Paddy-rice controlled-release fertilizer, and preparation method and application thererof

A technology of controlled-release fertilizer and rice, applied in the field of controlled-release fertilizer, can solve the problems of residual pollution, expensive coating materials, etc., achieve good effect, simple production process, and reduce agricultural non-point source pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

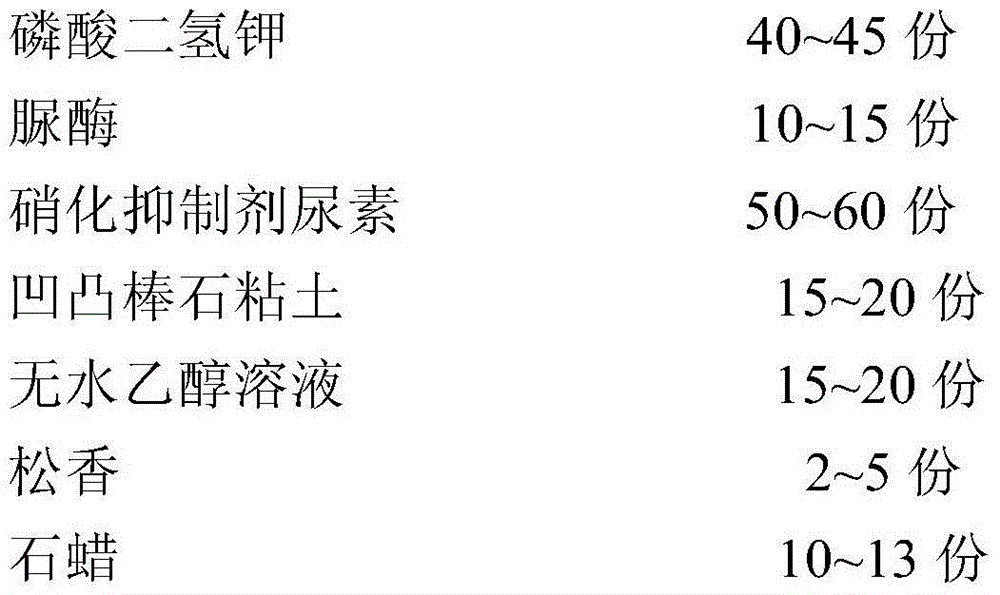

[0034] A controlled-release fertilizer for rice, comprising the following raw materials in parts by weight:

[0035]

[0036]

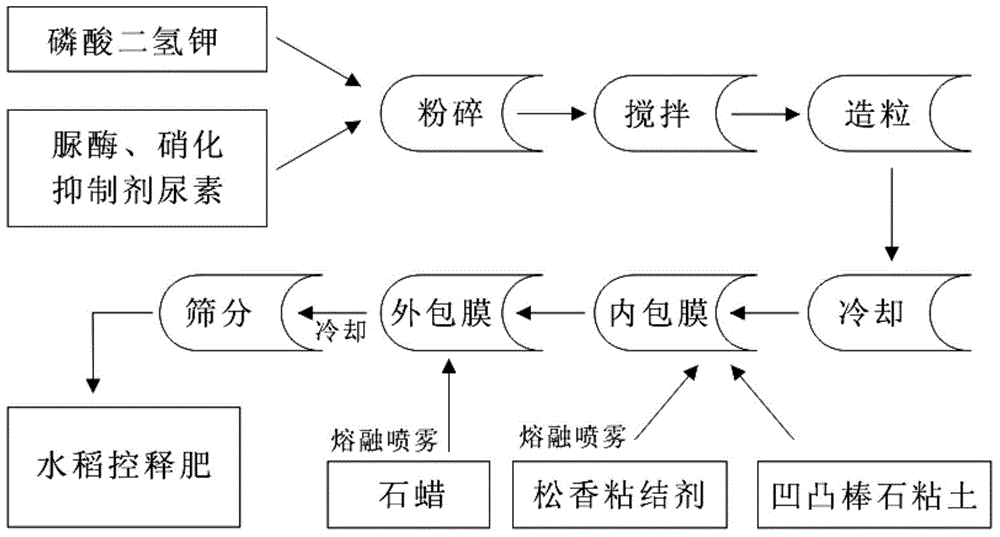

[0037] The above-mentioned controlled-release fertilizer for rice comprises the following preparation steps:

[0038] (1) After potassium dihydrogen phosphate and nitrification inhibitor urea are pulverized, add urease, mix evenly with a mixer, and then send it to a YSL-80 granulator with a particle size of 3.2-4mm, and then cool to room temperature;

[0039] (2) Preheat the granular fertilizer prepared in step (1) in a BY300A type coating machine, dissolve 2 parts of rosin with 15 parts of absolute ethanol, and use a 1000W electronic multipurpose furnace to dissolve the rosin-ethanol mixture, K- Type 3 spray gun is directly sprayed onto the surface of nitrogen, phosphorus and potassium compound fertilizer particles, and 15 parts of attapulgite powder is added, the rotation speed is controlled at 60-70rpm, the inclination angle of the drum is 45...

Embodiment 2

[0047] Embodiment 2: The operation steps and method are the same as above, except that the mass percentage of the inner envelope layer is 12.94%.

Embodiment 3

[0048] Embodiment 3: The operation steps and method are the same as above, except that the mass percentage of the inner envelope layer is 19.07%.

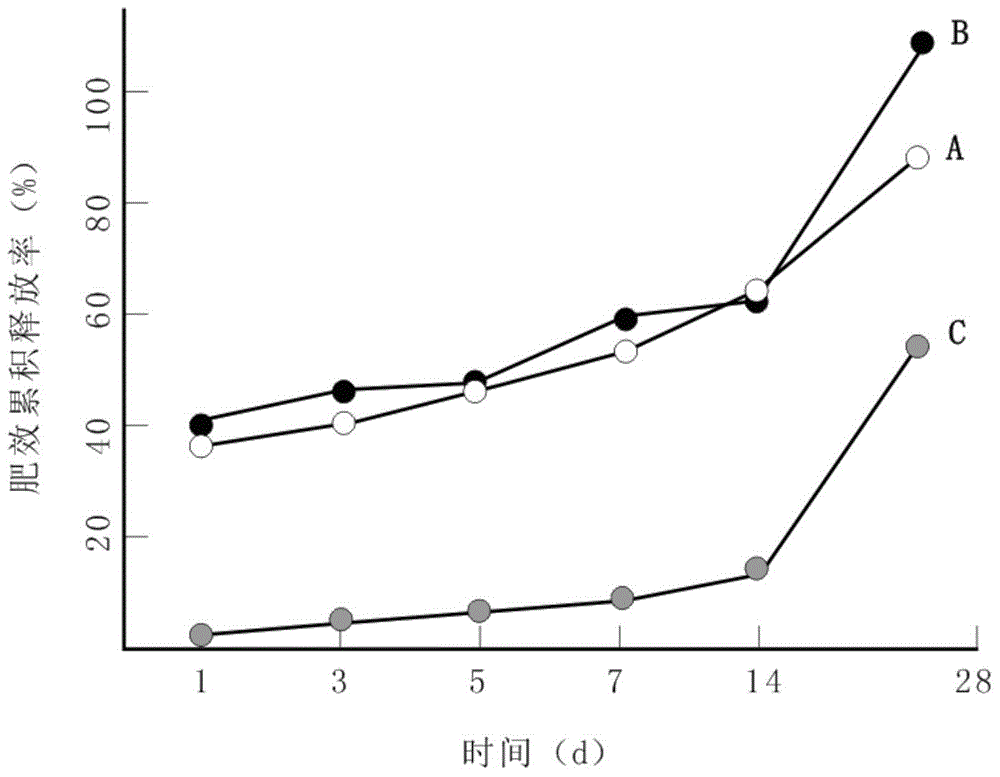

[0049]The rice "Fengyou 301" was selected for the experiment, and the location was Liangjiashan Township, Shulan City, Jilin Province. The first 1-3 days after fertilization of embodiment 1, release amount is 4% of total amount; The 7th-10 day after fertilization, release amount is 11% of total amount; The 15th-20 day after fertilization, release amount It is 32% of the total amount; 24-28 days, the release amount is 55% of the total amount. The first 1-3 days after fertilization of embodiment 2, release amount is 10% of total amount; The 7th-10 day after fertilization, release amount is 20% of total amount; The 15th-20 day after fertilization, release amount 45% of the total amount; 24-28 days, the release amount is 70% of the total amount. The first 1-3 days after fertilization of embodiment 3, release amount is 8% of total amo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com