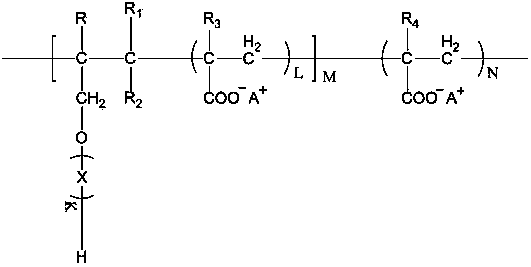

Polymer water reducing agent used for ceramic machining and synthetic method thereof

A technology of ceramic processing and synthesis method, applied in the field of ceramic processing aids, can solve the problem of low overall research level of ceramic water reducer, and achieve the effects of increasing compactness, improving grinding efficiency, improving strength and forming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

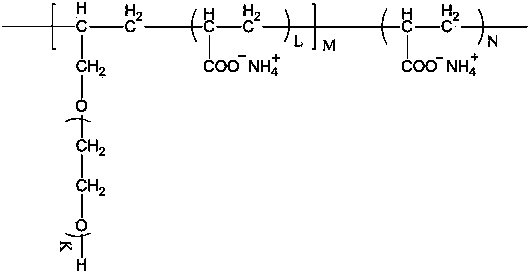

example 1

[0038] Add 145kg of allyl alcohol polyoxyethylene ether with a molecular weight of 2000 and 120kg of water into the reactor, heat to 30°C and stir to completely dissolve the allyl alcohol polyoxyethylene ether, then add 1.2kg of hydrogen peroxide (mass concentration 35%).

[0039] Add 18kg of acrylic acid and 20kg of deionized water into No. 1 high-level tank, add 0.2kg of ascorbic acid, 1.0kg of isopropanol and 38kg of deionized water into No. 2 high-level tank, and then slowly add the solutions in the two high-level tanks to the reaction kettle at the same time. The liquid in the No. 1 high-level tank is added in about 3 hours, and the liquid in the No. 2 high-level tank is added in about 3.5 hours. Add 80kg of acrylic acid to No. 3 head tank, add 0.5 kg of ascorbic acid and 80 kg of deionized water to No. 4 head tank. After the liquid was added to the No. 2 head tank, the constant temperature stirring reaction was continued for 1.0 hour to obtain an intermediate polymer. T...

example 2

[0043] Add 150kg of allyl alcohol polyoxyethylene polyoxypropylene copolyether with a molecular weight of 2400 and 120kg of water into the reactor, heat to 30°C and stir to completely dissolve the allyl alcohol polyoxyethylene ether, then add hydrogen peroxide (mass concentration 35% ) 1.0kg.

[0044] Add 15kg of acrylic acid and 20kg of deionized water to the No. 1 high-level tank, add 0.2kg of ascorbic acid, 1.0kg of isopropanol and 38kg of deionized water to the No. 2 high-level tank, and then slowly add the solutions in the two high-level tanks to the reaction kettle at the same time. The liquid in the No. 1 high-level tank is added in about 3 hours, and the liquid in the No. 2 high-level tank is added in about 3.5 hours. Add 100kg of acrylic acid to No. 3 head tank, add 0.4 kg of ascorbic acid and 100 kg of deionized water to No. 4 head tank. After the liquid was added to the No. 2 head tank, the constant temperature stirring reaction was continued for 1.0 hour to obtain...

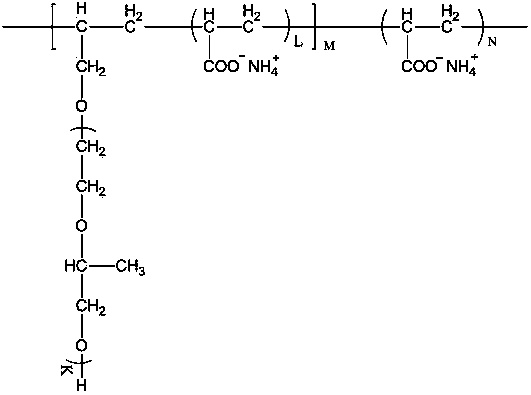

example 3

[0048] Add 180kg of isopentenyl alcohol polyoxyethylene polyoxypropylene copolyether with a molecular weight of 2400 and 120kg of water into the reactor, heat to 30°C and stir to completely dissolve the allyl alcohol polyoxyethylene ether, then add hydrogen peroxide (mass concentration 35 %) 1.2kg.

[0049] Add 20kg of acrylic acid and 20kg of deionized water into No. 1 high-level tank, add 0.2kg of ascorbic acid, 0.5kg of thioglycolic acid and 38kg of deionized water into No. 2 high-level tank, and then slowly add the solutions in the two high-level tanks to the reactor at the same time, and control 1 The liquid in the No. 2 high tank is added in about 3 hours, and the liquid in the No. 2 high tank is added in about 3.5 hours. Add 100kg of acrylic acid to No. 3 head tank, add 0.5 kg of ascorbic acid and 100 kg of deionized water to No. 4 head tank. After the liquid was added to the No. 2 head tank, the constant temperature stirring reaction was continued for 1.0 hour to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com