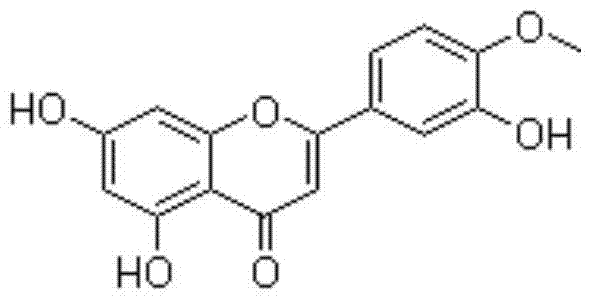

Semi-synthetic method for diosmetin

A diosmin and semi-synthetic technology, applied in chemical instruments and methods, preparation of sugar derivatives, disaccharides, etc., can solve the problems of reduced efficiency and increased production cost, and achieve low production cost, easy operation, and simple synthesis process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

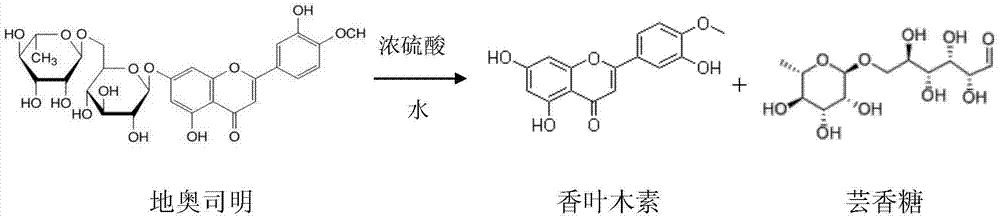

Method used

Image

Examples

Embodiment 1

[0025] (1) Synthesis: Add 1200L of water to the reactor, start stirring, drop in 120kg of diosmin, close the manhole of the reactor, vacuum inhale 240kg of concentrated sulfuric acid, open the vent valve of the reactor, turn on the jacket steam heating, wait When the temperature in the kettle rises to 90°C, close the vent valve and continue heating until the internal pressure of the reactor is 0.08MPa. At this time, the temperature in the kettle is 110°C. Turn down the steam pressure of the jacket to keep the temperature in the reactor at 110-115 ℃, hydrolyze for 10 hours; after the reaction, slowly remove the pressure in the kettle, lower to room temperature, vacuum filter the reaction mixture with a PTFE suction filter, after the suction filtration is completed, wash the filter cake with water until the pH value of the effluent 6-7 to obtain crude geranolin; at the same time, add sodium hydroxide to the filtrate to neutralize to a pH value of 6-7, then add 3.6kg of medicinal ...

Embodiment 2

[0029] (1) Synthesis: add 1200L of water to the reactor, start stirring, drop in 80kg of diosmin, close the manhole of the reactor, vacuum inhale 80kg of concentrated sulfuric acid, open the vent valve of the reactor, turn on the jacket steam heating, wait When the temperature in the kettle rises to 90°C, close the vent valve and continue heating until the internal pressure of the reactor is 0.08MPa. At this time, the temperature in the kettle is 118°C. Turn down the steam pressure of the jacket to keep the temperature in the reactor at 118-120°C. ℃, hydrolysis for 12 hours; after the reaction, slowly remove the pressure in the kettle, lower to room temperature, vacuum filter the reaction mixture with a PTFE suction filter, after the suction filtration is completed, wash the filter cake with water until the pH value of the effluent 6-7 to obtain crude geranolin; at the same time, add sodium hydroxide to the filtrate to neutralize to a pH value of 6-7, then add 2.4kg of medicina...

Embodiment 3

[0033] (1) Synthesis: Add 1500L of water to the reactor, start stirring, drop in 115kg of diosmin, close the manhole of the reactor, vacuum inhale 230kg of concentrated sulfuric acid, open the vent valve of the reactor, turn on the jacket steam heating, wait When the temperature in the kettle rises to 90°C, close the venting valve, continue heating until the internal pressure of the reactor is 0.08MPa, at this time, the temperature in the kettle is 100°C, and turn down the steam pressure of the jacket to keep the temperature in the reactor at 100-110°C. ℃, hydrolyze for 10 hours; after the reaction, slowly remove the pressure in the kettle, lower to room temperature, vacuum filter the reaction mixture with a PTFE suction filter, after the suction filtration is completed, wash the filter cake with water until the pH value of the effluent 6-7 to obtain crude geranolin; at the same time, add sodium hydroxide to the filtrate to neutralize to a pH value of 6-7, then add 3.45kg of me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com