H acid denitration waste gas resource utilization method

A technology for recycling and denitrification, applied in the field of H acid denitrification waste gas recycling, can solve the problems of high treatment cost, high cost, large consumption of sodium hydroxide, etc., and achieve the effects of stable nitric acid concentration, efficient absorption and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Existing technology that does not adopt reclaiming dilute nitric acid

[0034] Add H acid sulfonated material (the amount of substance is 5kmol, and the total acidity of sulfonated compound is 70.2%) in the nitration kettle, open the cooling water and cool down to 55°C, then add 98% nitric acid 418kg from the nitric acid metering tank (the converted nitric acid amount is 6.5kmol), the nitrification temperature is controlled at 55 ± 2 ℃, and the time of adding nitric acid is 4~5 hours, and after nitrification finishes, it is incubated for 0.5 hour again, sampling analysis, the purity of nitrate (main product) is at 80.3%, yield ( According to nitrous value) at 95.7%.

Embodiment 2

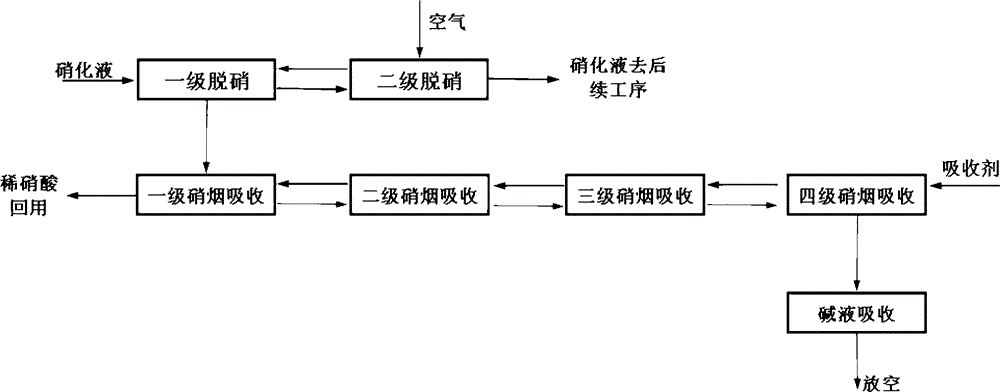

[0035] Example 2: Continuous denitrification recovery dilute nitric acid reuse to denitrification process

[0036]Take H acid nitration liquid (nitration liquid feed rate is 3000L / h) and water according to the volume ratio of 1:0.4 into the first-level denitrification kettle continuously, the overflow of the first-level denitrification kettle enters the second-level denitration kettle, and the denitrification temperature is controlled at 60±5℃, while blowing air from the secondary denitrification kettle, the exhaust gas from the secondary denitrification kettle is blown into the first-stage denitrification kettle, and the exhaust gas from the first-stage denitrification kettle enters the first-stage smoke absorption tower, and the absorption liquid is sprayed in the tower at room temperature Leaking and absorption (the spraying operation of the following towers is the same), the exhaust gas of the first-level gunpowder smoke absorption tower enters the second-level gunpowder sm...

Embodiment 3

[0038] Embodiment 3: Intermittent denitrification reuse

[0039] Add 3000L of nitrates into the denitrification pot, open the intake valve of the nitrogen oxide absorption circulation system, and then add 1200L of water to the denitrification pot from the water metering tank within 1.5 hours, and at the same time, inject compressed air to bubble, and the denitrification waste gas enters the first-level smoke absorption tower , spray absorption with absorption liquid at room temperature in the tower (the spraying operation of the following towers is the same), the exhaust gas of the first-stage gunpowder smoke absorption tower enters the second-stage gunpowder smoke absorption tower, the exhaust gas of the second-stage gunpowder smoke absorption tower enters the third-stage gunpowder smoke absorption tower, and the third-stage gunpowder smoke absorption tower exhaust enters the third-stage gunpowder smoke absorption tower The tail gas of the first-grade gunpowder smoke absorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com