Electricity-conducting and antibacterial polyamide 6/ polypropylene composite material and preparation method thereof

An antibacterial polyamide and composite material technology is applied in the field of plastic modification to achieve the effects of broadening the application range, improving thermal conductivity and electrical conductivity, and simple preparation process and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

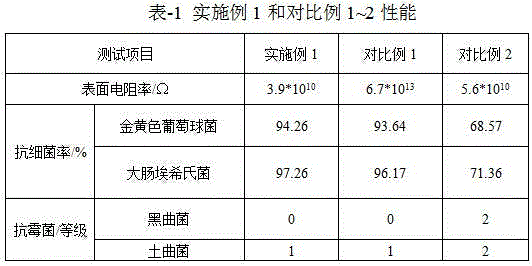

Examples

Embodiment 1

[0063] (1) Preparation of modified graphene powder:

[0064] Place the raw graphene A in an oven at 140°C for 8 hours, and then mix the dried graphene micropowder with the acid solution made by mixing concentrated sulfuric acid and concentrated nitric acid in a volume ratio of 3:5 in a mass ratio of 1:6.5 Mix, then heat and reflux under stirring, the heating temperature is 160°C, and the treatment time is 28 hours. After taking out the treated product, wash it repeatedly with distilled water until it is neutral, and then put it in a 140°C oven to dry for 16 hours.

[0065] The above-mentioned dried graphene and coupling agent-absolute ethanol solution were mixed evenly according to the mass ratio of 1:6, and the obtained slurry was put into a ball mill with a rotation speed of 450 rpm for 3.5 hours, and finally placed in a vacuum of 140 Dry in an oven at ℃ for 16 hours to obtain modified graphene micropowder;

[0066] The coupling agent-absolute ethanol solution is mi...

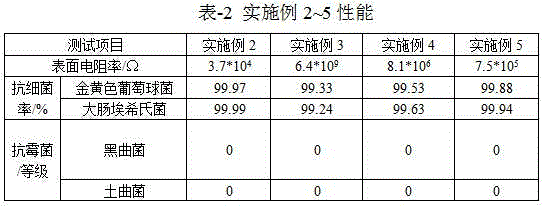

Embodiment 2

[0079] (1) Preparation of modified graphene powder:

[0080] Place the raw graphene B in an oven at 140°C to dry for 8 hours, then mix the dried graphene micropowder with the acid solution made by mixing concentrated sulfuric acid and concentrated nitric acid in a volume ratio of 3:5 in a mass ratio of 1:6.5 Mix, then heat and reflux under stirring, the heating temperature is 160°C, and the treatment time is 28 hours. After taking out the treated product, wash it repeatedly with distilled water until it is neutral, and then put it in a 140°C oven to dry for 16 hours.

[0081] The above-mentioned dried graphene and coupling agent-absolute ethanol solution were mixed evenly according to the mass ratio of 1:6, and the obtained slurry was put into a ball mill with a rotation speed of 450 rpm for 3.5 hours, and finally placed in a vacuum of 140 Dry in an oven at ℃ for 16 hours to obtain modified graphene micropowder;

[0082] The coupling agent-absolute ethanol solution is...

Embodiment 3

[0087] (1) Preparation of modified graphene powder:

[0088] Place the raw graphene B in an oven at 140°C to dry for 8 hours, then mix the dried graphene micropowder with the acid solution made by mixing concentrated sulfuric acid and concentrated nitric acid in a volume ratio of 3:5 in a mass ratio of 1:6.5 Mix, then heat and reflux under stirring, the heating temperature is 160°C, and the treatment time is 28 hours. After taking out the treated product, wash it repeatedly with distilled water until it is neutral, and then put it in a 140°C oven to dry for 16 hours.

[0089] The above-mentioned dried graphene and coupling agent-absolute ethanol solution were mixed evenly according to the mass ratio of 1:6, and the obtained slurry was put into a ball mill with a rotation speed of 450 rpm for 3.5 hours, and finally placed in a vacuum of 140 Dry in an oven at ℃ for 16 hours to obtain modified graphene micropowder;

[0090] The coupling agent-absolute ethanol solution is m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com