Preparation method for large-diameter and super-long nano carbon tube

A technology of carbon nanotubes and large diameters, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., which can solve the problems of time-consuming, cumbersome steps, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Add 1g of glucosamine hydrochloride and 100ml of deionized water into a 250ml beaker, stir to dissolve, then add 0.48g of transition metal salt nickel nitrate, and stir until a uniform solution. Add 20g melamine then, dissolve in the above-mentioned glucosamine hydrochloride solution. Heat and stir until the deionized water is completely volatilized to obtain a solid mixture, which is calcined in a nitrogen furnace through a two-stage heating program (600°C for 1h and 1000°C for 1h), and treated with HCl to obtain nano-carbon materials.

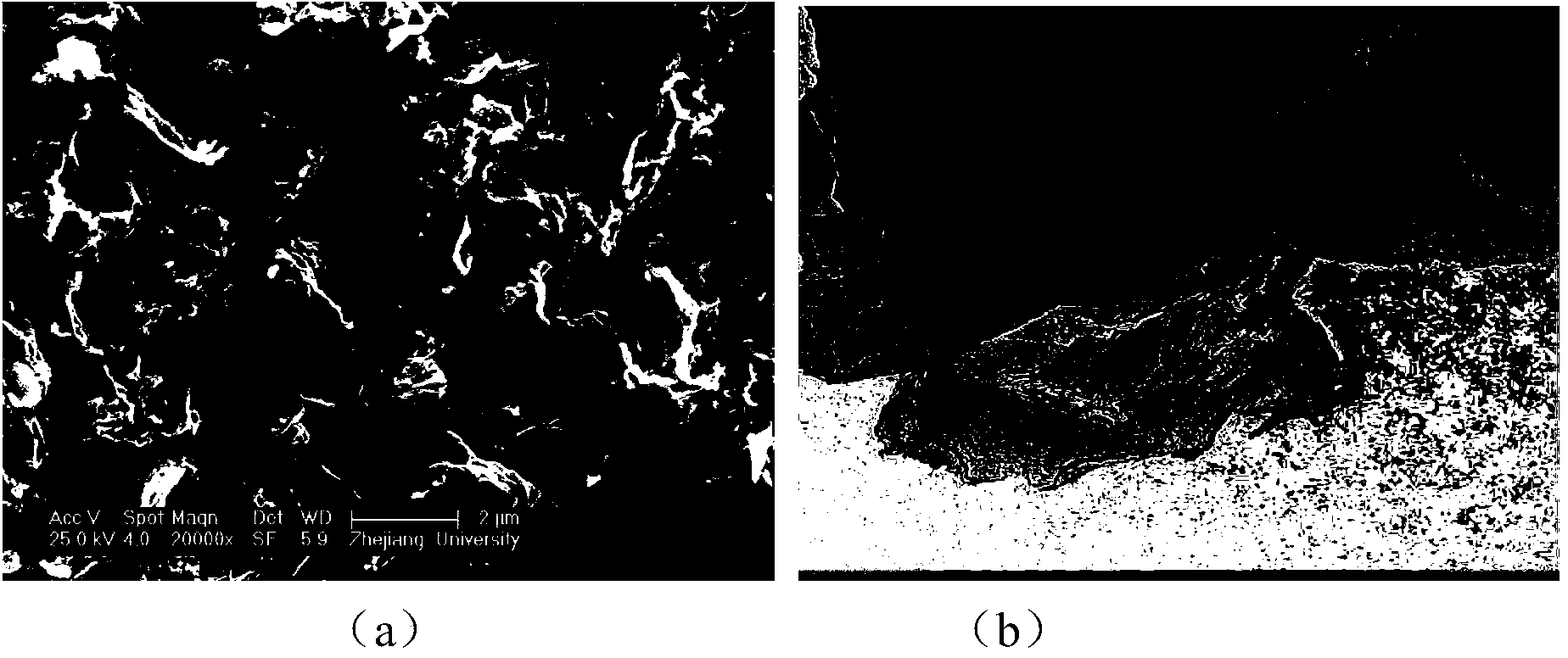

[0054] The scanning electron microscope picture of the carbon nanomaterial prepared in this embodiment is shown in figure 2 , as can be seen from the electron microscope images, the material prepared under this condition has a sheet-like structure in a large range, and there are obvious protrusions on the surface of the sheet, which are just formed short carbon tubes.

Embodiment 2

[0056] Add 1g of glucosamine hydrochloride and 150ml of deionized water into a 250ml beaker, stir to dissolve, then add 0.95g of transition metal salt nickel nitrate, and stir until a uniform solution. Add 20g melamine then, dissolve in the above-mentioned glucosamine hydrochloride solution. Heat and stir until the deionized water is completely volatilized to obtain a solid mixture, which is calcined in a nitrogen furnace through a two-stage heating program (600°C for 1h and 1000°C for 1h), and treated with HCl to obtain nano-carbon materials.

[0057] The scanning electron microscope picture of the carbon nanomaterial prepared in this embodiment is shown in image 3 , as can be seen from the electron microscope image, the material prepared by this method is the coexistence of tubular structure and sheet structure, and there are a large number of long tubes on the sheet layer. Compared with Example 2, the proportion of carbon tubes in the material prepared under this condition...

Embodiment 3

[0059] Add 1g of glucosamine hydrochloride and 200ml of deionized water into a 250ml beaker, stir to dissolve, then add 1.1g of transition metal salt nickel nitrate, and stir until a uniform solution. Add 20g melamine then, dissolve in the above-mentioned glucosamine hydrochloride solution. Heat and stir until the deionized water is completely volatilized to obtain a solid mixture. After the mixture is calcined in a nitrogen furnace through a two-stage heating program (600°C for 1h, 1000°C for 1h), HCl treatment and purification can obtain a large diameter, ultra-long nanometer carbon tube.

[0060] The scanning electron micrograph of carbon nanotubes prepared in this embodiment is shown in Figure 4 , from the results of electron microscopy, the inner diameter of carbon tubes is within 50-100nm, and the length is in the order of microns. It can be seen from the electron microscope images that the materials prepared by this method form a tubular structure in a large range.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com