Vacuum assisted resin transfer molding integral-forming technology of composite material fuel-tank

A technology of resin transfer molding and composite materials, which is applied in the field of molding technology and soluble (melting) mandrels, can solve the problems of poor product shape and dimensional accuracy, low strength of plastic fuel tanks, poor corrosion resistance, etc., to achieve Beautiful appearance, excellent sound insulation, and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

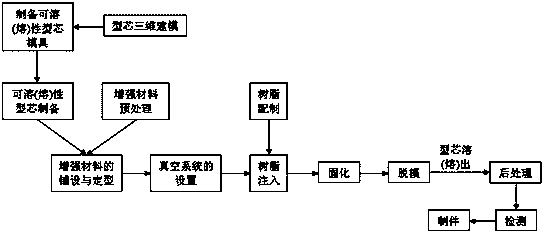

Method used

Image

Examples

Embodiment 1

[0030] Including the following steps:

[0031] 1. Three-dimensional modeling of the core: make the core drawing according to the design size of the fuel tank, and then use the three-dimensional modeling software UG, ProE, Solid works, CATIA, etc. Carry out cutting, select 10 representative sections in the fuel tank core model, and reduce the dimensions around the 10 sections by 30mm on each side, and print out the reduced section graphics file to form a drawing.

[0032] 2. Preparation of the core model of the third outer fuel tank: According to the CAD cross-sectional drawing of the core established by three-dimensional modeling, 10 FRP partitions in different positions were made, and all the partitions were fixed in series in sequence and position with triangle irons. Together, form a frame; and pour polyurethane foam material between the partitions, after the foaming is complete, trim it according to the size of the partition, and then use epoxy resin LT-5078, biaxial E-BX8...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that the water-soluble core is replaced by a meltable core. details as follows:

[0050] In step 3, the preparation of the fusible core: first, remake the core forming mold according to the core model, the same as in Example 1; after that, select an alloy material with a melting point within 100°C (such as Bi with a melting point of 102.5°C, Sn, Cd ternary alloy, the weight ratio is 54:26:20) as raw material, configure the low melting point mandrel material that can meet the molding requirements, melt the fusible alloy material, and use the fusible core casting mold to cast Shape and sand the surface of the fusible core (step 4).

[0051] In step 13, the fusible core of the third outer fuel tank is melted out: the composite fuel tank part with the fusible core is placed in a hot oven at 105°C until the fusible core is completely melted, and poured out. A third outer fuel tank product made of composite material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com