Surface plasmon polariton-enhanced photoelectric detector based on MIM (Metal Injection Molding) structure

A surface plasmon and photodetector technology, applied in the field of detection and sensing, can solve problems such as unfavorable integration and reduction of raw material costs, insufficient spectral response range of detectors, toxicity of photoelectric sensitive materials, etc., and achieves less consumables. , to stimulate the effect of high efficiency and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: The structural parameters of the present invention are obtained by solving the electromagnetic field and using finite element algorithm simulation and optimization. The specific light absorption characteristics of the structure will be given in the accompanying drawings.

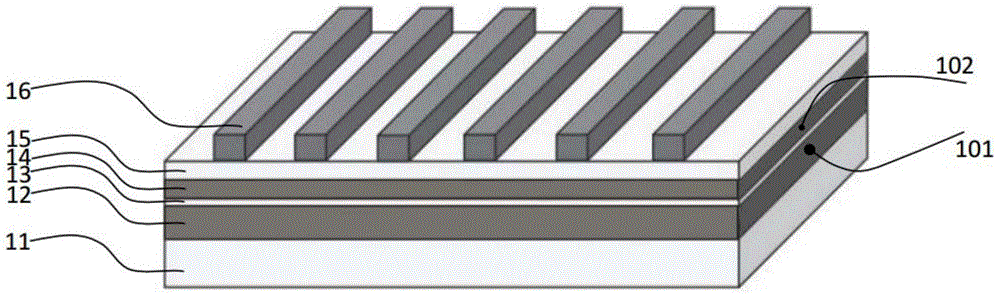

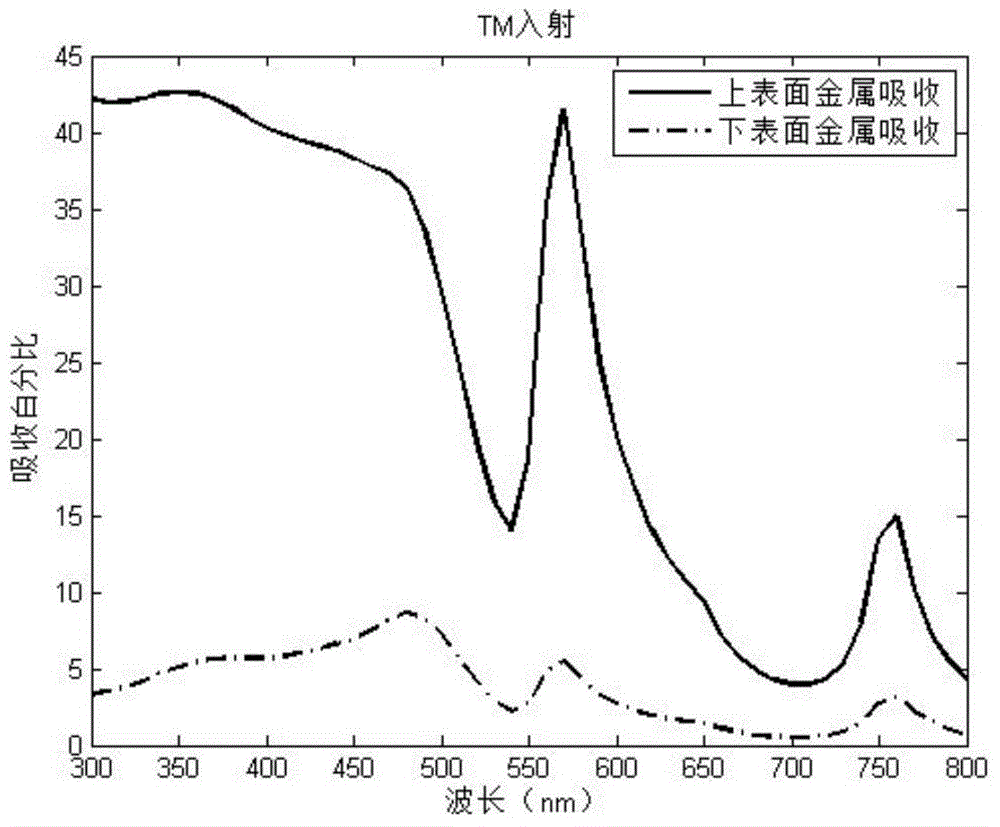

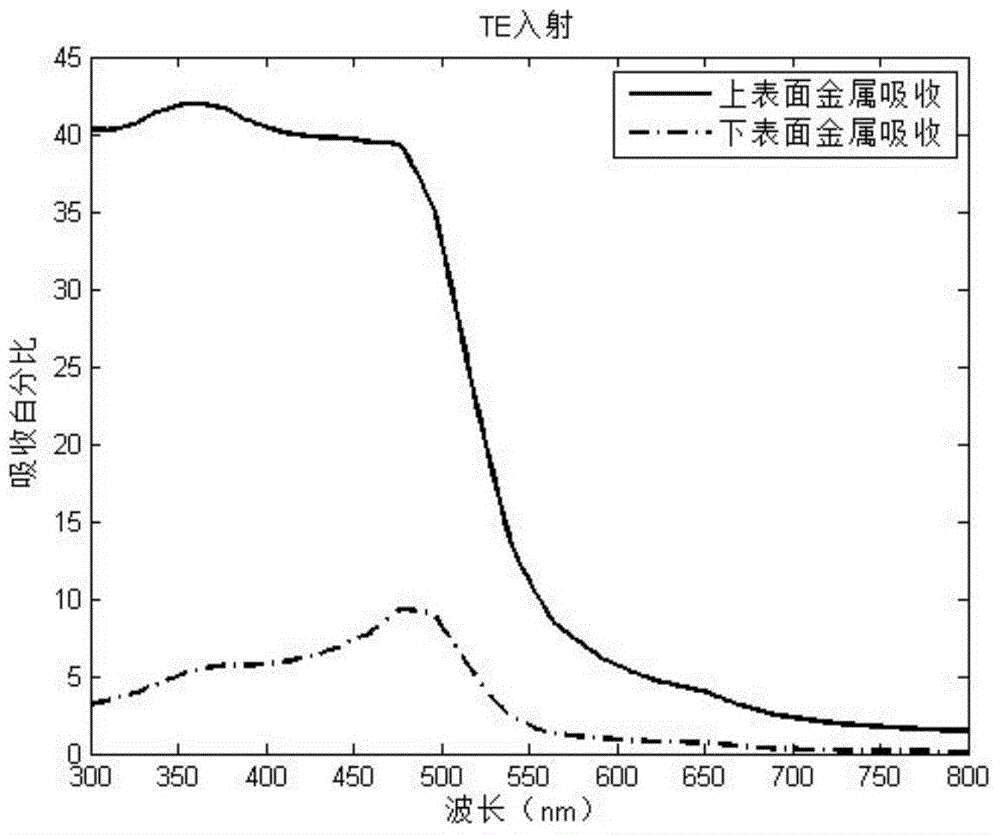

[0040] Combine figure 1 As shown, the surface plasmon-enhanced photodetector based on the MIM structure provided by this embodiment uses a substrate 11 (the material is quartz, the thickness is 1000 μm, and the thickness is generally thicker, taking practical operation as the starting point) , The lower metal film layer 12 (material is gold, thickness is 50nm), the lower dielectric spacer 13 (material is alumina, thickness is 3nm), upper metal film layer 14 (material is Gold, thickness 20nm), upper dielectric spacer 15 (material is silicon dioxide, thickness 30nm) and metal grating layer 16 (material is gold, thickness is 50nm, period is 500nm, duty cycle is 0.36), and includes The upper an...

Embodiment 2

[0051] Example 2: See the structure figure 1 It is the same as Embodiment 1, but the difference is that the period of the metal grating is changed from 500 nm in Embodiment 1 to 800 nm, that is, the duty cycle is still 0.3, and the thickness of the metal grating is 50 nm. Through the finite element method simulation, the response of the upper and lower metal film layers 14, 12 to the spectrum can be obtained. As attached Image 6 As shown, by adjusting the period, duty ratio, and thickness of the metal grating, the resonance wavelength of the surface plasmon is changed, which affects the difference in the response of the device to light in different spectral ranges. For this embodiment, from the attached Image 6 It can also be seen that at a wavelength of 1350 to 1550 nm, the upper and lower metal film layers 14, 12 have a large difference in light absorption, so this structure can be used to detect the subtle changes of incident photons in the above-mentioned wavelength range....

Embodiment 3

[0052] Example 3: See for its structure figure 1 It is the same as Embodiment 1, but the difference is that the period of the metal grating is changed from 500 nm in Embodiment 1 to 1000 nm, that is, the duty ratio is still 0.3, and the thickness of the metal grating is 50 nm. Through the finite element method simulation, the response of the upper and lower metal film layers 14, 12 to the spectrum can be obtained. As attached Figure 7 As shown, by adjusting the period, duty ratio, and thickness of the metal grating, the resonance wavelength of the surface plasmon is changed, which affects the difference in the response of the device to light in different spectral ranges. For this embodiment, from the attached Figure 7 It can be seen that at the wavelength of 1600 to 1900 nm, the upper and lower metal film layers 14, 12 have a relatively large difference in light absorption, so this structure can be used to detect the subtle changes of incident photons in the above wavelength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com