A kind of modified im-5 molecular sieve and catalyst and application

A molecular sieve, IM-5 technology, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of poor activity stability, decreased toluene conversion, and decreased strong acid centers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

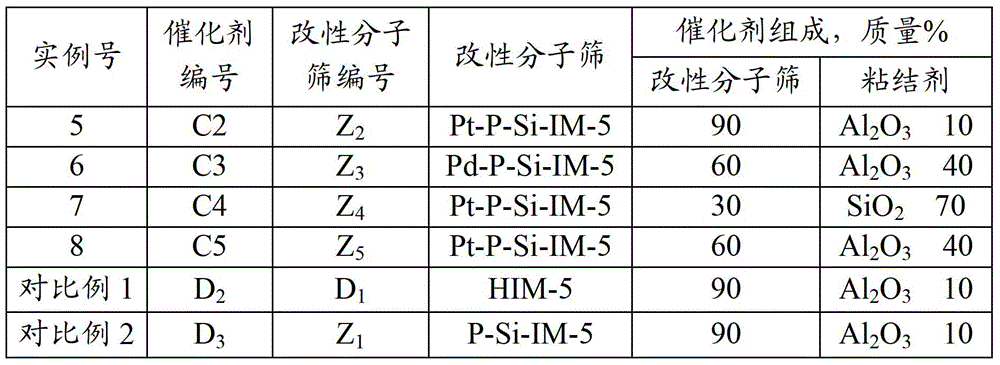

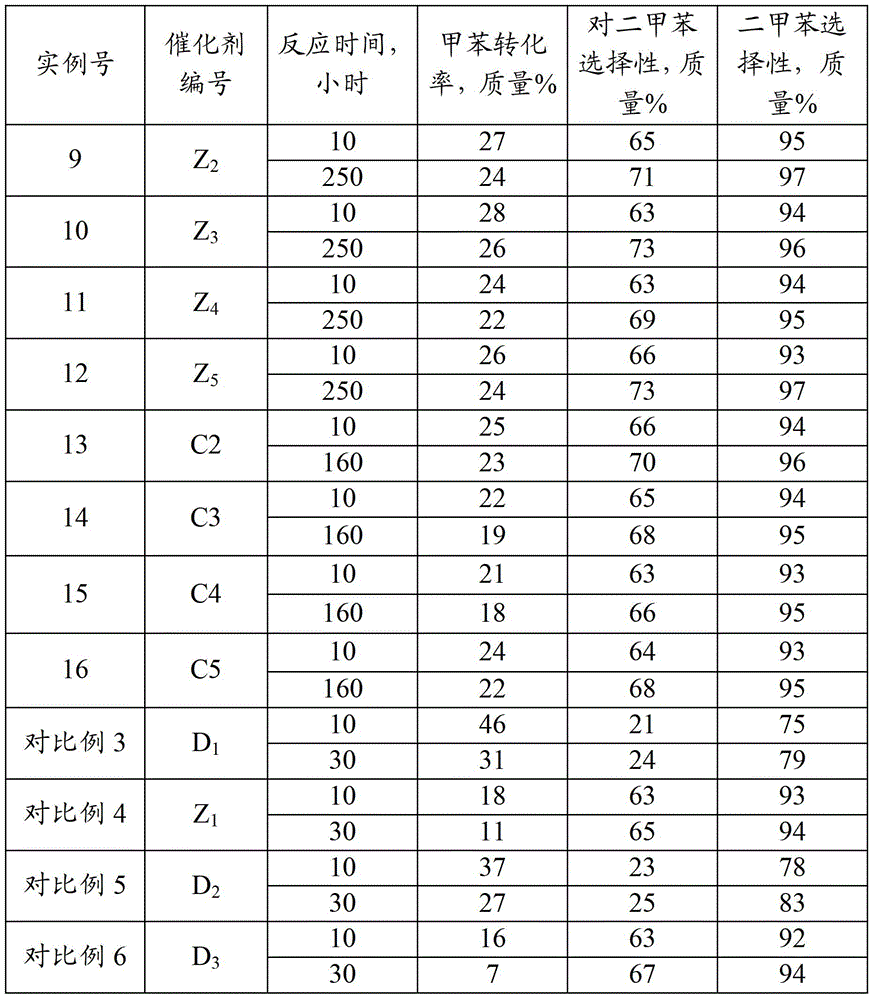

Examples

preparation example Construction

[0016] The preparation method of the molecular sieve provided by the present invention includes impregnating the hydrogen-type IM-5 molecular sieve with a solution of a phosphorus-containing compound, drying and roasting, and then introducing silicon through a method of silicon deposition, and then introducing a noble metal with a compound containing a noble metal after drying and roasting, Dry and roast.

[0017] The modified element of the modified molecular sieve of the present invention is introduced into the molecular sieve in three steps, the first step is to introduce phosphorus by impregnation, and the phosphorus-containing compound used to prepare the impregnation solution is selected from phosphoric acid, ammonium phosphate, ammonium hydrogen phosphate, ammonium dihydrogen phosphate , one or more of triphenylphosphine and trimethyl phosphate. The immersion temperature is 60-85°C, and the time is preferably 1-4 hours.

[0018] In the second step, silicon is introduce...

example 1

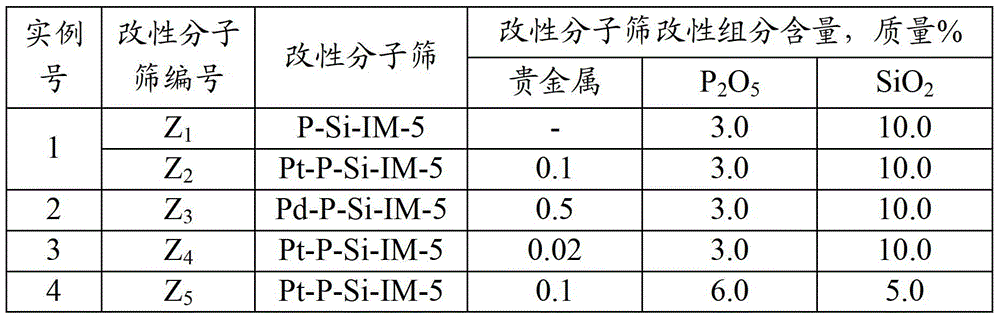

[0037] Prepare the modified IM-5 molecular sieve of the present invention.

[0038] (1) Prepare H-IM-5 molecular sieve.

[0039] SiO 2 / Al 2 o 3The NaIM-5 molecular sieve with a molar ratio of 46.6 was ion-exchanged with ammonium nitrate solution with a concentration of 0.5 mol / L at 80° C. for 3 times, each time for 2 hours. The ion-exchanged molecular sieve was washed with deionized water, dried at 90°C for 2 hours, and calcined at 550°C for 5 hours to obtain HIM-5 molecular sieve D 1 .

[0040] (2) Preparation of modified IM-5 molecular sieve.

[0041] Take 10g molecular sieve D 1 , with 21.0mL ammonium dihydrogen phosphate aqueous solution with a concentration of 0.2mol / L, stirred and impregnated at 60°C for 1 hour, dried at 90°C for 2 hours, and calcined at 550°C for 4 hours to obtain P-IM-5 molecular sieve.

[0042] Take 10g of P-IM-5 molecular sieve and mix it with 18.7mL cyclohexane solution of tetraethyl orthosilicate with a concentration of 2mol / L, put it into ...

example 2

[0045] Get 10g by the P-Si-IM-5 molecular sieve Z prepared by example 1 method 1 , with 23.5 mL of Pd (NO 3 ) 2 The solution was stirred and impregnated at 25°C for 2 hours at a liquid / solid ratio of 3mL / g, dried at 90°C for 2 hours, and calcined at 500°C for 3 hours to obtain Pd-P-Si-IM-5 molecular sieve Z 3 , and the contents of modifying elements are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com