A coal-fired power plant sludge blending system and its intelligent supply method

A coal-fired power plant, sludge technology, applied in the direction of combustion method, fuel supply adjustment, combustion type, etc., can solve the problem of exceeding the upper limit of treatment, and achieve accurate and controllable sludge supply, high reliability, high efficiency and fast feedback control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

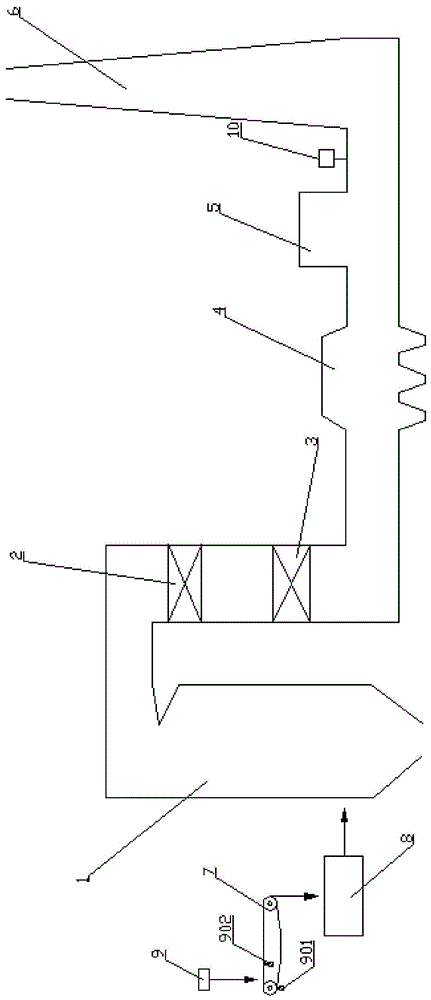

[0025] Such as figure 1 As shown, the coal-fired power plant sludge blending system of the present invention includes a pulverizing system, a coal feeder conveyor belt 7 for transporting raw coal, a screw feeder 9 for transporting sludge, a boiler furnace 1, and a chimney 6 And the flue connected between the boiler furnace 1 and the chimney 6. The outlet of the screw feeder 9 is set above the conveyor belt 7 of the coal feeder, and the conveyor belt 7 of the coal feeder puts the raw coal together with the sludge output by the screw feeder 9 into the pulverizing system, and the pulverizing system will Sludge and raw coal are pulverized into fuel powder and then blown into the boiler furnace 1 for combustion; the flue gas generated in the boiler furnace 1 passes through the flue and then is discharged from the chimney 6, in which an economizer 2, an air preheater 3 and A pollutant control device for removing flue gas pollutants, the pollutant control device includes an electros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com