Optical fiber dividing box

A fiber distribution box and optical fiber technology, which is applied in the direction of fiber mechanical structure, coating, anti-corrosion coating, etc., can solve the problems of easy corrosion and rust, high cost, easy damage of plastic wiring boxes, etc., and achieves low cost and simple structure. , The effect of not easy to rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

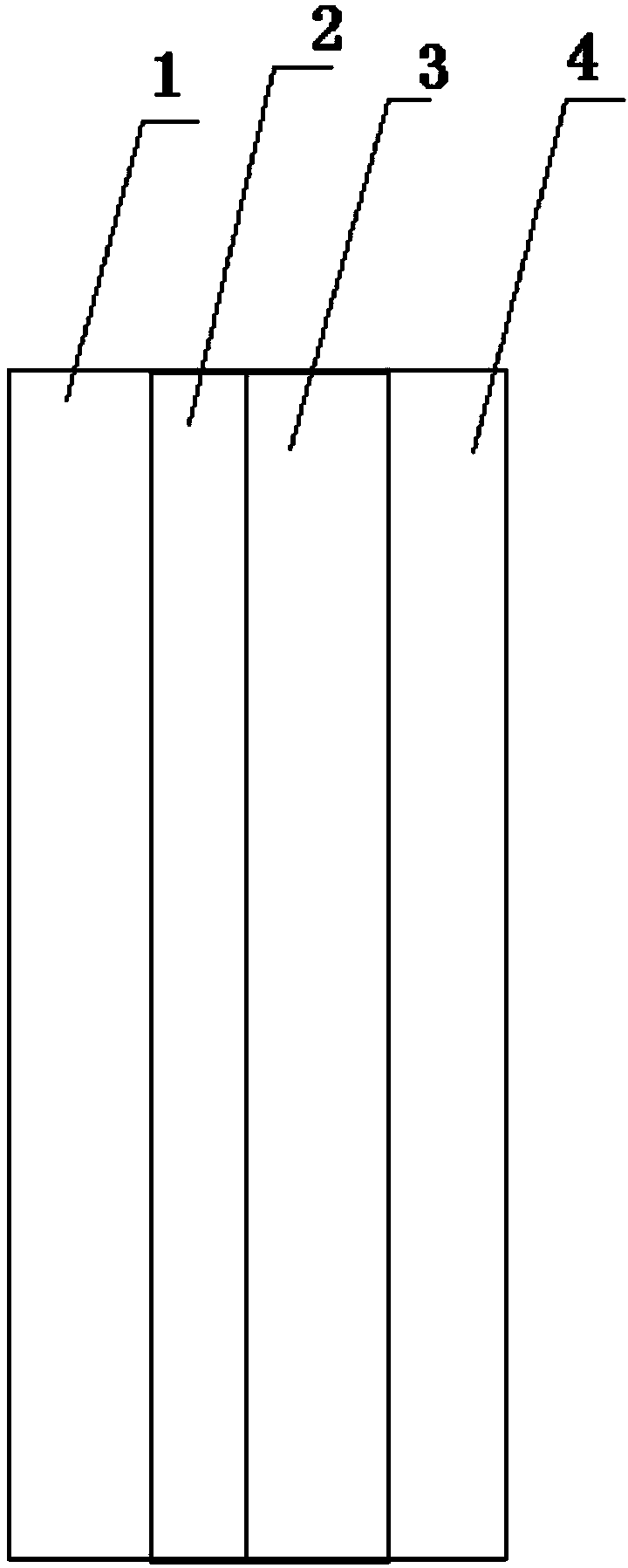

[0013] The optical fiber distribution box includes an aluminum alloy box body 1, an anti-corrosion coating 2, an anti-radiation coating 3 and a paint layer 4 from the inside out.

[0014] The aluminum alloy box 1 is composed of the following mass percentages: 5% magnesium, 2% silicon, 3.2% iron, 2.5% ductile iron, 0.6% titanium, 2% nickel-chromium alloy, and the rest are aluminum.

[0015] The anti-corrosion coating 2 is composed of the following parts by mass: 50 parts of bisphenol A epoxy resin, 6 parts of butyl rubber, 8 parts of flame retardant, 1 part of dimethylethanolamine, 25 parts of selenium acetylacetonate, 5 parts of lime powder, 5-15 parts of bentonite, 5 parts of titanium dioxide, 5 parts of composite iron phosphorus powder, 2 parts of barium sulfate filler, 8 parts of deionized water.

[0016] The anti-radiation coating 3 is composed of the following parts by mass: 60 parts of polyurethane resin, 75 parts of polyurethane adhesive, 3 parts of crosslinking agent,...

Embodiment 2

[0019] The optical fiber distribution box includes an aluminum alloy box body 1, an anti-corrosion coating 2, an anti-radiation coating 3 and a paint layer 4 from the inside out.

[0020] The aluminum alloy box 1 is composed of the following mass percentages: 5% magnesium, 2% silicon, 3.2% iron, 2.5% ductile iron, 0.6% titanium, 8% nickel-chromium alloy, and the rest are aluminum.

[0021] The anti-corrosion coating 2 is composed of the following parts by mass: 50 parts of bisphenol A epoxy resin, 6 parts of butyl rubber, 8 parts of flame retardant, 2 parts of dimethylethanolamine, 15 parts of selenium acetylacetonate, 5 parts of lime powder, 5-15 parts of bentonite, 5 parts of titanium dioxide, 8 parts of composite iron phosphorus powder, 1 part of barium sulfate filler, 12 parts of deionized water.

[0022] The anti-radiation coating 3 is composed of the following parts by mass: 80 parts of polyurethane resin, 75 parts of polyurethane adhesive, 3 parts of crosslinking agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com