Modified acrylonitrile-butadiene-styrene (ABS) resin with low glossiness and high performance

An ABS resin, low gloss technology, applied in the field of resin, can solve the problem of ABS resin application is slightly insufficient, difficult to maintain rigidity and hardness, etc., to achieve significant thermal oxidation resistance, improve thermal oxidation resistance, and enhance flexural strength. and the effect of flexural modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

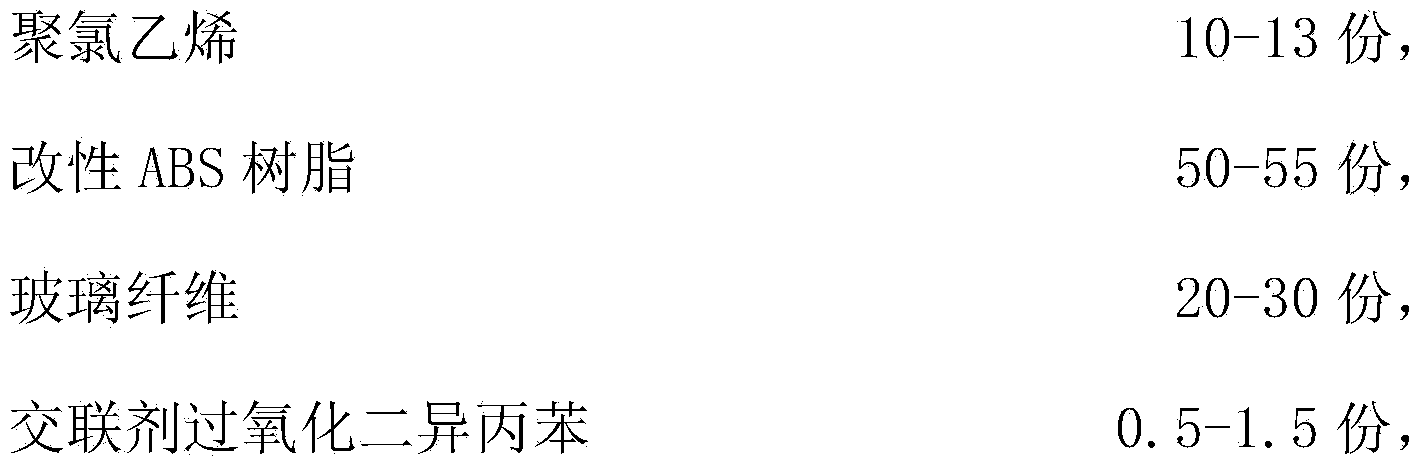

[0016] A kind of low-gloss high-performance modified ABS resin proposed by the present invention, its raw material comprises by weight:

[0017]

[0018]

[0019] Wherein, the modified ABS resin is obtained by grafting ABS resin with N-phenylmaleimide, and the single filament diameter of the glass fiber is 15 microns.

Embodiment 2

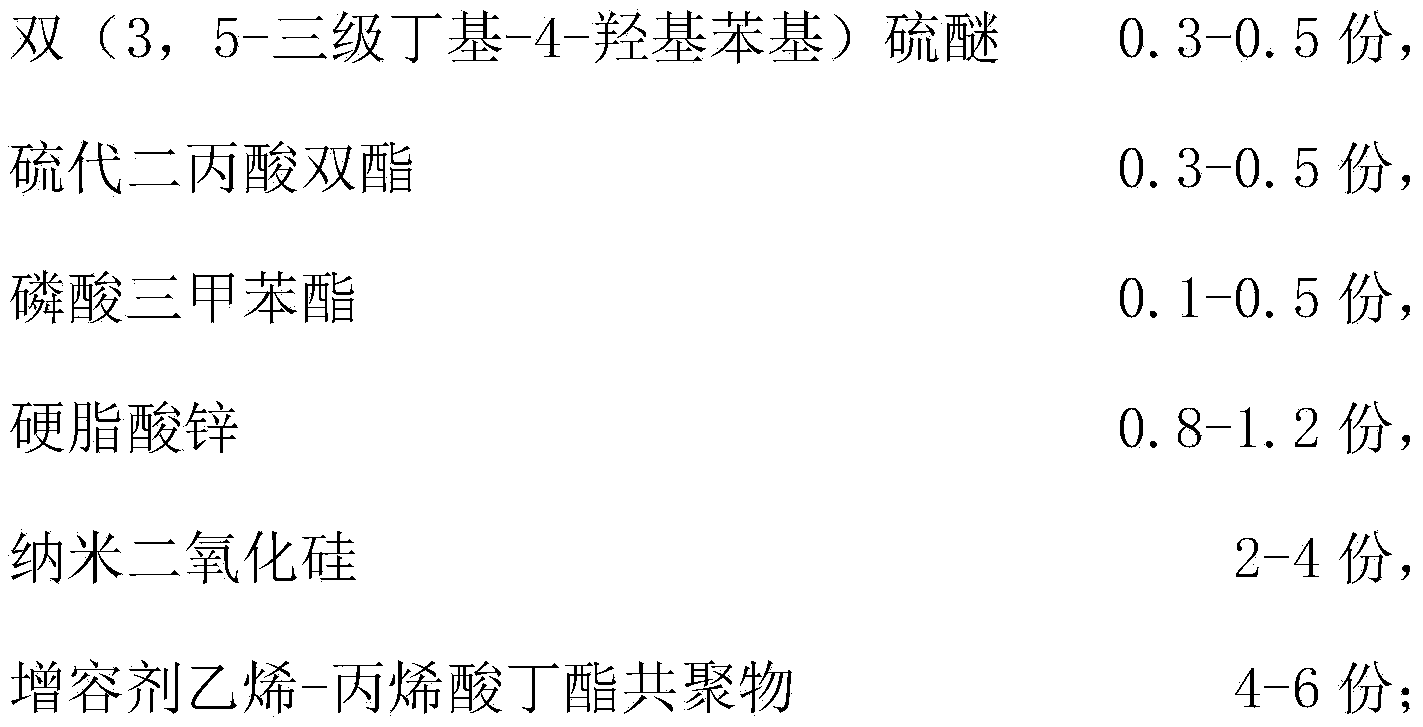

[0021] A kind of low-gloss high-performance modified ABS resin proposed by the present invention, its raw material comprises by weight:

[0022]

[0023] Wherein, the modified ABS resin is obtained by grafting ABS resin with N-phenylmaleimide, and the monofilament diameter of the glass fiber is 13 microns.

Embodiment 3

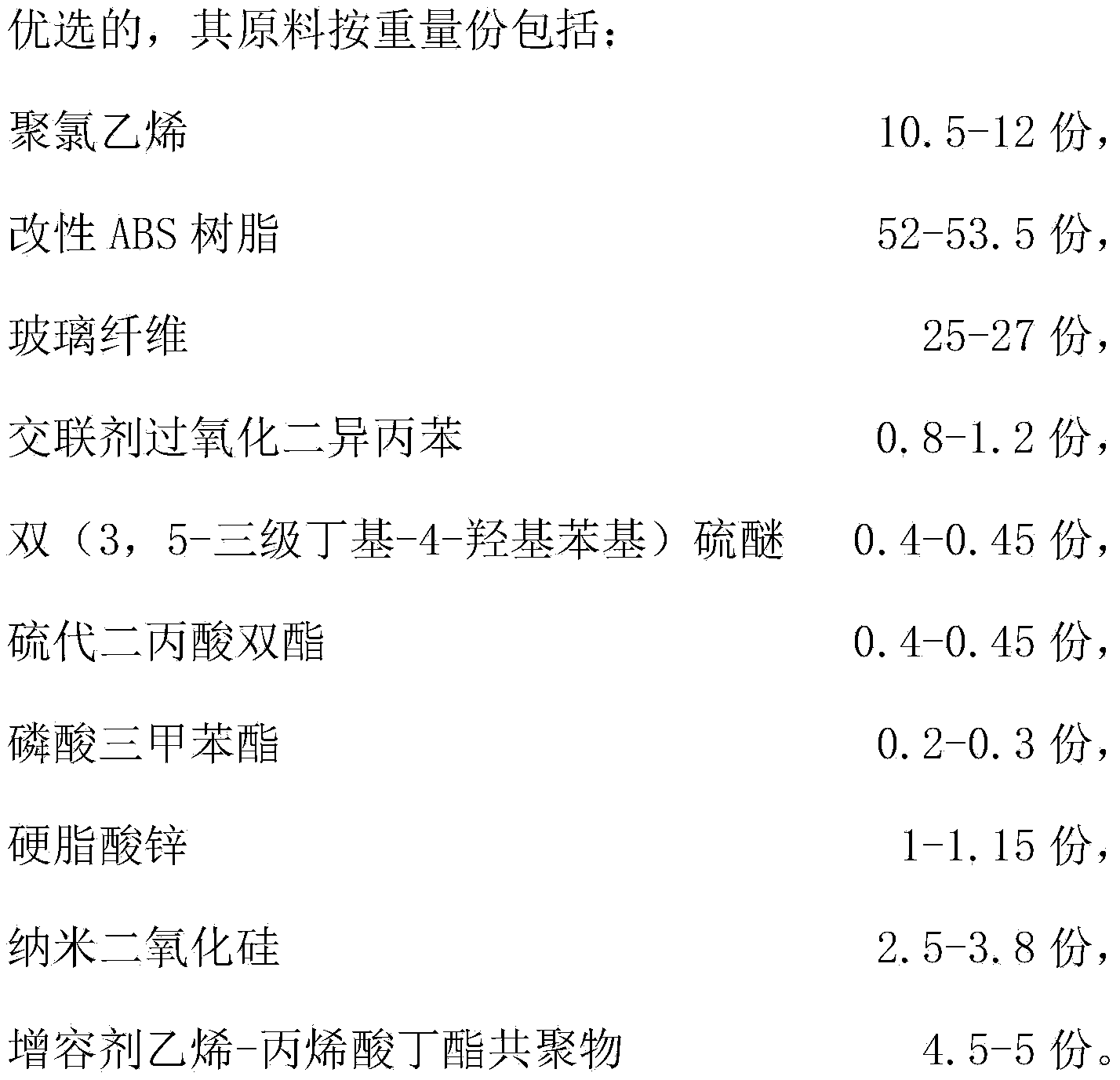

[0025] A kind of low-gloss high-performance modified ABS resin proposed by the present invention, its raw material comprises by weight:

[0026]

[0027]

[0028] Among them, the modified ABS resin is obtained by grafting ABS resin with N-phenylmaleimide, and the monofilament diameter of the glass fiber is 10 microns; 15% for 50-70nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com