Alkali-free short glass fiber reinforced nylon material and preparation method

A short glass fiber and nylon technology is applied in the field of alkali-free short glass fiber reinforced nylon material and its preparation, which can solve the problems of complicated process, unfavorable uniform glass fiber dispersion, inconvenient glass fiber addition, etc. The effect of ideal capacitance and excellent material stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

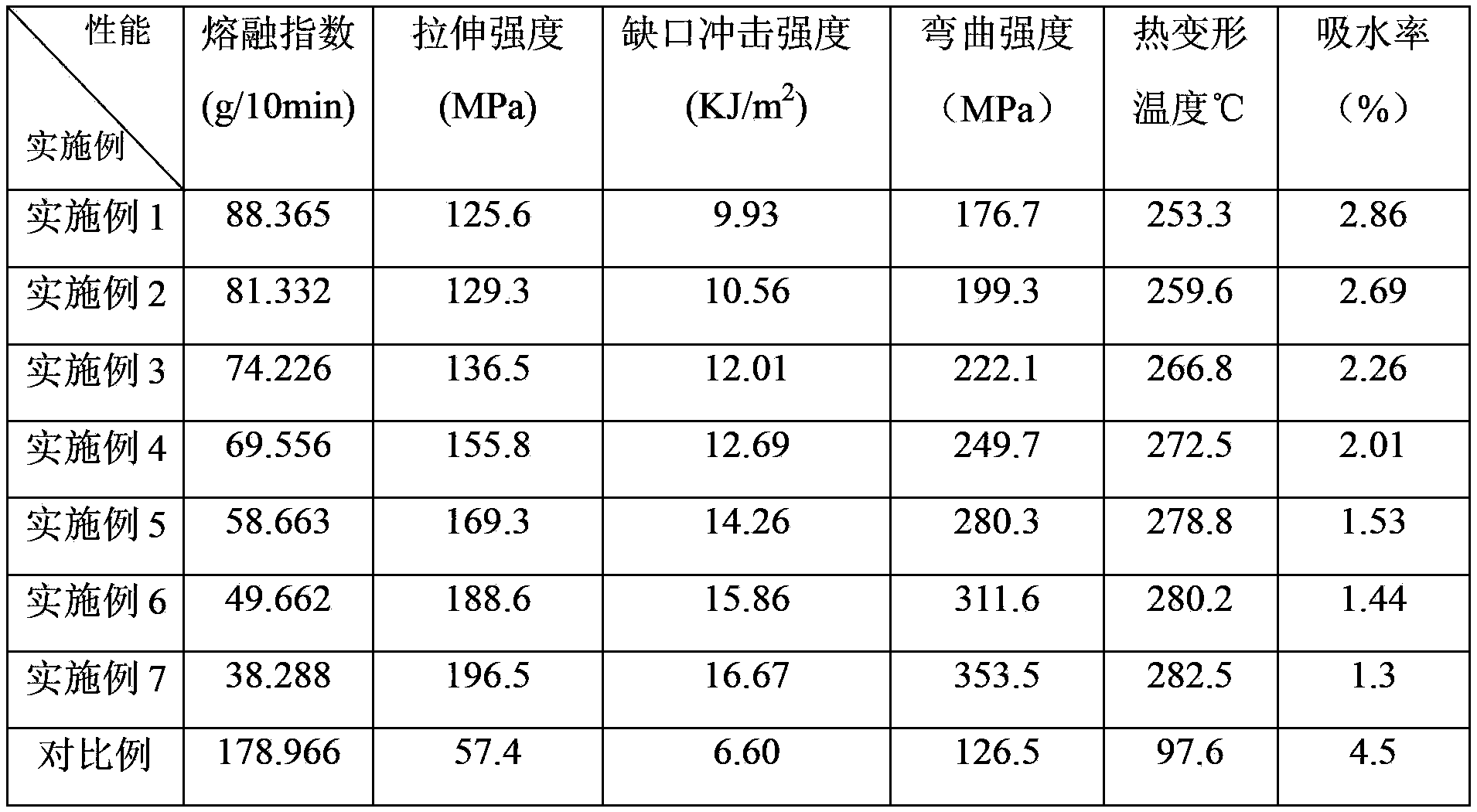

Examples

Embodiment 1

[0044] Provide an alkali-free short glass fiber reinforced nylon material, which is composed of the following components by weight ratio: nylon resin 610T: 70 parts, alkali-free short glass fiber (0.5cm in length): 20 parts, lubricant (ethylene acrylic acid copolymer A-C540A): 3 parts, antioxidant (antioxidant 1098:antioxidant 168 compound = 1:1): 7 parts, the total processing weight is 4kg.

[0045] (1) Dry the nylon resin at 90°C for 10 hours to fully remove the moisture,

[0046] (2) Then fully mix the nylon, antioxidant, lubricant and other components;

[0047] (3) Pour into the hopper of the extruder, and at the same time add the treated short alkali-free glass fiber to the side feeding port;

[0048] (4) Start the extruder and turn on the vacuum pump to extrude and granulate through the twin-screw extruder. The length-to-diameter ratio of the extruder screw is 40, and the extrusion temperature from zone 1 to the machine head is 295°C, 305°C, 315°C, 325°C, 330°C, 335°C,...

Embodiment 2

[0051] Provide an alkali-free short glass fiber reinforced nylon material, which is composed of the following components by weight ratio: nylon resin 66T: 65 parts, alkali-free short glass fiber (0.7cm in length): 25 parts, lubricant (ethylene acrylic acid copolymer A-C540A): 6 parts, antioxidant (antioxidant 1098:antioxidant 168 compound = 1:1): 4 parts, the total processing weight is 4kg.

[0052] (1) Dry the nylon resin at 95°C for 9 hours to fully remove the moisture,

[0053] (2) Then fully mix the nylon, antioxidant, lubricant and other components;

[0054] (3) Pour into the hopper of the extruder, and at the same time add the treated short alkali-free glass fiber to the side feeding port;

[0055](4) Start the extruder and turn on the vacuum pump to extrude and granulate through the twin-screw extruder. The length-to-diameter ratio of the extruder screw is 35, and the extrusion temperature from zone 1 to the machine head is 310°C, 320°C, 325°C, 335°C, 330°C, 335°C, 33...

Embodiment 3

[0058] Provide an alkali-free short glass fiber reinforced nylon material, which is composed of the following components by weight ratio: nylon resin 66: 60 parts, alkali-free short glass fiber (1.2cm in length): 30 parts, lubricant (ethylene acrylic acid copolymer A-C540A): 5 parts, antioxidant (antioxidant 1098:antioxidant 168 compound = 1:1): 5 parts, the total processing weight is 4kg.

[0059] (1) Dry the nylon resin at 100°C for 8 hours to fully remove the moisture,

[0060] (2) Then fully mix the nylon, antioxidant, lubricant and other components;

[0061] (3) Pour into the hopper of the extruder, and at the same time add the treated short alkali-free glass fiber to the side feeding port;

[0062] (4) Start the extruder, turn on the vacuum pump, extrude and granulate through the twin-screw extruder, the length-to-diameter ratio of the extruder screw is 50, and the extrusion temperature from zone 1 to the machine head is 300°C, 310°C, 320°C, 330°C, 335°C, 340°C, 345°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com