Acid rain-resistant acrylate exterior wall paint

A technology of acrylic ester and exterior wall paint, which is applied in the direction of anti-corrosion coatings and coatings, which can solve the problems of accelerated corrosion and aging of buildings, discoloration of paint coatings, and easy corrosion by acid rain, so as to enhance crack resistance and paint The effect of film compactness, waterproof and anti-corrosion performance enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

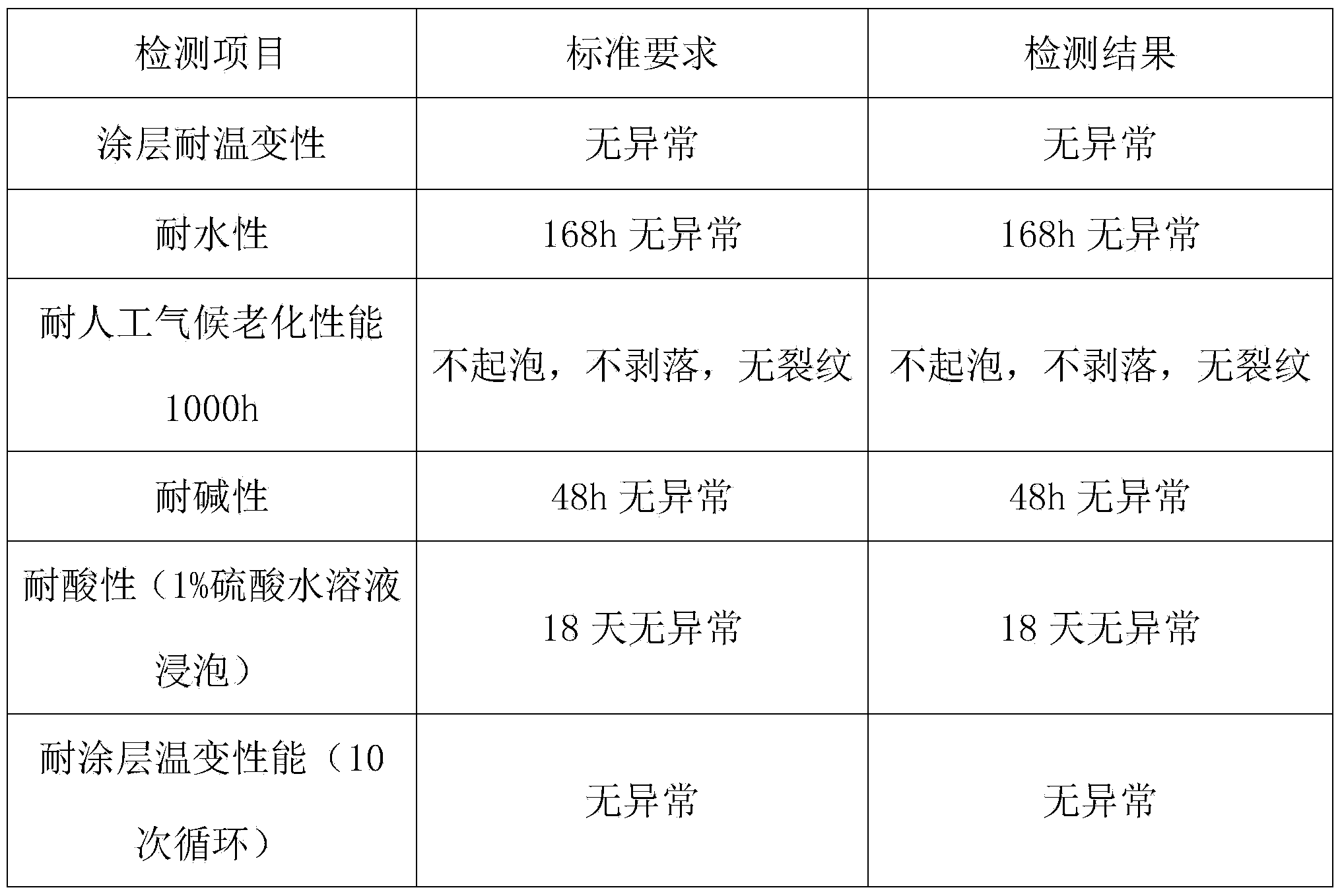

Examples

Embodiment 1

[0015] A kind of acid rain resistant acrylic ester exterior wall paint that the present invention proposes, its raw material comprises by weight: 40 parts of base materials, 6 parts of F-974 film-forming aids and 40 parts of auxiliary materials;

[0016] The raw materials of the base material include by weight: 60 parts of CB-700 acrylic emulsion, 30 parts of silica sol, 6 parts of coupling agent, and 1 part of emulsifier, wherein the silane coupling agent is silane KH550; the following process is used to prepare : Put CB-700 acrylic emulsion and silica sol in a reactor, stir evenly at a temperature of 70°C and a rotating speed of 1000r / min, then add a coupling agent and an emulsifier and stir evenly to obtain a base material;

[0017] The auxiliary materials include by weight: 15 parts of white cement, 20 parts of titanium dioxide, 15 parts of wollastonite powder, 5 parts of talc powder, 0.8 parts of wetting and dispersing agent, 1 part of defoamer, 1 part of hydroxyethyl cell...

Embodiment 2

[0020] A kind of acid rain resistant acrylate exterior wall paint that the present invention proposes, its raw material comprises by weight: 47 parts of base materials, 3 parts of F-974 film-forming aids and 44 parts of auxiliary materials;

[0021] The raw materials of the base material include by weight: 42 parts of CB-700 acrylic emulsion, 38 parts of silica sol, 5 parts of coupling agent, and 2 parts of emulsifier, wherein the emulsifier is composed of 80% dodecyl Sodium sulfate and 20% sodium methacrylate hydroxypropyl sulfonate, the silane coupling agent is composed of silane KH550 and silane KH551; the following process is used to prepare: CB-700 acrylic acid emulsion and silica sol are placed in the reactor, Stir evenly at a temperature of 68°C and a rotational speed of 1240r / min, then add a coupling agent and an emulsifier and stir evenly to obtain a base material;

[0022] The auxiliary materials include by weight: 10 parts of white cement, 22 parts of titanium dioxi...

Embodiment 3

[0025] A kind of acid rain resistant acrylate exterior wall paint that the present invention proposes, its raw material comprises by weight: 50 parts of base material, 2 parts of F-974 film-forming auxiliary agent and 50 parts of auxiliary materials;

[0026] The raw materials of the base material include by weight: 50 parts of CB-700 acrylic emulsion, 40 parts of silica sol, 2 parts of coupling agent, and 4 parts of emulsifier, wherein the emulsifier is composed of 60% dodecyl Sodium sulfate and 40% sodium methacrylate hydroxypropyl sulfonate, the silane coupling agent is silane KH551; the following process is used to prepare: CB-700 acrylic acid emulsion and silica sol are placed in a reactor, and the temperature is 65 °C, stirring evenly at a rotating speed of 1300r / min, then adding a coupling agent and an emulsifier and stirring evenly to obtain a base material;

[0027] The auxiliary materials include by weight: 5 parts of white cement, 25 parts of titanium dioxide, 5 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com