Preparation method of vanadium dioxide based multifunctional composite film

A technology of vanadium dioxide and composite film, applied in coating, surface pretreatment, device for coating liquid on surface, etc., can solve problems such as difficulty in process and film quality control, and achieve increased applicability and optimized optical performance , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034]The invention provides a convenient and effective preparation method for a single-layer vanadium dioxide-based composite membrane with a self-cleaning effect, which can obtain a high-quality single-layer vanadium dioxide-based composite membrane with a self-cleaning effect. The invention discloses an intelligent dimming multifunctional composite film based on a vanadium dioxide material and a preparation method thereof. In the present invention, by compounding other materials with photocatalytic properties and vanadium dioxide materials, the obtained single-layer composite film has thermal dimming performance and self-cleaning effect, which greatly increases the vanadium dioxide smart film. applicability. The preparation method disclosed by the invention has simple process and strong controllability, and can be widely used in the preparation of vanadium dioxide smart films on inorganic or high-temperature-resistant organic substrates, and at the same time, components can...

Embodiment 1

[0054] Example 1 Silane coupling agent modified vanadium dioxide-zinc oxide composite film

[0055] Take zinc acetate and ethanolamine at a molar ratio of 1:1, add them to ethylene glycol methyl ether, adjust the concentration to 0.35M, and age for more than 3 days;

[0056] Add 0.1g of vanadium dioxide nanopowder into 20ml of zinc oxide sol, ultrasonically and magnetically stir for 30 minutes, then add silane coupling agent KH550, the mass ratio of coupling agent to vanadium dioxide is 0.1:1, after adding the coupling agent, use sand Grind for 12 hours to obtain a uniformly dispersed composite film sol;

[0057] The composite sol was applied on the homogenizer at a speed of 800rad / min for 30s, and the obtained composite film was dried in an oven at 80°C for one day;

[0058] The dried composite film is heated up to 500°C at 10°C / min in a tube furnace under a nitrogen atmosphere, kept for 30 minutes and then cooled naturally;

[0059] The obtained composite film has a visibl...

Embodiment 2

[0060] Example 2 Titanate Modified Vanadium Dioxide-Titanium Dioxide Composite Membrane

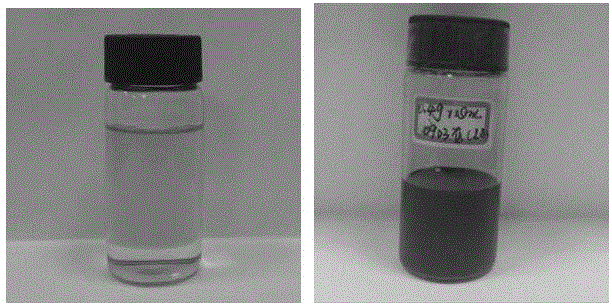

[0061] Take tetrabutyl titanate: 24ml, concentrated hydrochloric acid: 0.920ml, water: 0.590ml, add in 150ml dehydrated alcohol successively, after mixing well, obtain titanium dioxide sol (such as figure 1 (shown on the left side); take 20ml, add 0.2g vanadium dioxide nanopowder, and ultrasonically stir at 60°C for more than 3 days to obtain a uniformly dispersed composite sol (such as figure 1 shown on the right);

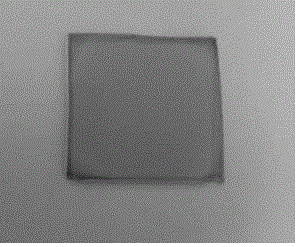

[0062] The composite sol adopts the pulling method, and the film is pulled at a pulling speed of 10mm / min. The obtained sample was dried in an oven at 80°C for one day after wiping off the film on one side with absolute ethanol (such as figure 2 shown);

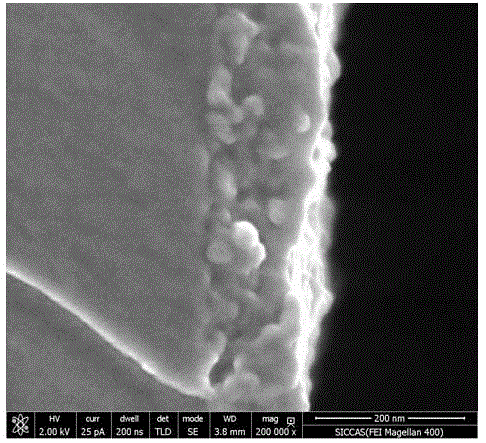

[0063] The dried composite membrane was heated up to 300°C at 10°C / min in a nitrogen atmosphere in a tube furnace, and kept for one day to obtain a composite membrane with self-cleaning effect. from Figure 5 It can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com