Ceramic cylindrical sputtering target and method for producing same

A technology of sputtering target material and manufacturing method, which is applied to manufacturing tools, sputtering coating, ceramic molding machines, etc., can solve the problem of increasing the number of arcs, and achieve the effect of less generation and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] The specific surface area measured by the BET method is 10m 2 / g of SnO 2 Powder and specific surface area measured by BET method is 10m 2 / g In 2 o 3 powder to make SnO 2 The amount becomes 1% by mass and is mixed in a tank with zirconia balls in a ball mill to prepare a ceramic raw material powder.

[0109] In this tank, as binder, add the polyvinyl alcohol (polymerization degree: 280, alkalization degree is mol percent 68%) for ceramic raw material powder by mass percent, as dispersant, add mass percent for ceramic raw material powder 0.3% of ammonium polycarboxylate, and as a dispersion medium, 15% by mass of water was added to the ceramic raw material powder and mixed in a ball mill to prepare a slurry. The ratio of the amount of ceramic raw material powder to the total amount of organic additives (the total amount of polyvinyl alcohol and ammonium polycarboxylate) was 0.4% by mass.

[0110] This slurry was supplied to a spray drying apparatus, and spray dryi...

Embodiment 2~20

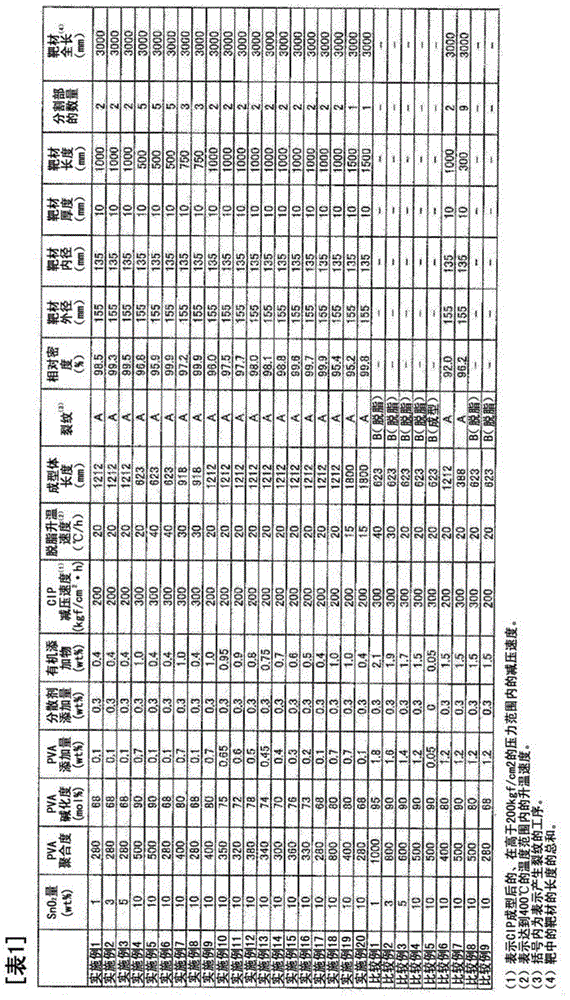

[0117] [Examples 2-20, Comparative Examples 1-9]

[0118] Examples 2-20 and Comparative Examples 1-9 were implemented on the following conditions.

[0119] SnO in the ceramic raw material powder 2 The content of powder, the degree of polymerization of polyvinyl alcohol and the degree of alkalization, the addition amount of polyvinyl alcohol, and the addition amount of ammonium polycarboxylate are set as the conditions shown in Table 1, and the same method as in Example 1 is used except that way to prepare particles.

[0120] The pellets were subjected to CIP molding to produce cylindrical molded bodies having the lengths shown in Table 1. In CIP molding, Examples 2, 3, 9 to 18, and Comparative Example 6 use the same polyurethane rubber mold as in Example 1, while other Examples and Comparative Examples use the same polyurethane rubber mold as in Example 1. The rubber molds have the same core and inner diameter, and are urethane rubber molds having the lengths to obtain mold...

Embodiment 21

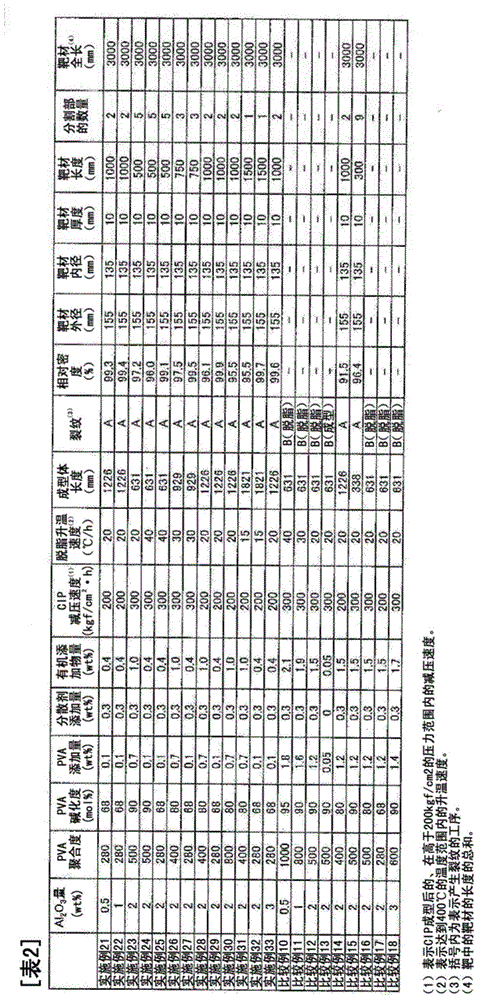

[0127] The specific surface area measured by the BET method is 5m 2 / g Al 2 o 3 Powder and specific surface area measured by BET method is 10m 2 / g ZnO powder to make Al 2 o 3 content of 0.5% by mass, and mixed in a tank with zirconia balls in a ball mill to prepare ceramic raw material powder.

[0128] Except having used this ceramic raw material powder, it carried out similarly to Example 1, and produced the pellet.

[0129]Under the same conditions as in Example 1, a cylindrical core (mandrel) with an inner diameter of 213 mm (thickness of 10 mm) and a length of 1233 mm was used with a top and bottom sealable cap and a cylindrical core (mandrel) with an outer diameter of 167 mm. The pellets were subjected to CIP molding to produce cylindrical moldings having the lengths shown in Table 2.

[0130] This molded body was degreased under the same conditions as in Example 1.

[0131] The degreased molded body was sintered under the same conditions as in Example 1 to produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com