Liquid strain of edible mushrooms and method for producing liquid strain of edible mushrooms

A production method and technology of liquid strains, applied in botany equipment and methods, applications, gardening, etc., can solve the problems of unsuitable shiitake mushrooms, difficult pollution, weak growth of strains, etc., to achieve long-term preservation and transportation, reduce Production cost and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of the culture medium used in the embodiment is, the Moringa oleifera sawdust (the part between 20-40 meshes of sawdust particles) and the nutrient solution are mixed and prepared in a weight ratio of 1:1.2, and the formula of the nutrient solution is prepared with 10% The obtained bran water was incubated at 80-93° C. for 1 hour and then filtered with 4 layers of gauze. Add 2 grams of sucrose, 0.2 grams of potassium dihydrogen phosphate, and 0.1 grams of magnesium sulfate to each 100 ml of filtrate to adjust the pH to 6.0. Then the medium was sterilized at 121°C for 30 minutes, and then cooled to 30°C under sterile conditions for use.

[0052] The detection of the content of solid strains in liquid strains is carried out in accordance with the method specified in NY / T1742-2009, General Technical Requirements for Edible Fungi Strains.

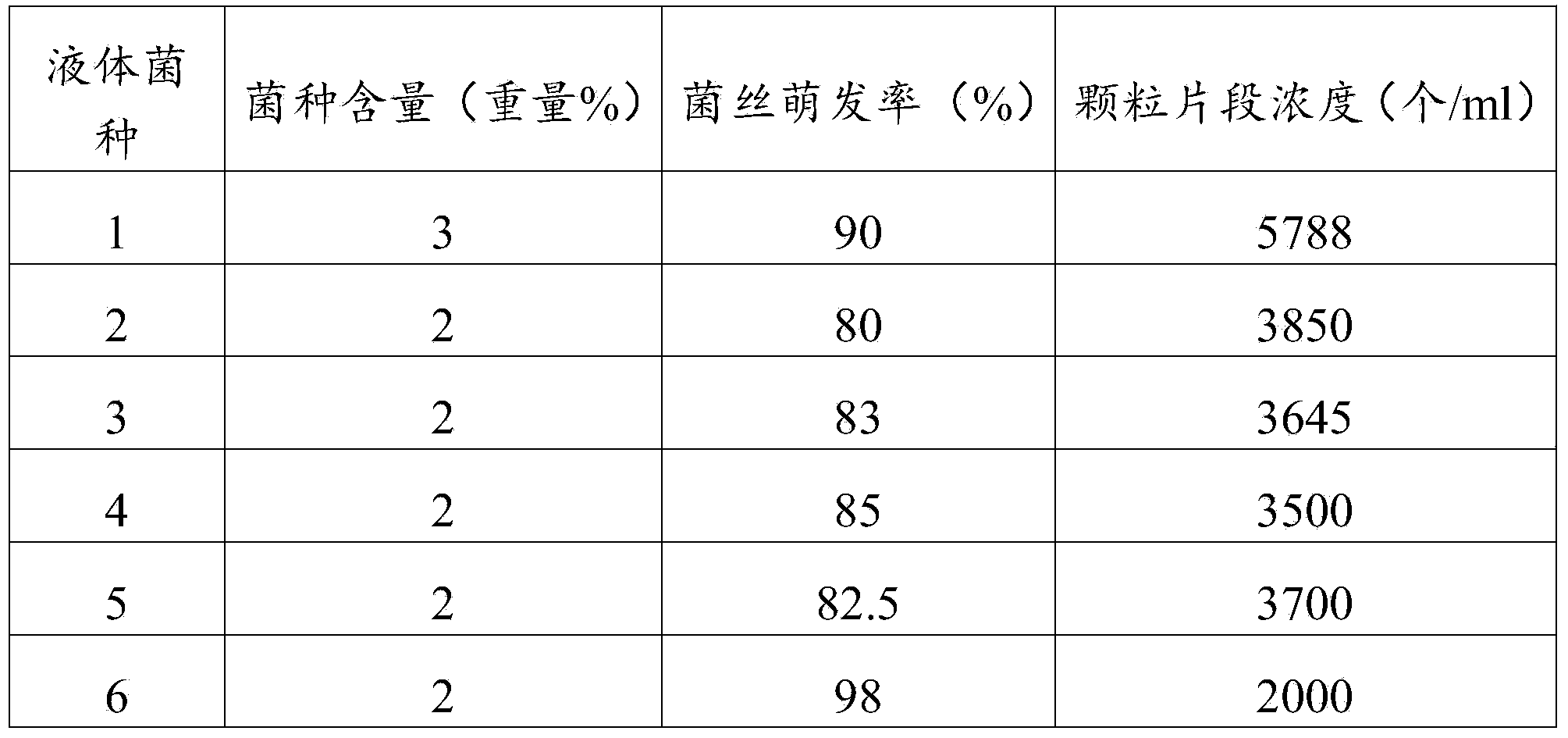

[0053] The detection method of mycelial germination rate is as follows: the liquid strain of edible fungus is co...

Embodiment 1

[0056] This embodiment is used to illustrate the method for producing edible fungus liquid strains provided by the present invention.

[0057] Inoculate the mushroom strain (Qingke 20) into PDA medium for activation and culture to obtain mycelium; then transfer the mycelium to solid wood chip medium at a ratio of 4%, and place it at 25°C for fermentation and culture for 30 1 day, obtain 100g mycelium block culture; Under sterile conditions, the block culture is smashed into the powdery granule culture of particle size not more than 0.5cm fritter, the powdery granule culture is with 3 The thickness of -4cm is tiled in the culture tray, sealed, protected from light, and cultured at a constant temperature of 25°C for 3 days; Add 250ml of sterile water at 5000rpm / min and beat for 30s at a rotating speed of 5000rpm / min to prepare a mother liquor, and then mix 4750ml of agar solution with a concentration of 0.2% with the prepared mother liquor to obtain 5000ml of shiitake mushroom l...

Embodiment 2

[0059] This embodiment is used to illustrate the method for producing edible fungus liquid strains provided by the present invention.

[0060] The same method as in Example 1 was used to prepare the liquid spawn of mushrooms, except that the amount of 0.2% agar solution added was 4500 ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com