Solid-liquid phase change heat exchange working medium for power generation by oceanic thermal energy and preparation method of working medium

A technology of solid-liquid phase transition and temperature difference energy, which is applied in the fields of ocean energy power generation, heat exchange materials, chemical instruments and methods, etc. Efficiency and stable dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

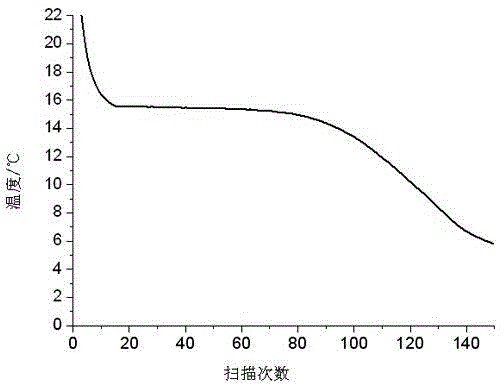

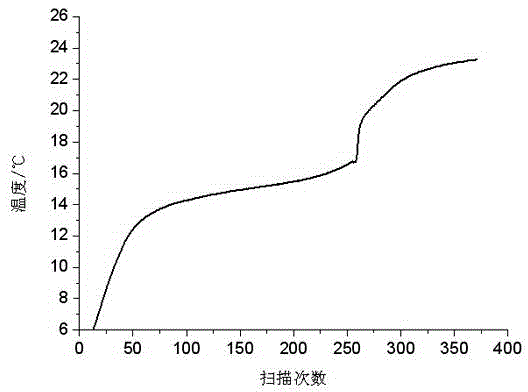

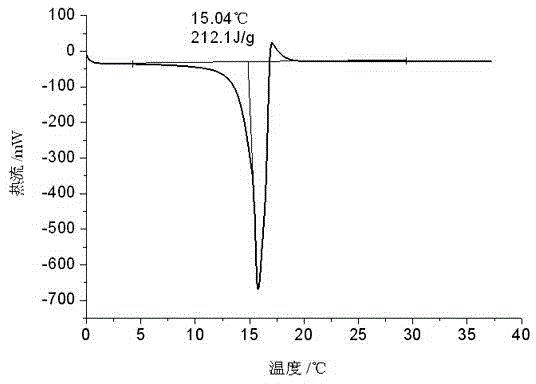

Image

Examples

Embodiment 1

[0039] 1. Composition of solid-liquid phase change heat exchange working fluid materials

[0040] Ternary composite material mixture: n-pentadecane, n-hexadecane, n-heptadecane mass ratio 0.8:6:3.2, modifier: expanded graphite with 0.1% of the total mass of the ternary composite material mixture, dispersant: ternary Sodium dodecylbenzene sulfonate of 0.1% of the total mass of the composite material mixture;

[0041] 2. Preparation

[0042] (1) Mix C15:C16:C17 n-alkanes according to the mass ratio to form a ternary composite material mixture;

[0043] (2) Preparation of expanded graphite by high temperature expansion method in muffle furnace

[0044] Use a vacuum drying oven to dry the expandable graphite for 1 hour, take a small amount of dried expandable graphite powder and place it in a ceramic crucible, and then place it in a muffle furnace at a temperature of 600°C to heat and expand for 5 minutes to obtain expanded graphite.

[0045](3) Add expanded graphite and sodium...

Embodiment 2

[0047] 1. Composition of solid-liquid phase change heat exchange working fluid materials

[0048] Ternary composite material mixture: n-pentadecane, n-hexadecane, n-heptadecane mass ratio 0.6:6:3.4, modifier: expanded graphite with 0.2% of the total mass of the ternary composite material mixture, dispersant: ternary 0.2% sodium dodecylbenzenesulfonate of the total mass of the composite material mixture;

[0049] 2. Preparation

[0050] (1) Mix C15:C16:C17 n-alkanes according to the mass ratio to form a ternary composite material mixture;

[0051] (2) Preparation of expanded graphite by microwave high-temperature expansion method

[0052] Due to the conductivity of graphite, graphite will generate eddy current under the action of microwave, which will produce a severe heating effect, causing graphite to expand rapidly, thus forming expanded graphite;

[0053] (3) Add expanded graphite and sodium dodecylbenzenesulfonate in sequence to the ternary composite material mixture, a...

Embodiment 3

[0055] 1. Composition of solid-liquid phase change heat exchange working fluid materials

[0056] Ternary composite material mixture: n-pentadecane, n-hexadecane, n-heptadecane mass ratio 0.6:7:2.4, modifier: expanded graphite with 0.5% of the total mass of the ternary composite material mixture, dispersant: ternary 0.4% sodium dodecylbenzenesulfonate of the total mass of the composite material mixture;

[0057] 2. Preparation

[0058] (1) Mix C15:C16:C17 n-alkanes according to the mass ratio to form a ternary composite material mixture;

[0059] (2) Preparation of expanded graphite by high temperature expansion method in muffle furnace

[0060] Use a vacuum drying oven to dry the expandable graphite for 1 hour, take a small amount of dried expandable graphite powder and place it in a ceramic crucible, and then place it in a muffle furnace at a temperature of 600°C to heat and expand for 5 minutes to obtain expanded graphite;

[0061] (3) Expanded graphite and sodium dodecy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com