Active substance, electrode, secondary battery, battery pack, and electric vehicle

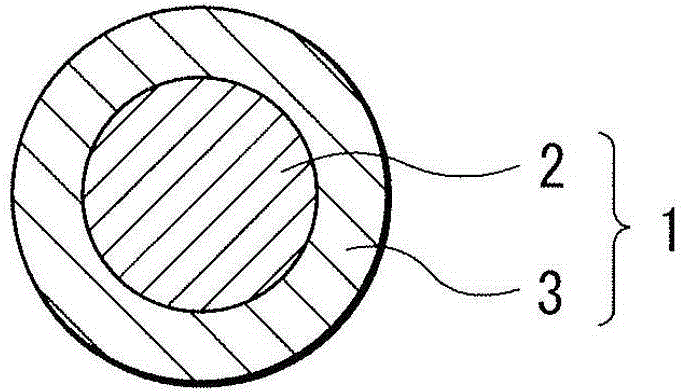

A secondary battery and active material technology, applied in the direction of active material electrodes, secondary batteries, electric vehicles, etc., can solve the problem of reducing battery characteristics and achieve the effect of excellent battery characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1 to 1-8

[0261] Manufactured in the following process Figure 9 and Figure 10 The laminated film type lithium ion secondary battery shown in .

[0262] When manufacturing the positive electrode 53, first, 91 parts by mass of the positive electrode active material (LiCoO 2 ), 6 parts by mass of a positive electrode conductor (graphite) and 3 parts by mass of a positive electrode binder (polyvinylidene fluoride: PVDF) were mixed to obtain a positive electrode mixture. Subsequently, the cathode mixture was dispersed in an organic solvent (N-methyl-2-pyrrolidone: NMP) to obtain paste cathode mixture slurry. Subsequently, both surfaces of the positive electrode current collector 53A (a strip-shaped aluminum foil having a thickness of 12 μm) were uniformly coated with the positive electrode mixture slurry using a coating device, and the coated positive electrode mixture slurry was dried to form a positive electrode active material layer 53B. Finally, the cathode active material layer 53...

Embodiment 2-1 to 2-11

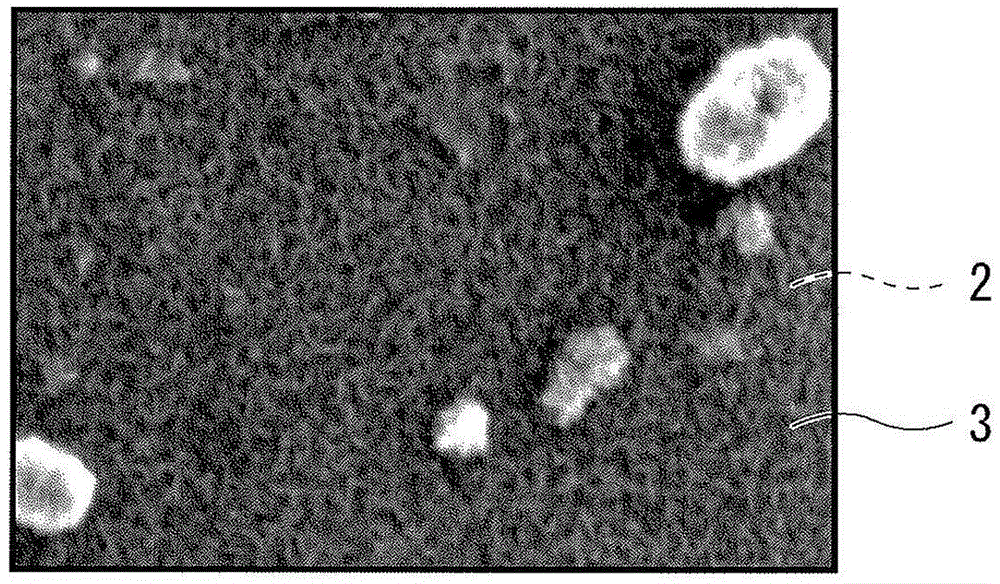

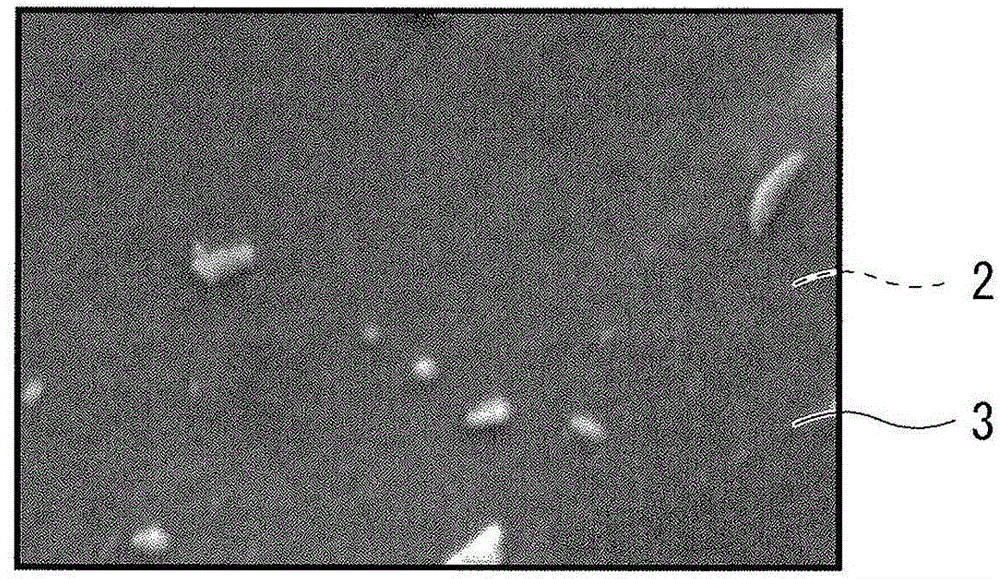

[0279] Through a procedure similar to that of Example 1-1, secondary batteries were manufactured, but as shown in Table 2, the ratio D1 / D2 and the ratio D1 / D3 were changed, and various characteristics were examined. In these examples, the ratio D1 / D2 and the ratio D1 were adjusted by changing conditions such as the ratio between methane gas and acetylene gas, the heating temperature, and the type of auxiliary gas in the step of forming the covering portion by the thermal decomposition CVD method. / D3.

[0280] 【Table 2】

[0281]

[0282] In the case where specific ions are detected by the positive ion analysis of the covering part, when the ratio D1 / D2 is equal to or greater than 1.25, a high initial efficiency equal to or greater than 70% and a high capacity retention ratio equal to or greater than 80% are obtained, and The case where the ratio D1 / D2 is less than 1.25 is different. When the ratio D1 / D2 is equal to or greater than 50, the initial efficiency and the capaci...

Embodiment 3-1 to 3-9

[0284] Through a procedure similar to that of Example 1-1, secondary batteries were manufactured, but as shown in Table 3, the average thickness and average coverage of the covering portion were changed, and various characteristics were examined. In these examples, in the step of forming the covered part, the average thickness is adjusted by changing conditions such as deposition rate and deposition time, and the average coverage is adjusted by changing conditions such as input power and deposition time.

[0285] 【table 3】

[0286]

[0287] High initial efficiency and high capacity retention ratio are obtained independently of the average thickness of the covering. However, in the case where the average thickness is greater than 500 nm, since the formation amount of the covering portion is too large, the battery capacity decreases. Therefore, in the case where the average thickness is equal to or less than 500 nm, high initial efficiency and high capacity retention ratio a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com