Industrial preparation method of high-reaction-activity nano calcium hydroxide powder

A high-reactivity, calcium hydroxide technology, applied in the direction of calcium/strontium/barium oxide/hydroxide, can solve the problems of difficult achievement transformation and technology promotion, poor process economy and operability, etc., to achieve The effect of low-cost, high-efficiency industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

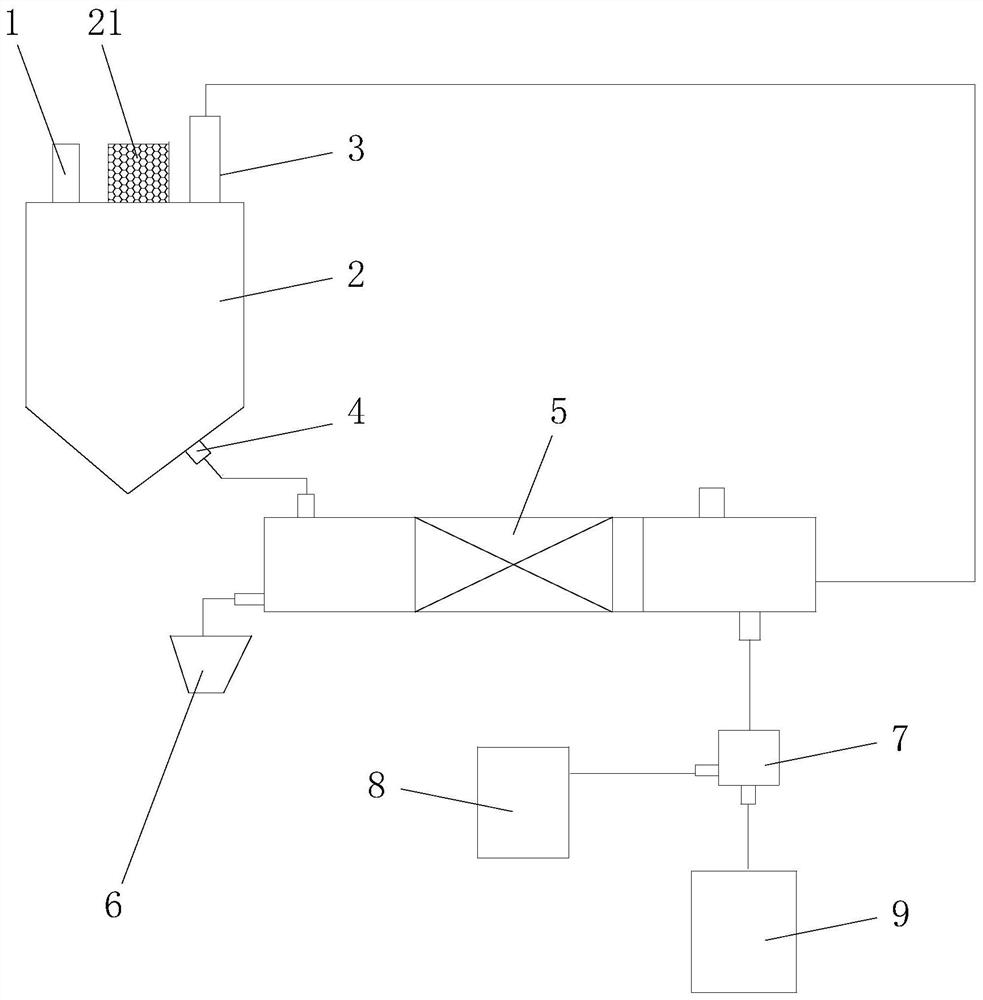

[0034] see figure 1 Schematic diagram of the technological process, the steps are as follows:

[0035] (1) Na with 5% mass concentration 2 CO 3 The limestone impregnated with the solution is calcined in the vertical kiln (the temperature in the calcining zone is 1000 ℃ ~ 1100 ℃) to prepare quicklime with high activity and low impurity content;

[0036] (2) After the above-mentioned quicklime is sieved through a 120-mesh drum sieve to remove impurities such as coal ash powder, the massive quicklime is machine-crushed by a jaw crusher to obtain calcium oxide particles with a particle size of 5-10 mm (referred to as high-activity calcium oxide, and the following examples are all referred to as This is the raw material);

[0037] (3) 150 kg of water and 250 kg of the above-mentioned calcium oxide particles are fed into the pre-mixing reactor 2 through the metering pump and the metering scale successively from the feeding port 1. The pre-mixing reactor is equipped with a stirrin...

Embodiment 2

[0042] (1) Same as step (1) in Example 1;

[0043] (2) Same as step (2) of Example 1;

[0044] (3) 150 kg of digestion solution (3% glucose aqueous solution) and 250 kg of highly active calcium oxide are added to the pre-digester through metering pumps and metering scales successively, and pre-mixed and hydrated for digestion under stirring conditions. Continue under positive pressure for about 15 minutes (the internal pressure of the container is ≤0.08MPa, the pressure control details are the same as in Example 1), and a first-grade powder with a moisture content of about 6% is obtained;

[0045] (4) After the primary reaction is completed, open the outlet valve at the bottom of the pre-mixing reactor, and the primary powder is sprayed into the inner cavity of the long-stroke double-screw digester under pressure for full digestion. The high-temperature steam generated by the primary digestion reaction is introduced into the outer jacket of the long-stroke double-screw digest...

Embodiment 3

[0048] (1) Same as step (1) in Example 1;

[0049] (2) Same as step (2) of Example 1;

[0050] (3) 150 kg of digestion solution (an aqueous solution containing 1% propylene glycol and 1% mass concentration of cyclodextrin) and 250 kg of highly active calcium oxide are added to the pre-digester through metering pumps and metering scales successively, under stirring conditions Carry out premixing and hydration digestion, and the reaction lasts for about 15 minutes under slight positive pressure (container internal pressure ≤ 0.1MPa, pressure control details are the same as in Example 1), to obtain a first-grade powder with a moisture content of about 7%;

[0051] (4) After the primary reaction is completed, open the outlet valve at the bottom of the pre-mixing reactor, and the primary powder is sprayed into the inner cavity of the long-stroke double-screw digester under pressure for full digestion. The high-temperature steam generated by the first-stage digestion reaction is in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com