Oyster meat nutrition powder and preparation method thereof

A technology of oyster meat and nutritional powder is applied in the directions of food preparation, food ion-exchange membrane method, function of food ingredients, etc., which can solve the problems of poor taste, rough texture of oyster sauce, affecting the development of oyster breeding industry, etc., and achieves convenient consumption. , product quality is stable, good rehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

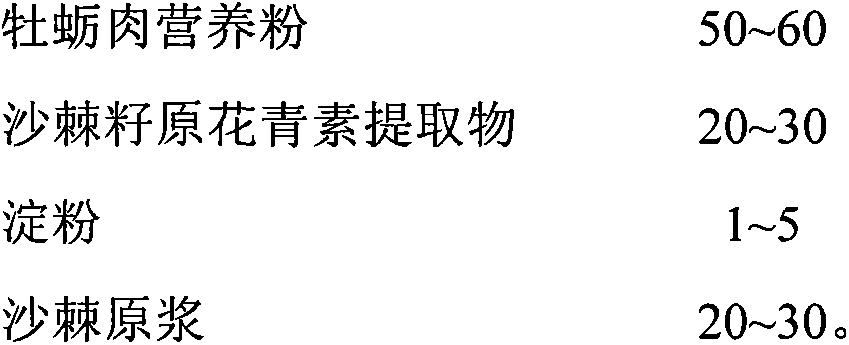

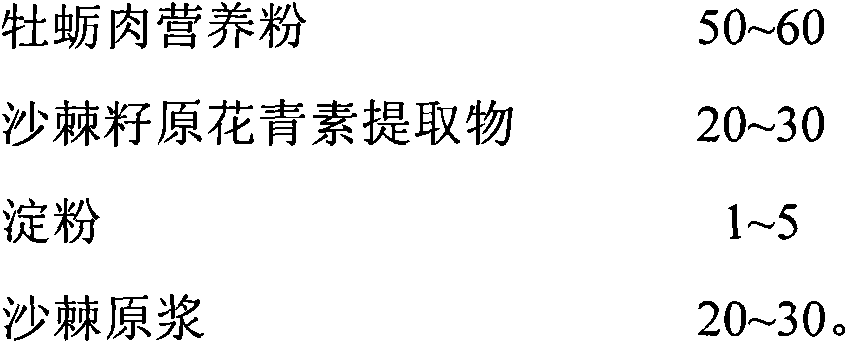

[0031] An oyster meat nutritional powder, which is obtained by the following preparation method, and the preparation method includes the following steps:

[0032] (1) Raw material pretreatment: Wash the oyster meat, remove the internal organs, homogenize it with a high-speed tissue masher, and prepare an oyster homogenate in a mass ratio of 1:1 to 1:3 based on the raw materials and water;

[0033] (2) High-pressure homogenization: the oyster homogenate obtained in step (1) is homogenized at a pressure of 30 MPa to 40 Mpa, so that the oyster raw material becomes uniform and fine particles to obtain an oyster homogenized liquid;

[0034] (3) Enzymatic hydrolysis assisted by ultrasound to prepare enzymatic hydrolysate: the oyster homogenized solution obtained in step (2) is enzymatically hydrolyzed with an enzymatic solution, pH 8.6 to 9.2, enzymatic hydrolysis temperature 38°C to 42°C, enzymatic hydrolysis Time 2h~4h; at the same time, ultrasonic treatment is carried out under the cond...

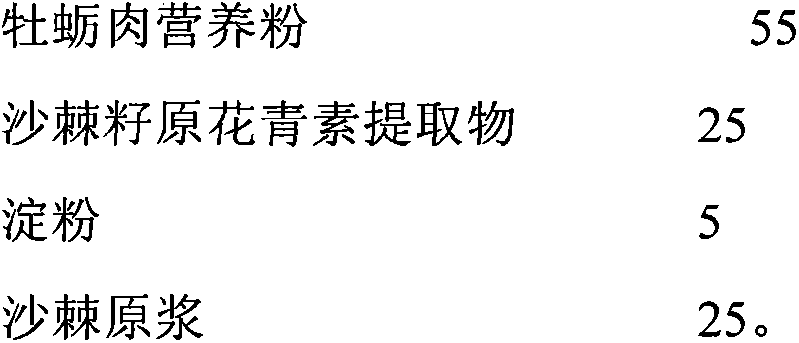

Embodiment 2

[0049] This example is an optimized solution based on Example 1, and provides a method for preparing oyster meat nutritional powder. For the same parts in this embodiment as Embodiment 1, please refer to the content disclosed in Embodiment 1 for understanding. The content disclosed in Embodiment 1 should also be included as the content of this embodiment, and the description will not be repeated here.

[0050] The method for preparing oyster meat nutritional powder provided in this embodiment includes the following steps:

[0051] (1) Raw material pretreatment: Wash the fresh oyster meat, remove the internal organs, homogenize it with a high-speed tissue masher, and prepare an oyster homogenate according to the ratio of raw material to water at 1:1;

[0052] (2) High-pressure homogenization: homogenize the oyster homogenate obtained in step (1) at a pressure of 30 MPa, so that the oyster raw material becomes uniform and fine particles, which are easy to hydrolyze and increase the deg...

Embodiment 3

[0059] This example is an optimized solution based on Example 1, and provides a method for preparing oyster meat nutritional powder. For the same parts in this embodiment as Embodiment 1, please refer to the content disclosed in Embodiment 1 for understanding. The content disclosed in Embodiment 1 should also be included as the content of this embodiment, and the description will not be repeated here.

[0060] The oyster raw material used in this embodiment is frozen oyster meat, which includes the following steps:

[0061] (1) Raw material pretreatment: The frozen oyster meat stream is hydrolyzed, washed, and the internal organs are removed, homogenized by a high-speed tissue masher, and prepared into an oyster homogenate according to the ratio of raw materials to water at a mass ratio of 1:2;

[0062] (2) High-pressure homogenization: the oyster homogenate obtained in step (1) is homogenized at a pressure of 35 MPa, so that the oyster raw material becomes uniform and fine particles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com