A preparation method of carbon-coated cuprous oxide and carbon-coated cuprous oxide

A technology of cuprous oxide and carbon coating, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. Complicated process and other issues, to achieve the effect of large output, good shape and tight combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

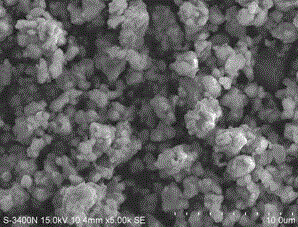

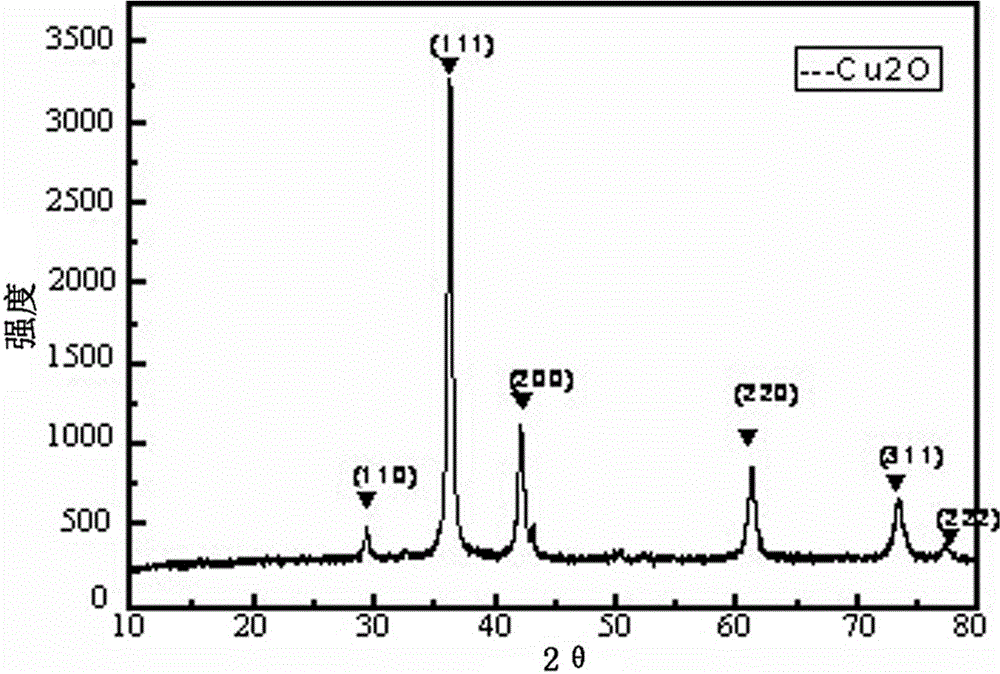

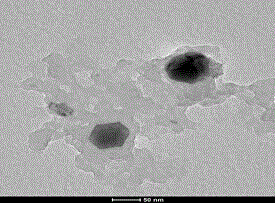

Embodiment 1

[0060] Stir 2g of homemade liquid acrylonitrile oligomer solution LPAN (molecular weight 4000) at 120°C for 120h to form a microcyclized LPAN solution, heat treat the microcyclized LPAN solution at 200~300°C for 8h, and form a Thermally oxidized polyacrylonitrile oligomer (OPAN) solid with trapezoidal structure, add 11.25g of copper oxide, 15-30ml of solvent, and use a planetary ball mill to grind the sample with a ball-to-material ratio of 15:1, 400rad / min ball mill for 10h, and produce After feeding, it was dried in an oven at 220°C for 3 hours to obtain a thermally oxidized precursor. Put the thermal oxidation precursor in a porcelain boat, and under the protection of an inert atmosphere, the gas flow rate is 150ml / min, calcined at 350°C for 4h, and cooled to room temperature to obtain a mixture of carbon-coated copper and carbon-coated cuprous oxide. The product structure is as follows Figure 1 to Figure 3 shown.

Embodiment 2

[0062] Stir 4g of polypyrrole (molecular weight 4000) at 120°C for 120h to form a micro-cyclized solution, heat-treat the micro-cyclized solution at 200-300°C for 8h to form thermally oxidized pyrrole oligomers with a certain ladder structure (OPly) solid, add 10g of copper oxide, 15-30ml of solvent, and ball mill the sample with a planetary ball mill, the ball-to-material ratio is 15:1, 400rad / min ball mill for 8h, after discharging, dry in an oven at 220°C for 3h to obtain the pre-thermal oxidation body. Put the thermal oxidation precursor in a porcelain boat, under the protection of an inert atmosphere, the gas flow rate is 150ml / min, calcined at 300°C for 4h, and cooled to room temperature to obtain a mixture of a small amount of carbon-coated cuprous oxide and carbon-coated cupric oxide, the product structured as Figure 4 with Figure 5 shown.

Embodiment 3

[0064] Stir 10g of polythiophene (molecular weight 4000) at 120°C for 120h to form a microcyclized polythiophene solution, then heat-treat the microcyclized polythiophene solution at 200~300°C for 8h to form a thermally oxidized polythiophene solution with a certain trapezoidal structure. Thiophene oligomer (OPTh) solid, add 6.25g copper oxide, 15-30ml deionized water as a solvent, and use a planetary ball mill to grind the sample with a ball-to-material ratio of 15:1, 400rad / min ball mill for 8h, after discharging, 220 ℃ oven drying for 3h to obtain the thermal oxidation precursor. Put the thermal oxidation precursor in a porcelain boat, under the protection of an inert atmosphere, with a gas flow rate of 150ml / min, calcinate at 250°C for 4h, and cool to room temperature to obtain a mixture of carbon-coated cuprous oxide and a small amount of carbon-coated cupric oxide, the product structured as Image 6 with Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com