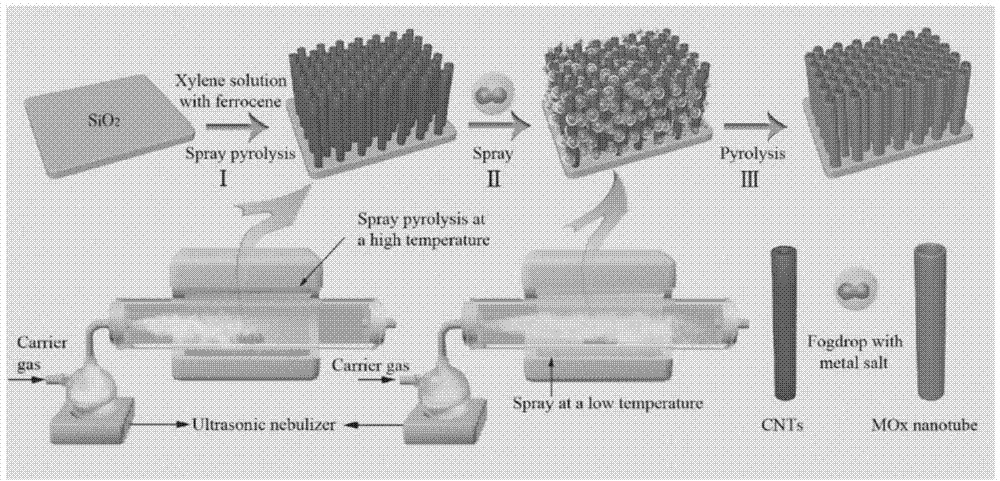

Method utilizing atomized ethanol assisted penetration high-temperature pyrolysis to prepare carbon nanotube array/transition metal oxide coaxial structural material

A technology of carbon nanotube arrays and transition metals, applied in the field of nanomaterials, can solve problems such as limited space between tubes, high density of carbon nanotubes, and unintended performance of three-dimensional composite materials, achieving stable composite structure and adjustable coating thickness tune effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Preparation of the growth substrate of the quartz wafer

[0029] Take a rectangular quartz plate with a size of 1 cm×2 cm and put it into H 2 SO 4 : H 2 o 2 Sonicate in the mixed solution (volume ratio is selected according to needs) for a certain period of time, then wash with ethanol, sonicate for a few minutes, and finally soak in high-purity water for use. Dry the cleaned quartz slices with high-purity nitrogen gas for later use.

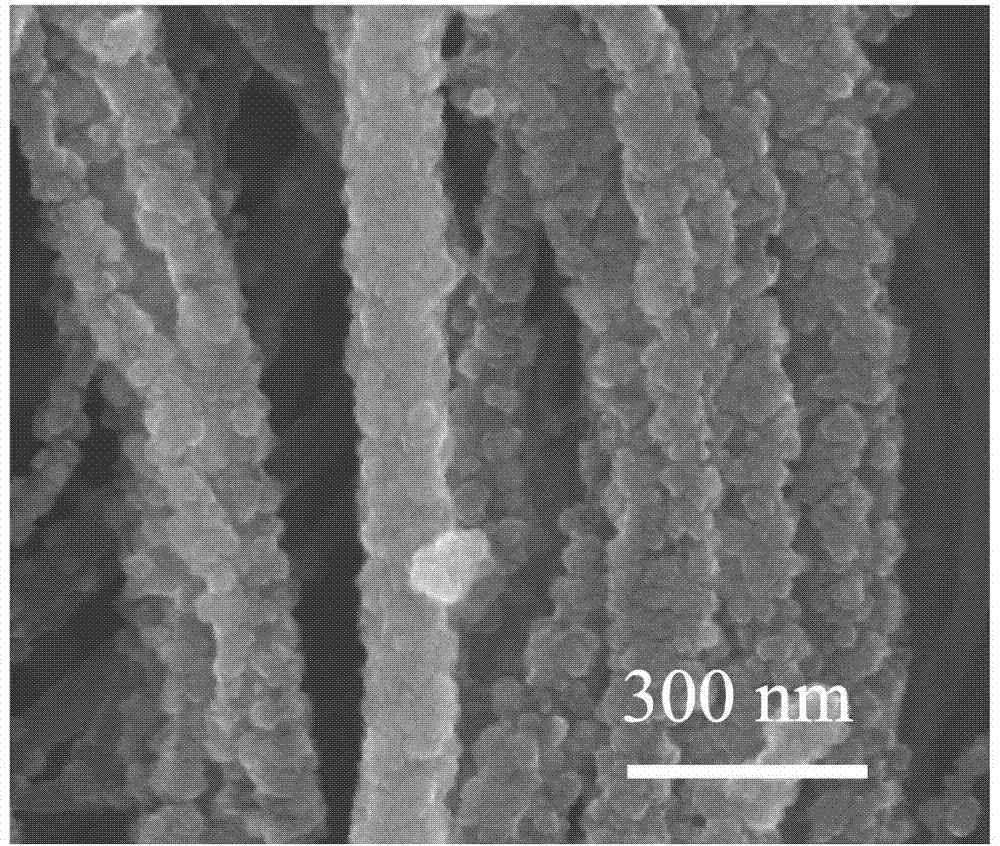

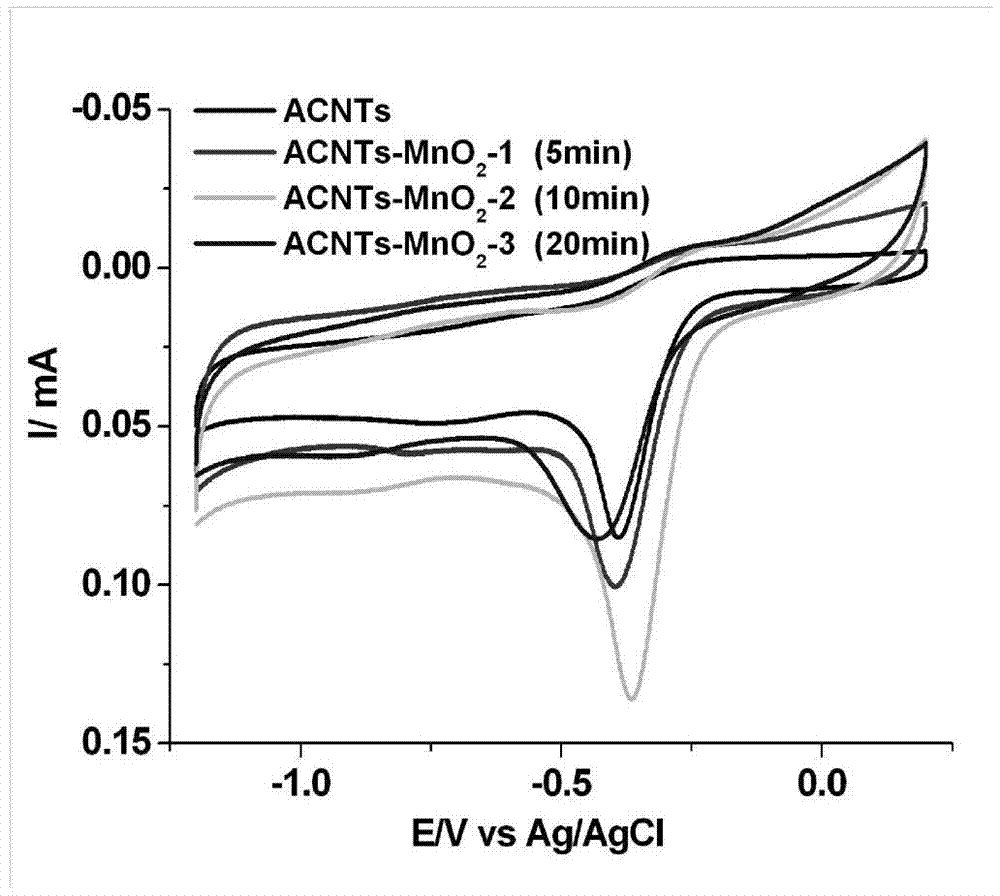

[0030] 2) Carbon nanotube / manganese oxide (MnO 2 -CNTs) composites

[0031] a. Prepare a certain concentration of ferrocene and xylene solution, pour it into an atomizing bottle, and place it in the atomizer.

[0032] b. Put the quartz piece in the quartz tube, let it be in the furnace temperature zone of the tube furnace, connect the experimental device, open the nitrogen bottle, and after confirming that the gas circuit is well sealed and the atomization of the atomizer is normal, put the The tube furnace is heated up to the ...

Embodiment 2

[0044] According to the process of Example 1, a certain amount of ethanol solution of n-butyl titanate (or other titanium compounds) is used as the precursor solution. Under the condition of min, the carbon nanotube array / titanium oxide coaxial composite material was prepared by reacting for a certain period of time, and a series of morphological and structural characterizations were performed on the prepared composite material.

Embodiment 3

[0046] According to the process of Example 1, a certain amount of ethanol solution of cobalt linoleate soap (or other cobalt compounds) is used as the precursor solution, the pyrolysis reaction temperature is 400-550 °C, and the flow rate of nitrogen gas is 400-600 mL / Under the condition of min, the coaxial composite material of carbon nanotube array / cobalt oxide was prepared by reacting for a certain period of time, and a series of morphological and structural characterizations were performed on the prepared composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com