Method for preparing ethylene glycol diacetate

A technology of ethylene glycol diacetate, applied in the field of preparation of ethylene glycol diacetate, can solve the problems of producing a large amount of solid waste and waste water, low product selectivity, low production efficiency, etc., and achieve good Economic and environmental benefits, simple operation, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

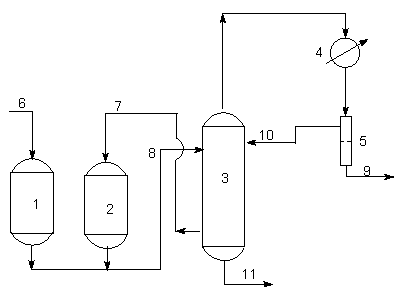

[0021] process such as figure 1 As shown, the raw materials ethylene glycol and acetic acid preheated to 105°C are fed in a molar ratio of 1:3.5 at a flow rate of 15 L / h continuously into a 5 L composite reinforced macroporous polystyrene sulfonic acid type strongly acidic cation exchange resin. The first-stage fixed-bed reactor 1 with solid acid catalyst, the esterification reaction temperature is 105°C, and the space velocity is 3 h -1 . The material reacted in the first fixed-bed reactor 1 enters the distillation tower 3. In the distillation tower 3, the water generated by the esterification reaction forms an azeotrope at 68-71 °C in the presence of water-carrying agent benzene and is continuously absorbed separate. The material that is dehydrated is extracted continuously with 30 L / h flow rate in the stripping section of distillation tower 3 and is transported to the second stage fixed-bed reactor 2 that 5 L of above-mentioned solid acid catalysts are housed to continue ...

Embodiment 2

[0023] process such as figure 1 As shown, the raw materials ethylene glycol and acetic acid preheated to 110°C with a molar ratio of 1:4.5 were continuously input at a flow rate of 20 L / h into a 5 L composite reinforced macroporous polystyrene sulfonic acid type strongly acidic cation exchange resin. The first-stage fixed-bed reactor 1 with solid acid catalyst, the esterification reaction temperature is 110°C, and the space velocity is 4 h -1 . The materials reacted in the first fixed-bed reactor 1 enter the distillation tower 3, and in the distillation tower 3, the water generated by the esterification reaction forms an azeotrope at 69-71 °C in the presence of cyclohexane water-carrying agent and continuously was separated. The esterification reaction material that removes moisture is extracted continuously with 40 L / h flow rate in the stripping section of distillation tower 3 and is transported to the second section fixed-bed reactor 2 that 5 L of above-mentioned solid aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com