat up the deionized water and emulsifier system to 80°C, then add 0.2g initiator sodium persulfate and 0.225g methacrylic acid Add the mixture composed of 2.2g of styrene at one time, stir and mix evenly, and make a seed emulsion for use after a reaction time of 1h.

[0044] Add 100g of deionized water, 29.75g of isooctane, and 12g of methanol into a 1000ml round-bottom four-neck flask equipped with a stirring paddle, a thermometer, a reflux condenser, and a nitrogen inlet valve, and then add the monomer mixture in sequence (by mixing 58g of styrene , 2.5g of methacrylic acid), add 2.5g of dodecyl mercaptan, and then heat up under stirring until the temperature rises to 85°C, then slowly add the above-prepared seed emulsion for 1h , forming a pre-emulsion. Add 50% of the total amount of the mixed solution containing the initiator (made by mixing 120g deionized w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com