Carbon nanotube-CdTe/CdS nanocomposite and preparation method thereof

A technology of nanocomposite materials and carbon nanotubes, which is applied in the field of nanocomposite materials and its preparation, can solve the problems of carbon nanotubes that cannot find the terminal coil structure and limit research, and achieve high fluorescence intensity and fluorescence stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of NaHTe solution: 0.75mmol NaBH 4 Add 0.375mmol Te powder to 12ml double-distilled water, react in an oil bath at 60°C for 30-60min, and pass the reaction solution through a 0.22μm filter to filter out the precipitate generated by the reaction to obtain a relatively pure NaHTe solution.

[0028] (2) MPA modified Cd 2+ Preparation of precursor solution: 0.25mmol CdCl 2 2.5H 2 O, 52μL (0.6mmol) MPA was dissolved in 200mL double-distilled water, and the pH was adjusted to 8.5 with 1M NaOH, and nitrogen gas was passed for 30min under stirring to obtain Cd modified by MPA stabilizer. 2+ Precursor.

[0029] (3) Preparation of CdTe quantum dots: get 4ml of newly prepared NaHTe and add it to the Cd obtained in step (2) 2+ In the precursor solution, nitrogen gas was refluxed at 100°C for 60 minutes to obtain a CdTe quantum dot solution, which was concentrated to 1 / 4 of the original volume, isopropanol was added dropwise and centrifuged to obtain a precipitat...

Embodiment 2

[0032] (1) Preparation of CdS coating solution: 0.25mmol CdCl 2 2.5H 2 O, 0.25mmol TAA and 1.2mmol MPA were dissolved in 200mL double-distilled water, the pH was adjusted to 8.5 with 1M NaOH, and the CdS coating solution was obtained by blowing nitrogen gas for 30min while stirring. where Cd in the CdS coating solution 2+ : Stabilizer: S 2- The molar concentration ratio is 1:4.8:1.

[0033] (2) Preparation of CdTe / CdS core-shell quantum dots: Add the CdTe obtained in Example 1 to the CdS cladding solution, and reflux nitrogen gas at 100°C for 120 minutes to obtain a CdTe / CdS core-shell quantum dot solution, which is then concentrated To 1 / 4 of the original volume, isopropanol was added dropwise and centrifuged to obtain a precipitate, which was redissolved in a certain volume of double-distilled water for later use.

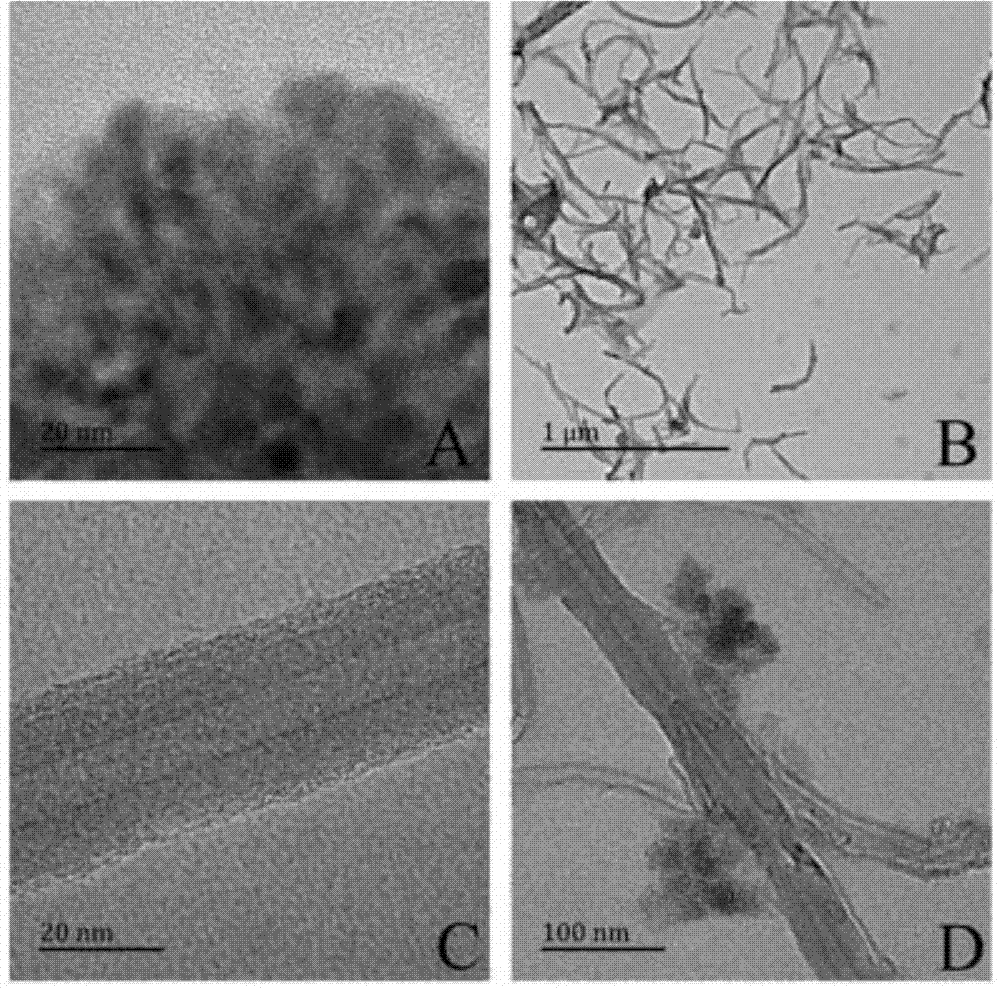

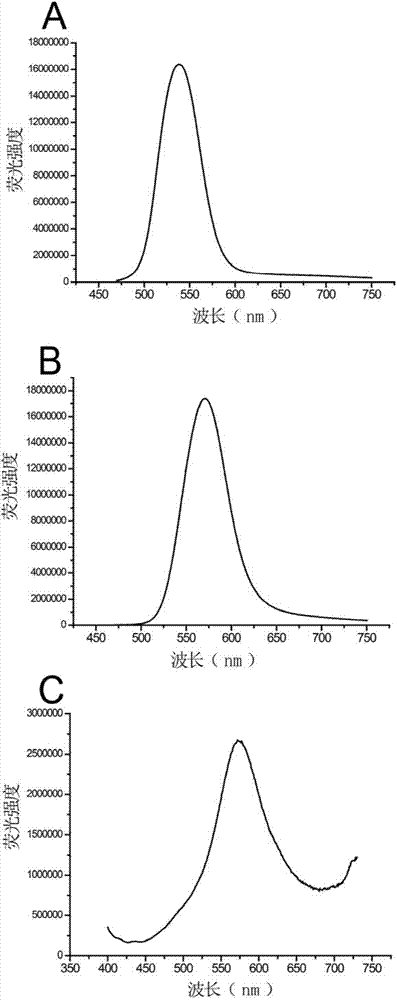

[0034] (3) figure 1 A shows the transmission electron microscope picture of the obtained water-soluble CdTe / CdS core-shell quantum dots. It can be seen from ...

Embodiment 3

[0037] (1) Add 0.2 g of MWCNTs-COOH and 0.2 g of EDC·HCl into 20 mL of DMSO for 3 h of ultrasonic reaction to activate the carboxyl groups on the carbon nanotubes.

[0038] (2) Add 0.3 g of PEI to the above system, and ultrasonically react for 24 hours.

[0039] (3) PEI-MWCNTs can be obtained by removing unreacted impurities in the system by dialysis.

[0040] (4) figure 1 B and C are transmission electron microscope images of PEI-MWCNTs. From Figure B, it can be seen that the dispersion of carbon nanotubes in water can be improved after PEI is used to modify carbon nanotubes. It can be seen from Figure C that the surface of MWCNTs is evenly coated with a layer of PEI, indicating that PEI can be well connected to the surface of carbon nanotubes through covalent bonds.

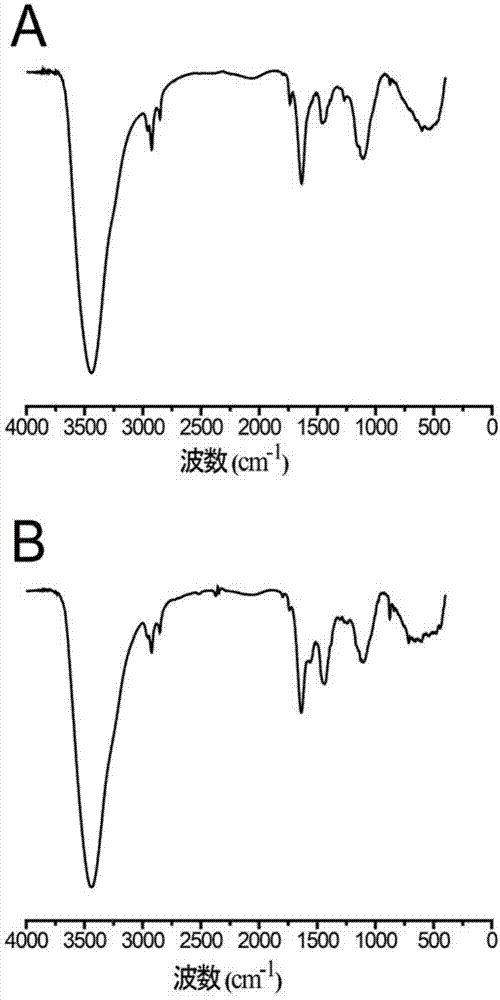

[0041] (5) image 3 A is the infrared spectrum of PEI-MWCNTs. It can be seen from the figure that 2854 and 2917 are the characteristic absorption peaks of PEI -CH2-, and 1448 is the characteristic absorptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com