Enzyme preparation method of sea collagen peptide capable of promoting wound healing

A technology of marine collagen and collagen peptides, which is applied to the preparation methods of peptides, chemical instruments and methods, animal/human proteins, etc., can solve the problems of lack, unreasonable use of ingredients, waste of processing by-products, etc., to achieve Improve the competitiveness of enterprises, promote healthy and sustainable development, and increase the effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

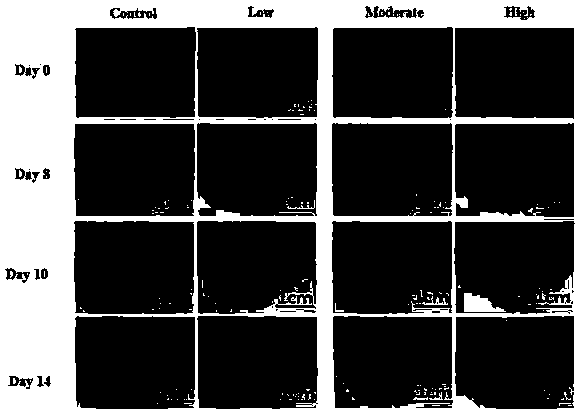

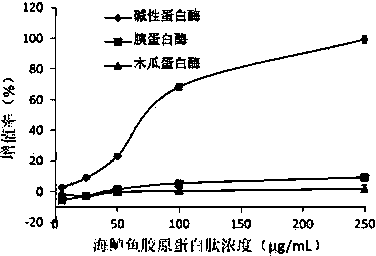

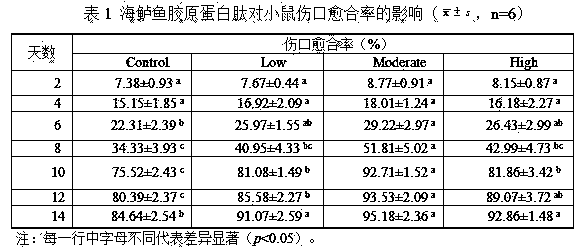

Image

Examples

Embodiment 1

[0056] (1) Wash and mince the skin and bones of 1kg sea bass, soak in 15L of 0.1mol / L sodium hydroxide solution for 15h to remove impurities; wash with distilled water until neutral, then use 15L of 0.6 Soak in mol / L hydrochloric acid for 15 hours to decalcify; wash with distilled water until neutral, and finally soak in 2L of 10% ether for 24 hours, repeat twice, and degrease for a total of 48 hours;

[0057] (2) After the degreasing is completed, wash repeatedly with distilled water, drain, soak in 1L of 0.5mol / L acetic acid solution for 3 days, centrifuge at 4000r / min for 20min, take the supernatant, and freeze-dry to obtain 200g of collagen;

[0058] (3) Add 2L of distilled water and 4.6g of alkaline protease to 200g of collagen, and enzymolyze it for 3.0h at a temperature of 45°C and a pH value of 9.0, and the extraction rate of collagen peptides is 48%;

[0059] (4) Heat in a water bath at 90°C for 10 minutes to inactivate the enzyme;

[0060] (5) Add 10g of activated c...

Embodiment 2

[0067] (1) Wash and mince the fish head and fish bones of 300g sea bass, soak them in 6L of 0.1mol / L sodium hydroxide solution for 30h to remove impurities; Soak in mol / L hydrochloric acid for 30 hours to decalcify; wash with distilled water until neutral, and finally soak in 0.9L of 10% ether for 24 hours, repeat twice, and degrease for a total of 48 hours;

[0068] (2) After the degreasing is completed, wash with distilled water, drain, soak in 0.3L of 0.5mol / L acetic acid solution for 3 days, centrifuge at 4500r / min for 15min, take the supernatant, and freeze-dry to obtain 30g of collagen;

[0069] (3) Add 0.3L of distilled water and 0.9g of alkaline protease to 30g of collagen, and enzymolyze it for 4.0h at a temperature of 50°C and a pH value of 9.5, and the extraction rate of collagen peptides is 42%;

[0070] (4) Heat in a water bath at 95°C for 15 minutes to inactivate the enzyme;

[0071] (5) Add 1.8g of activated carbon and heat in a water bath at 45°C for 50 minute...

experiment example 3

[0079] (1) Wash and mince the skin and bones of 1kg sea bass, soak in 20L of 0.1mol / L sodium hydroxide solution for 24 hours to remove impurities; wash with distilled water until neutral, then use 20L of 0.6 Soak in mol / L hydrochloric acid for 24 hours to decalcify; wash with distilled water until neutral, and finally soak in 20L of 10% ether for 24 hours, repeat twice, and degrease for a total of 48 hours;

[0080] (2) After the degreasing is completed, wash repeatedly with distilled water, drain, soak in 1L of 0.5mol / L acetic acid solution for 2 days, centrifuge at 4400r / min for 15min, take the supernatant, and freeze-dry to obtain 200g of collagen;

[0081] (3) Add 2L of distilled water and 4.6g of alkaline protease to 200g of collagen, and enzymolyze it for 2.0h at a temperature of 45°C and a pH value of 9.0, and the extraction rate of collagen peptides is 45%;

[0082] (4) Heat in a water bath at 95°C for 10 minutes to inactivate the enzyme;

[0083] (5) Add 12g of activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com