A high-efficiency darkening agent and its preparation and finishing application method

An application method and a technology of a deepening agent, which are applied in the field of high-efficiency deepening agent and its preparation and finishing application, can solve the problems of low deepening rate, no explanation of the deepening rate, and insufficient application effect, and achieve deep deepening. The effect is improved, the apparent dark color effect of the fabric is improved, and the color difference is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

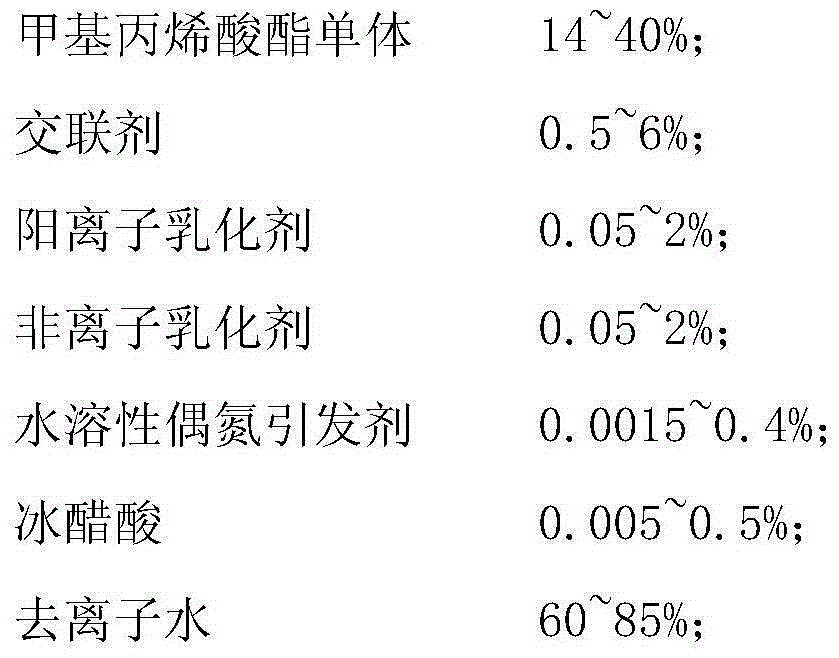

Embodiment 1

[0050] 1) Preparation of pre-emulsion: 20g of methyl methacrylate and 1g of ethylene glycol diacrylate are mutually dissolved as the oil phase; 1g of cationic emulsifier 1831 and non-ionic emulsifier are added to O-15 (the ratio of the two is 2:1), 0.2g glacial acetic acid, dissolved in 31g deionized water as the water phase. Mix the water phase and the oil phase, and stir at 1500 rpm for 35 minutes at room temperature to obtain a pre-emulsion;

[0051] 2) Prepare the primer: add 0.35g of 1831 and Pingping O-15 (the ratio of the two is 1:1), 0.06g of azobisisobuimidazoline hydrochloride and 47g of deionized water, and stir to dissolve at room temperature Evenly. Put all the primers into a four-necked flask connected with a stirrer, thermometer, condenser and nitrogen tube;

[0052] 3) Polymerization reaction: Fill the flask with primer for 20 minutes with nitrogen to remove oxygen, while stirring, the water bath is heated up, and the temperature in the flask is stabilized at 75 ℃...

Embodiment 2

[0054] Step 1) According to Example 1, the crosslinking agent used is changed to 2g ethylene glycol dimethacrylate, and the deionized water is 29.8g;

[0055] Steps 2) and 3) are the same as in Example 1. The measured solid content of the deepening agent is 21.9%, and the monomer conversion rate is 99.6%.

Embodiment 3

[0057] 1) Preparation of pre-emulsion: 25g methyl methacrylate and 2.5g ethylene glycol dimethacrylate are mutually dissolved as the oil phase; 1.1g cationic emulsifier 1227 and nonionic emulsifier are added to O-15 (two The dosage ratio is 2:1), 0.25g glacial acetic acid, dissolved in 28g deionized water as the water phase. Mix the water phase and the oil phase, and stir at 1500 rpm for 35 minutes at room temperature to obtain a pre-emulsion;

[0058] 2) Prepare the primer: add 0.5g 1227 and flattened O-15 (the ratio of the two is 1:1), 0.09g azobisisobuimidazoline hydrochloride and 42.6g deionized water, stir at room temperature Dissolve uniformly. Put all the primers into a four-necked flask connected with a stirrer, thermometer, condenser and nitrogen tube;

[0059] 3) Polymerization reaction: Fill the flask with primer for 20 minutes with nitrogen to remove oxygen, while stirring, the water bath is heated up, and the temperature in the flask is stabilized at 75 ℃, and then t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com