Preparation method of carbon-coated ferrous oxide and carbon-coated ferrous oxide

A technology of ferrous oxide and carbon coating, applied in the direction of iron oxide/hydroxide, etc., can solve the problems of fast release speed, short anti-fouling life, unstable existence of ferrous oxide, etc., achieve low cost, prevent oxidation, The tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

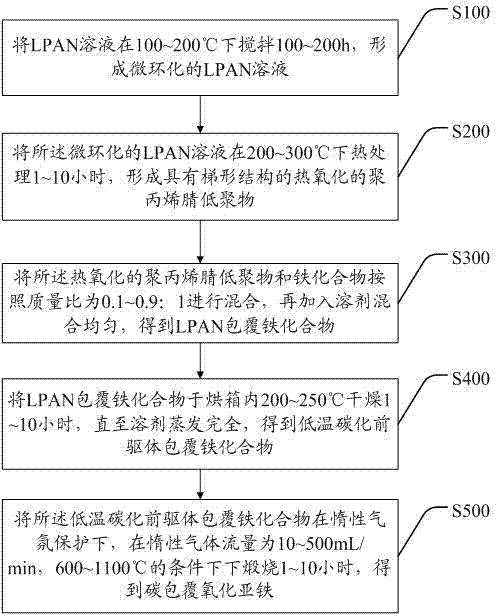

Method used

Image

Examples

Embodiment 1

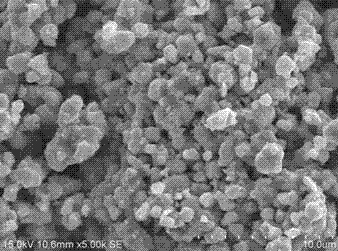

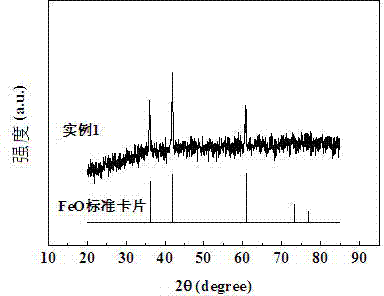

[0053] Stir 2g of LPAN solution (molecular weight 4000) at 120°C for 120h to form a microcyclized LPAN solution, heat-treat the microcyclized LPAN solution at 250°C for 8h to form a thermally oxidized polyacrylonitrile oligomer with a ladder structure (OPAN) solid, add 6g of iron oxide, 15ml of solvent, and ball mill the sample with a planetary ball mill, the ball to material ratio is 15:1, 400rad / min ball mill for 10h, after discharging, dry in an oven at 220°C for 3h to obtain the thermal oxidation precursor ( That is, low-temperature carbonization precursor coated iron compound). Put the thermal oxidation precursor in a porcelain boat, under the protection of an inert atmosphere, the gas flow rate is 150ml / min, calcined at 600°C for 4h, cooled to room temperature, carbon-coated ferrous oxide mixture, the product structure is as follows Figure 1 to Figure 2 shown.

Embodiment 2

[0055] Stir 2g of LPAN solution (molecular weight 10,000) at 200°C for 100h to form a microcyclized LPAN solution, heat-treat the microcyclized LPAN solution at 200°C for 10h to form a thermally oxidized polyacrylonitrile oligomer with a ladder structure (OPAN) solid, add 15g iron oxide, 20ml solvent, and ball mill the sample with a planetary ball mill, the ball to material ratio is 15:1, 400rad / min ball mill for 8h, after discharging, dry in 200℃ oven for 10h to obtain the thermal oxidation precursor ( That is, low-temperature carbonization precursor coated iron compound). Put the thermal oxidation precursor in a porcelain boat, under the protection of an inert atmosphere, with a gas flow rate of 10ml / min, calcinate at 1100°C for 10h, cool to room temperature, and carbon-coat the ferrous oxide mixture.

Embodiment 3

[0057] Stir 2g of LPAN solution (molecular weight 1600) at 100°C for 200h to form a microcyclized LPAN solution, heat-treat the microcyclized LPAN solution at 300°C for 1h to form a thermally oxidized polyacrylonitrile oligomer with a ladder structure (OPAN) solid, add 3g iron oxide, 30ml solvent, and ball mill the sample with a planetary ball mill, the ball to material ratio is 15:1, 400rad / min ball mill for 12h, after discharging, dry in an oven at 250°C for 1h to obtain the thermal oxidation precursor ( That is, low-temperature carbonization precursor coated iron compound). Put the thermal oxidation precursor in a porcelain boat, under the protection of an inert atmosphere, with a gas flow rate of 500ml / min, calcinate at 1100°C for 1h, cool to room temperature, and carbon-coat the ferrous oxide mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com