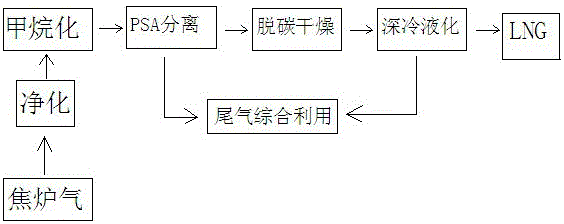

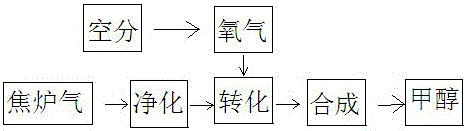

Coking plant co-production method of methanol and liquefied natural gas

A technology for liquefied natural gas and methanol, applied in chemical instruments and methods, preparation of organic compounds, gas fuel, etc., can solve problems such as high requirements for safe operation, lack of molecular economy, high energy consumption in the conversion process, and achieve economic benefits High, eliminate strong exothermic reaction steps, adjust the effect of product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] Coke oven gas 55000Nm from coking system gas holder 3 / h, temperature 40°C, pressure 0~10kPa, component (v%): H 2 61.88, CH 4 24.52, CO7.25, CO 2 2.0,N 2 4.29,O 2 0.06,H 2 S100mg / Nm 3 ,Ammonia 270mg / Nm 3 , tar 10mg / Nm 3 , Naphthalene 150mg / Nm 3 ,organic sulfur 200mg / Nm 3 , Benzene 3150mg / Nm 3 . After being compressed to 1.05MPa by the coke oven gas compressor, it enters the temperature swing adsorption pretreatment process (TSA). When the operating temperature is 40°C, the pretreatment tower adsorbs and removes naphthalene, tar and part of NH 3 、H 2 Impurities such as S and benzene are desorbed after the pretreatment tower is heated to 180°C by the heater, and the desorbed and desorbed gas is sent back to the coke oven heating pipe network for comprehensive utilization. Impurity H still exists in coke oven gas after pretreatment and purification 2 S80mg / Nm 3 , ammonia 162mg / Nm 3 ,organic sulfur 120mg / Nm 3 , Benzene 2520mg / Nm 3 , at a temperature of 300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com