Silicone rubber having high resistance to electric erosion and used for insulator, and preparation method thereof

A technology for electrical erosion and insulators, which is applied in the field of high electrical corrosion resistance silicone rubber for insulators and its preparation, can solve the problem of electrical erosion of silicone rubber on the surface of insulators, which cannot have both flame retardancy, tracking resistance and resistance Electrocorrosion and other problems to achieve the effect of improving service life and operating safety, ensuring long-term normal operation, and high flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

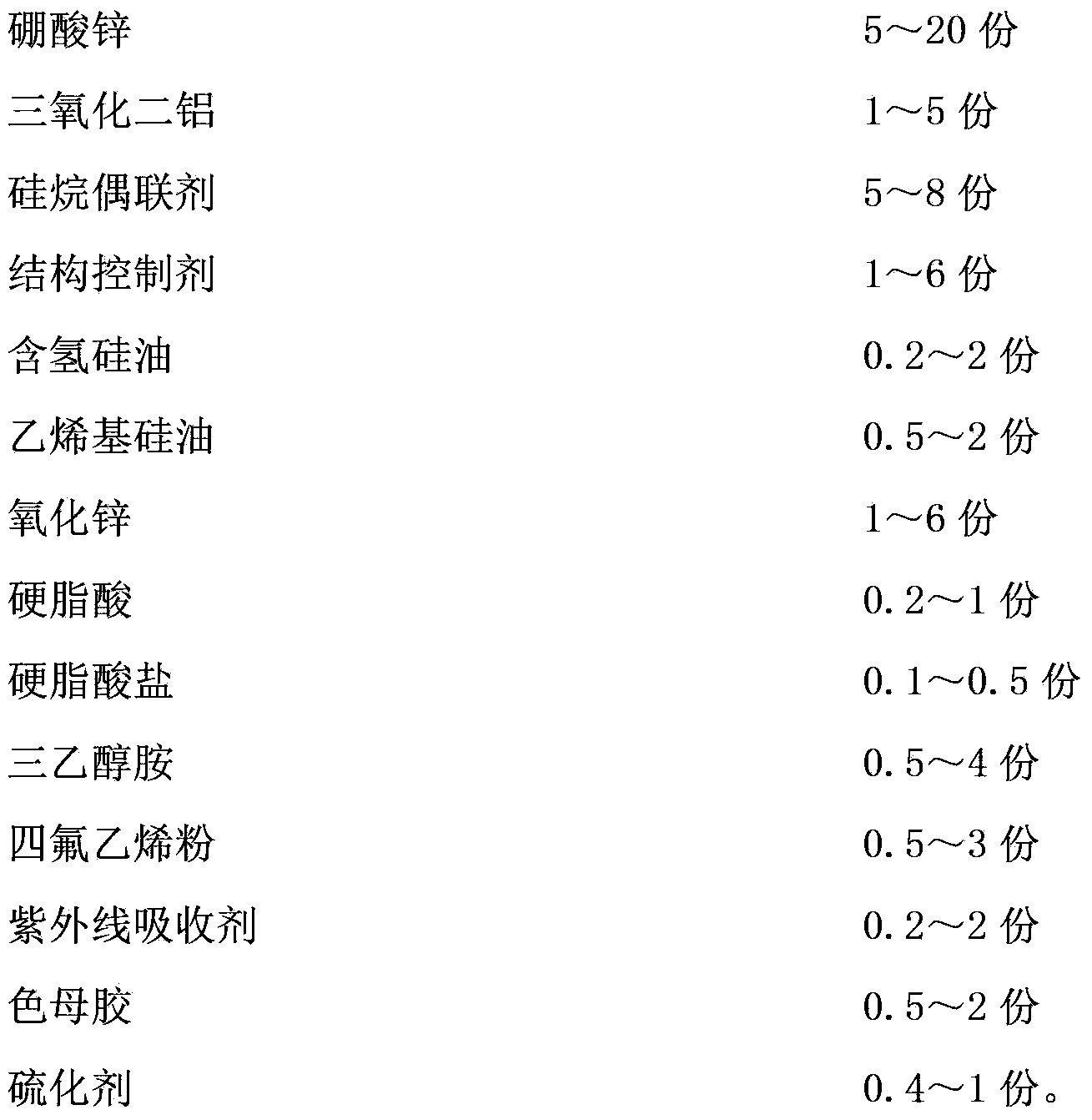

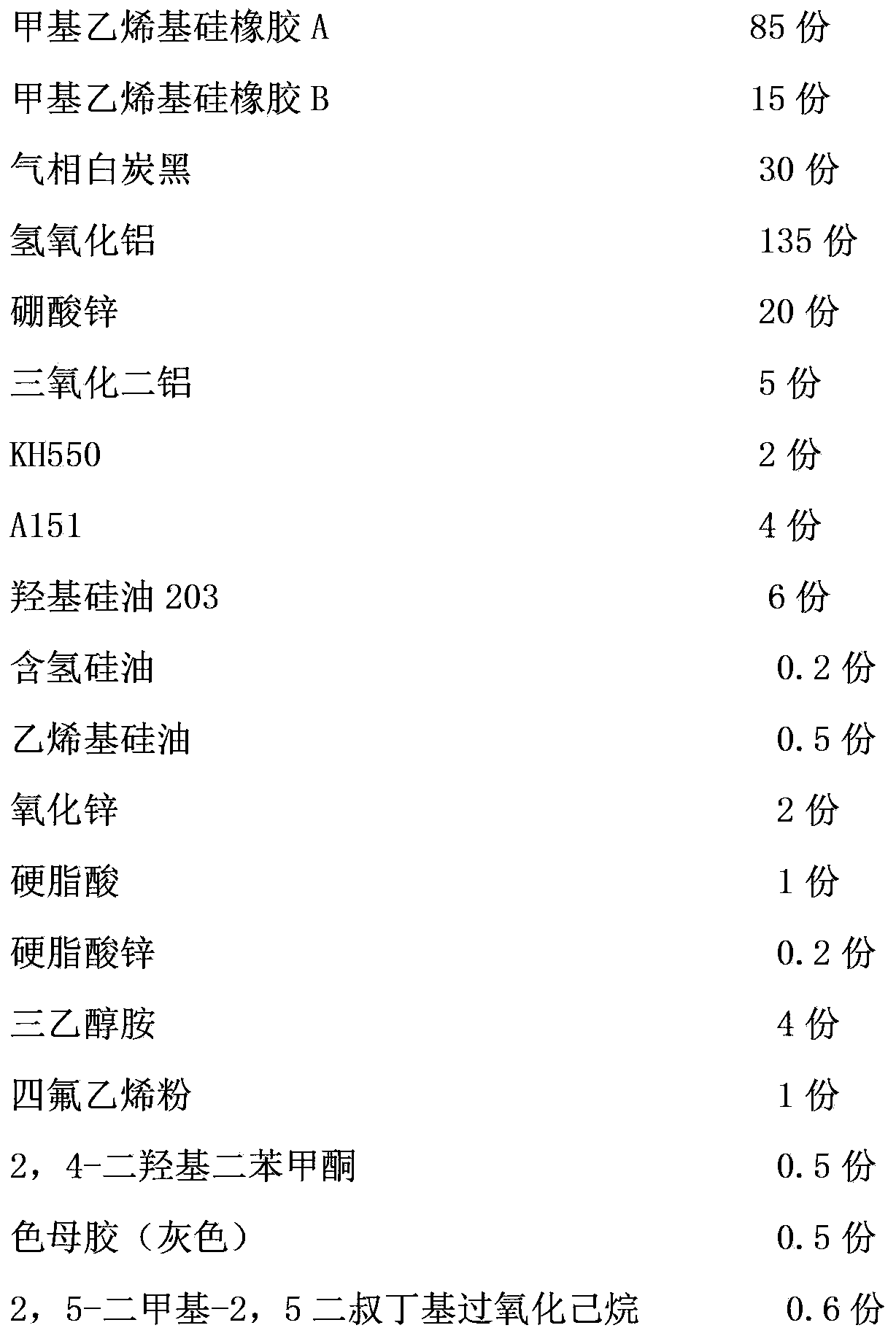

[0028] The insulator of this embodiment is made of high electrical corrosion resistance silicone rubber, which is composed of the following raw materials in parts by weight:

[0029]

[0030] Among them: the molecular weight of methyl vinyl silicone rubber A is 550,000, and the molar fraction of vinyl is 0.10%; the molecular weight of methyl vinyl silicone rubber B is 650,000, and the molar fraction of vinyl is 1.00%; terminal, the branched chain contains vinyl, and the vinyl mole fraction is 6%.

[0031] Among the raw materials of the insulators of this embodiment with high electrical corrosion resistance silicone rubber, the specific surface area of fumed silica is 150m 2 / g; the particle size of aluminum hydroxide is D50 1 μm; the particle size of zinc borate is D50 ≤ 10 μm; the particle size of aluminum oxide is D50 ≤ 10 μm; the particle size of zinc oxide is D50 ≤ 10 μm, and the purity is ≥ 99%; The particle size of tetrafluoroethylene powder is D50≤10μm; the hydrog...

Embodiment 2

[0039] The insulator of this embodiment is made of high electrical corrosion resistance silicone rubber, which is composed of the following raw materials in parts by weight:

[0040]

[0041]

[0042] Among them: the molecular weight of methyl vinyl silicone rubber A is 600,000, and the molar fraction of vinyl is 0.06%; the molecular weight of methyl vinyl silicone rubber B is 700,000, and the molar fraction of vinyl is 0.95%; terminal, the branched chain contains vinyl, and the vinyl mole fraction is 9%.

[0043] Among the raw materials of the insulators of this embodiment with high electrical corrosion resistance silicone rubber, the specific surface area of fumed silica is 300m 2 / g; the particle size of aluminum hydroxide is D50 1 μm; the particle size of zinc borate is D50 ≤ 10 μm; the particle size of aluminum oxide is D50 ≤ 10 μm; the particle size of zinc oxide is D50 ≤ 10 μm, and the purity is ≥ 99%; The particle size of tetrafluoroethylene powder is D50≤10μm; ...

Embodiment 3

[0051] The insulator of this embodiment is made of high electrical corrosion resistance silicone rubber, which is composed of the following raw materials in parts by weight:

[0052]

[0053] Among them: the molecular weight of methyl vinyl silicone rubber A is 650,000, and the molar fraction of vinyl is 0.15%; the molecular weight of methyl vinyl silicone rubber B is 600,000, and the molar fraction of vinyl is 0.90%; terminal, the branched chain contains vinyl, and the vinyl mole fraction is 12%.

[0054] Among the raw materials of the insulators of this embodiment with high electrical corrosion resistance silicone rubber, the specific surface area of fumed silica is 200m 2 / g; the particle size of aluminum hydroxide is D50 1 μm; the particle size of zinc borate is D50 ≤ 10 μm; the particle size of aluminum oxide is D50 ≤ 10 μm; the particle size of zinc oxide is D50 ≤ 10 μm, and the purity is ≥ 99%; The particle size of tetrafluoroethylene powder is D50≤10μm; the hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com