Ecological environment-friendly urea chelated compound fertilizer and preparation method thereof

A compound fertilizer and chelation technology, applied in the direction of fertilization device, fertilizer mixture, application, etc., to achieve the effect of alleviating the antagonism between ions and improving the utilization rate of fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

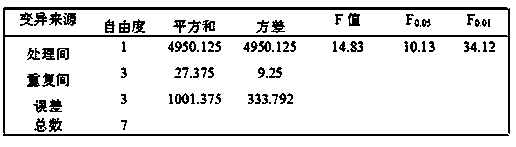

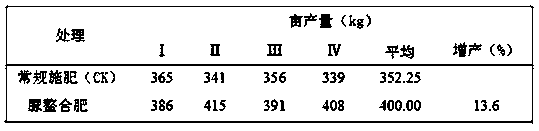

Examples

Embodiment 1

[0021] Add 22kg of zinc sulfate and 18kg of borax to 94kg of compound amino acids, adjust the pH to about 7, and carry out a stirring reaction to make the compound amino acids chelate with boron and zinc; add 317kg of urea, 227kg of monoammonium phosphate, 250kg of potassium chloride, 20kg of diatomaceous earth compound fertilizer filler, 2kg of chelating compound fertilizer anti-caking agent, and then pulverize and stir; add urea-formaldehyde solution for spraying and granulation, in which the formaldehyde solution is first injected into the urine formaldehyde preparation tank through the formaldehyde solution pump, After stirring, inject molten urea with a concentration of 96.5% through a molten urine pump to fully mix it with formaldehyde solution, then add NaOH solution with a concentration of 50% to adjust the pH value of the mixture to 7.2; finally inject steam , so that the final temperature rose to 75 ° C. After reacting for 30-45 minutes, a urea-formaldehyde solution ...

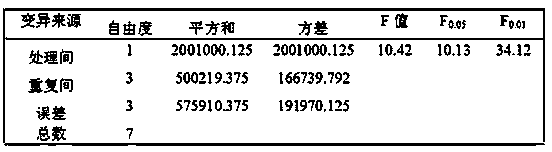

Embodiment 2

[0028] Add 22kg of zinc sulfate and 18kg of borax to 94kg of compound amino acids, adjust the pH to about 7, and carry out a stirring reaction to make the compound amino acids chelate with boron and zinc; add 259kg of urea, 227kg of monoammonium phosphate, 250kg of potassium chloride, 8kg of diatomaceous earth compound fertilizer filler, 2kg of chelating compound fertilizer anti-caking agent, and then pulverize and stir; add urea-formaldehyde solution for spraying and granulation, wherein the formaldehyde solution is first injected into the urine formaldehyde preparation tank through the formaldehyde solution pump, After stirring, inject molten urea with a concentration of 96.5% through a molten urine pump to fully mix it with formaldehyde solution, then add NaOH solution with a concentration of 50% to adjust the pH value of the mixture to 7.2; finally inject steam , so that the final temperature rose to 75 ° C. After reacting for 30-45 minutes, a urea-formaldehyde solution wi...

Embodiment 3

[0032] Add 22kg of zinc sulfate and 18kg of borax to 94kg of compound amino acids, adjust the pH to about 7, and carry out a stirring reaction to make the compound amino acids chelate with boron and zinc; add 292kg of urea, 227kg of monoammonium phosphate, 250kg of potassium chloride, 15kg of diatomaceous earth compound fertilizer filler, 2kg of chelating compound fertilizer anti-caking agent, and then pulverized and stirred; then urea-formaldehyde solution was sprayed and granulated, wherein the formaldehyde solution was first injected into the urine formaldehyde preparation tank through the formaldehyde solution pump, After stirring, inject molten urea with a concentration of 96.5% through a molten urine pump to fully mix it with formaldehyde solution, then add NaOH solution with a concentration of 50% to adjust the pH value of the mixture to 7.2; finally inject steam , so that the final temperature rose to 75 ° C. After reacting for 30-45 minutes, a urea-formaldehyde soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com