A kind of ultra-long weather-resistant baking varnish and preparation method thereof

A baking paint and weather-resistant technology, which is applied in the coating and other directions, can solve the problems of affecting the service life of metal substrates, polluting the surrounding environment, and uneven mixing, so as to improve mixing efficiency and uniformity, strong carbon-fluorine bond energy, and mechanical strength. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An ultra-long weather-resistant baking varnish, its raw material composition is calculated by mass fraction: fluorocarbon resin 45%, amino resin 15%, aluminum powder 10%, polyurethane 1%, butyl ester 15%, ultra-fine tea stem powder 10%, silane Coupling agent 4%.

[0035] A method for preparing the above-mentioned ultra-long weather-resistant baking varnish, the specific steps are:

[0036] 1) The tea stems are dried at 90°C until the water content is 1%-3%, crushed, and passed through a 300-mesh sieve to obtain tea stem powder; mix the tea stem powder with the coupling agent, and stir for 10 minutes;

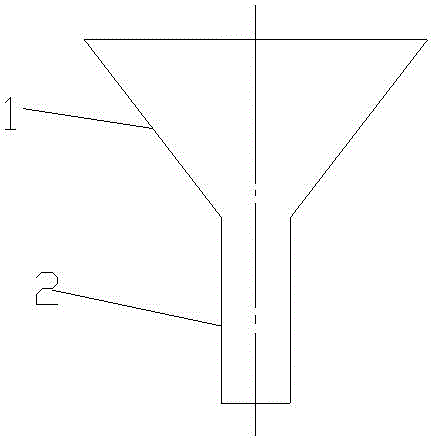

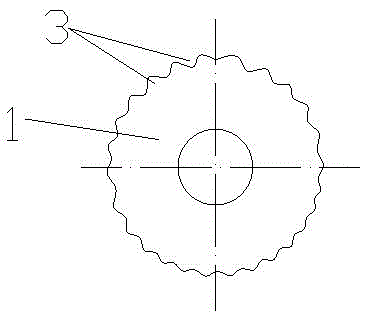

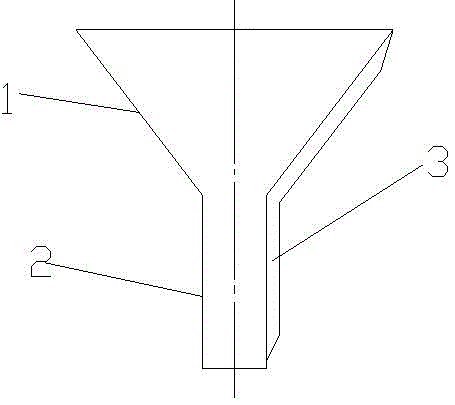

[0037] 2) Add fluorocarbon resin, pigments and fillers into the reaction kettle through the paint raw material step feeding stirring mixing device, the paint raw material step feeding stirring mixing device includes a ladder with four steps and a step at the bottom A reaction kettle at the side, a stirring shaft is inserted into the reaction kettle, an upper stirring kni...

Embodiment 2

[0042]An ultra-long weather-resistant baking varnish, its raw material composition is calculated by mass fraction: fluorocarbon resin 45%, amino resin 15%, titanium dioxide 25%, polyacrylate 2%, ultra-fine tea stem powder 5%, titanate bismuth Joint agent 2%, cyclohexanone 6%.

[0043] A method for preparing the above-mentioned ultra-long weather-resistant baking varnish, the specific steps are:

[0044] 1) The tea stems are dried at 110°C until the water content is 1%-3%, crushed, and passed through a 400-mesh sieve to obtain tea stem powder; mix the tea stem powder with a coupling agent, and stir for 20 minutes;

[0045] 2) Add fluorocarbon resin, pigments and fillers into the reaction kettle through the paint raw material step feeding stirring mixing device, the paint raw material step feeding stirring mixing device includes a ladder with four steps and a step at the bottom A reaction kettle at the side, a stirring shaft is inserted into the reaction kettle, an upper stirri...

Embodiment 3

[0050] An ultra-long weather-resistant baking varnish, its raw material composition is calculated by mass fraction: fluorocarbon resin 37%, amino resin 13%, iron oxide red 22%, organic silicon 1%, ethylene glycol butyl ether 10%, ultra-fine tea stem Powder 10%, aluminate coupling agent 2%, ethylene glycol butyl ether 5%.

[0051] A method for preparing the above-mentioned ultra-long weather-resistant baking varnish, comprising the following steps:

[0052] 1) The tea stems are dried at 120°C until the water content is 1%-3%, crushed, and passed through a 500-mesh sieve to obtain tea stem powder; mix the tea stem powder with a coupling agent, and stir for 30 minutes;

[0053] 2) Add fluorocarbon resin, pigments and fillers into the reaction kettle through the paint raw material step feeding stirring mixing device, the paint raw material step feeding stirring mixing device includes a ladder with four steps and a step at the bottom A reaction kettle at the side, a stirring shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com