Titanic acid compound, process for producing the titanic acid compound, electrode active material containing the titanic acid compound, and storage device using the electrode active material

A technology of titanate compounds and organic compounds, applied in titanium compounds, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of low discharge potential of graphite, safety concerns, etc., and achieve high capacity and excellent cycle characteristics , The effect of excellent battery characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

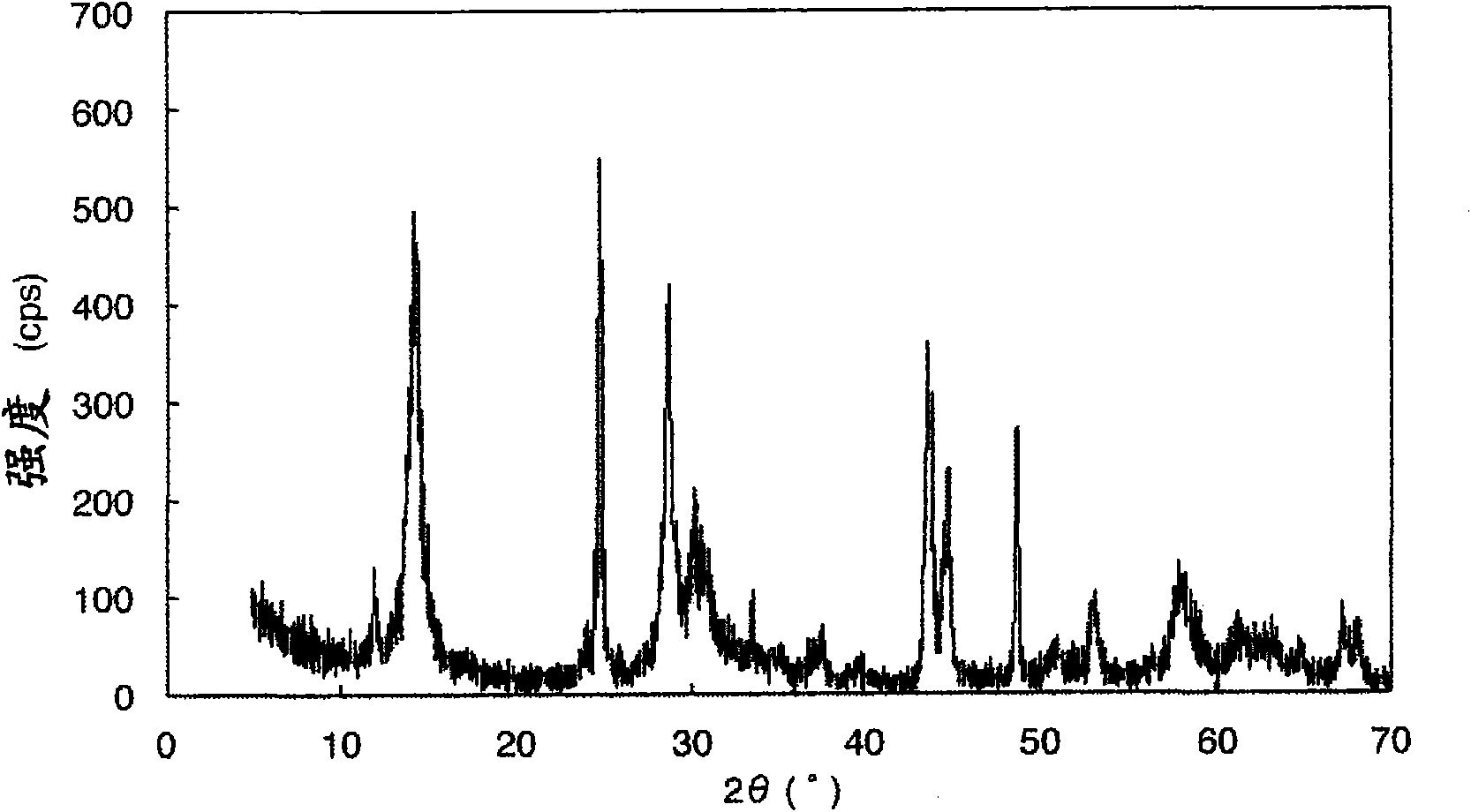

Embodiment 1

[0040] 20.0 grams of commercially available rutile-type high-purity titanium dioxide (PT-301, manufactured by Ishihara Sangyo Kaisha Ltd.) and 8.85 grams of sodium carbonate were uniformly mixed. The mixture was heated and calcined in the air at a temperature of 800° C. for 20 hours using an electric furnace. After heating and calcining, the resultant is cooled, thoroughly mixed, and then heated and calcined under the same conditions to obtain Na 2 Ti 3 O 7 . The resulting Na 2 Ti 3 O 7 Add to the concentration of 1 molar hydrochloric acid aqueous solution to make Na 2 Ti 3 O 7 The concentration becomes 10 g / L, and it is allowed to react at room temperature for 4 days under stirring to obtain H 2 Ti 3 O 7 . Here, during these 4 days, the solid content was allowed to settle and the aqueous hydrochloric acid solution was replaced every day. Filtered H 2 Ti 3 O 7 , Washed, and dried in air at 60°C for 12 hours, and then thermally dehydrated in air at 260°C for 20 hours using an e...

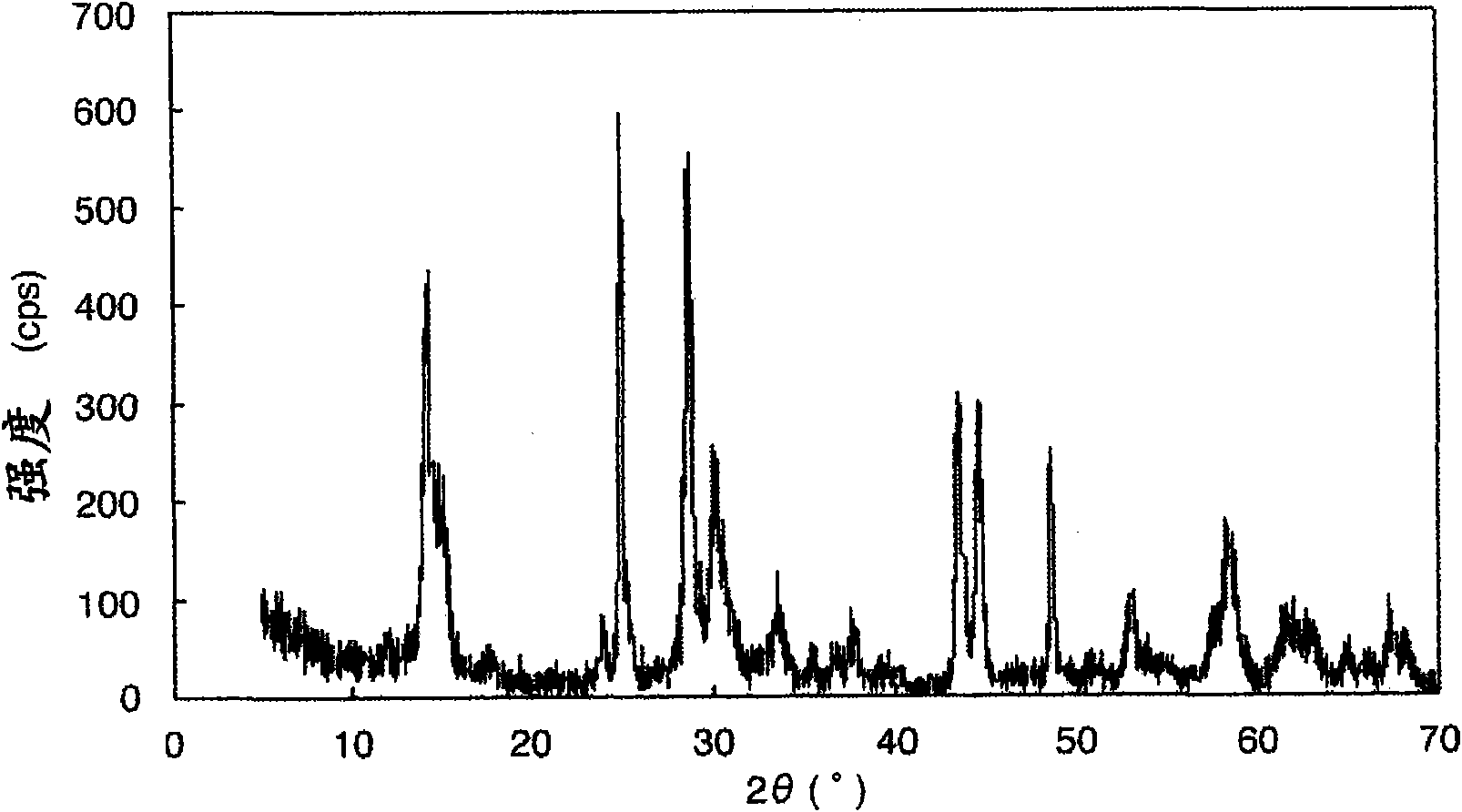

Embodiment 2 to 4

[0043] The titanic acid compound of the present invention (Examples 2 and 3: Samples B and C) was obtained as in Example 1, except that the heating temperature in Example 1 was changed to 300°C or 320°C.

[0044] The titanic acid compound of the present invention (Example 4: Sample D) was obtained as in Example 1, except that the heating temperature was set to 290°C and the heating time was set to 5 hours.

[0045] Their heat loss in the temperature range of 300 to 600°C is 0.8% by weight, 0.7% by weight and 1.8% by weight, respectively.

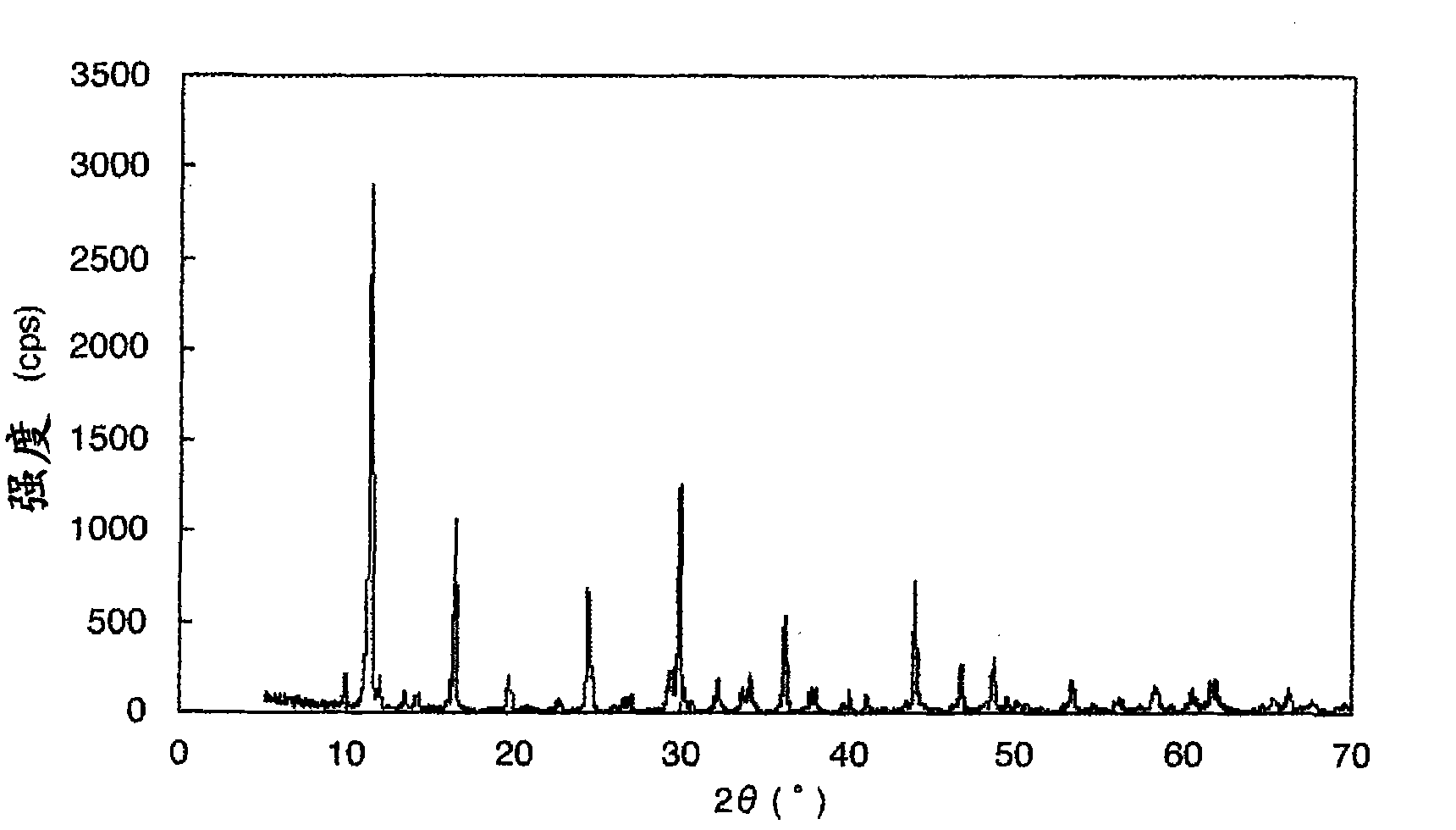

Embodiment 5

[0047] Using a spray dryer (model: MDL-050C, manufactured by Fujisaki Electric Co., Ltd.), at an inlet temperature of 200°C and an outlet temperature of 70 to 90°C, the TiO 2 A total of 282.0 grams of orthotitanic acid and 5,638 grams of an aqueous slurry of 124.7 grams of sodium carbonate were spray dried to obtain a dry granulated material. The resulting dried granulated material was heated and calcined in the air at a temperature of 800° C. for 20 hours using an electric furnace. After heating and calcining, the resultant is cooled, thoroughly mixed, and then heated and calcined under the same conditions to obtain Na 2 Ti 3 O 7 Of granulated materials. The resulting Na 2 Ti 3 O 7 The granulated material is added to the 1 molar hydrochloric acid aqueous solution to make Na 2 Ti 3 O 7 The concentration becomes 10 g / L, and it is allowed to react under stirring for 4 days at room temperature to obtain H 2 Ti 3 O 7 Of granulated materials. Here, during these 4 days, the solid con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com