Preparation method of denitrification ceramic catalyst carrier

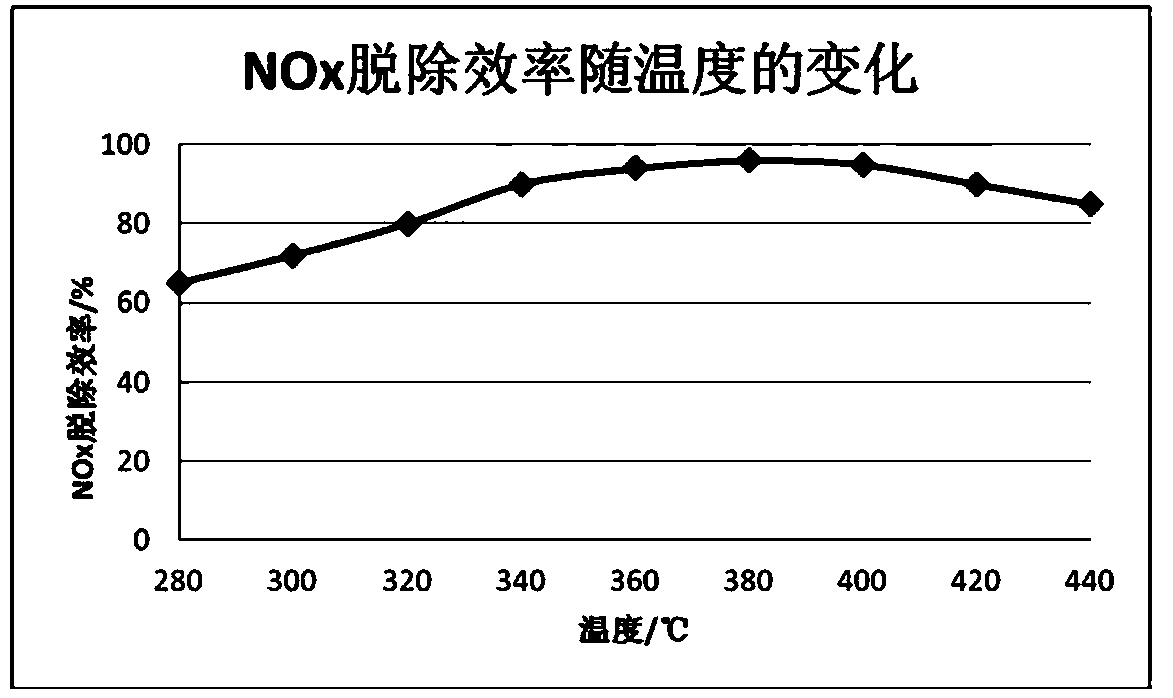

A ceramic catalyst and carrier technology, applied in the field of preparation of denitrification ceramic catalyst carrier, can solve the problems of reducing one drying process, low NOx removal rate, uneven loading, etc., achieve good economic and environmental benefits, and ensure activity uniformity , the effect of increasing the scale of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

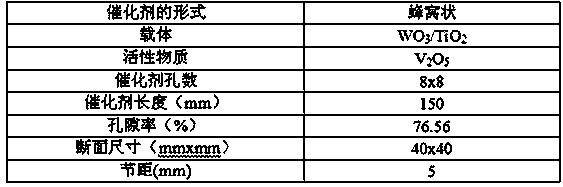

[0023] 100 kg of anatase TiO 2 1. Add 200 kg of clay to the beater for dry mixing, and then add 75 kg of deionized water to beat at a speed of 320 r / min after mixing evenly; add 6 kg of tungsten trioxide after 0.5 hours, and continue to beat at a speed of 320 r / min 0.5 hours; then use a plate and frame filter press to dehydrate the obtained slurry for 1 hour at a pressure of 0.48MPa and a temperature of 40°C; and finally vacuum dry the obtained material after dehydration in an environment with a relative humidity of 5%. After 2 hours, the drying temperature is 70° C. to obtain the denitration ceramic catalyst carrier.

Embodiment 2

[0025] 100 kg of anatase TiO 2 1. Add 200 kg of clay to the beater for dry mixing, and then add 90 kg of deionized water to beat at a speed of 330 r / min after mixing evenly; add 7 kg of tungsten trioxide after 1 hour, and continue to beat at a speed of 330 r / min 1 hour; then the obtained slurry was dehydrated with a plate and frame filter press at a pressure of 0.44MPa and a temperature of 45°C for 1 hour; finally, the dehydrated material was vacuum-dried in an environment with a relative humidity of 6%. After 2.5 hours, the drying temperature is 70° C. to obtain the denitration ceramic catalyst carrier.

Embodiment 3

[0027] 100 kg of anatase TiO 2 1. Add 150 kg of clay to the beater for dry mixing. After mixing evenly, add 87.5 kg of deionized water to beat at a speed of 340 r / min; add 8 kg of tungsten trioxide after 0.5 hours, and continue to beat at a speed of 340 r / min 1 hour; then the obtained slurry was dehydrated with a plate and frame filter press at a pressure of 0.36MPa and 50°C for 1.5 hours; finally, the dehydrated material was vacuum-dried for 3 hours in an environment with a relative humidity of 7% , and the drying temperature is 65° C. to obtain the denitration ceramic catalyst carrier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com