Hydrometallurgical method for refining tungsten from tungsten oxide limonite

A technology of hydrometallurgy and limonite, which is applied in the direction of improving process efficiency, can solve the problems of high energy consumption, high cost, and inability to realize comprehensive utilization of valuable resources, and achieve clear solution, easy filtration, and improved comprehensive utilization efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

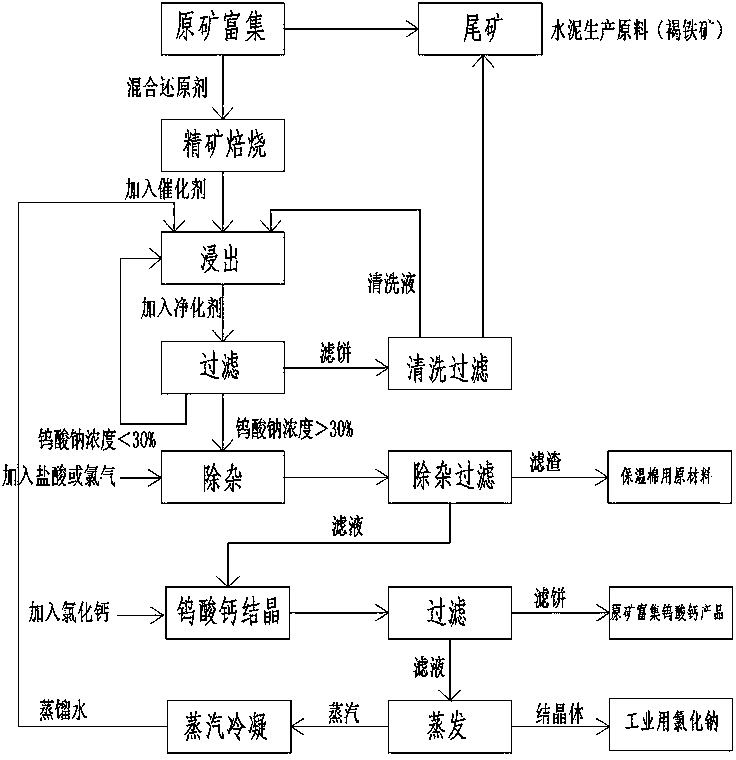

Image

Examples

Embodiment 1

[0036]The process method is used to process tungsten-containing limonite containing 31% iron and 0.3% tungsten. Firstly, the limonite is processed by a sand blasting machine, and then the particles are sent to the jigging beneficiation according to the solid-to-liquid ratio of 1:10 and river water (can process 40-60T raw ore per hour, power consumption 22KWH), and select coarse-grained concentrate, Medium ore and tailings; combine coarse-grained concentrate and medium ore to obtain enriched concentrate containing 1.5% tungsten oxide, and the tailings are sent as raw materials for cement building materials; the enriched tungsten concentrate is divided into tungsten concentrate: sodium carbonate: Calcium oxide: anthracite = 20:0.8:0.3:1 mass ratio mixed; roasted at 750°C for 10 minutes, the roasted sintered body is air-cooled and heat-exchanged, cooled, and then enters the mill to obtain a particle size of 120 mesh The above reduced roasting powder; the leaching mother liquor is...

Embodiment 2

[0038] The process method is used to process tungsten-containing limonite containing 26% iron and 0.6% tungsten. First, the limonite is processed by a sand blasting machine, and then the particles are sent to the jig beneficiation according to the solid-to-liquid ratio of 1:10 and mountain spring water (can process 40-60T raw ore per hour, and the power consumption is 22KWH), and the coarse-grained concentrate, Medium ore and tailings; combine coarse-grained concentrate and medium ore to obtain enriched concentrate containing 2% tungsten oxide, and the tailings are sent as raw materials for cement building materials; the enriched tungsten concentrate is divided into tungsten concentrate: sodium carbonate: Calcium oxide: anthracite = 20:0.8:0.3:1 mass ratio mixed; roasted at 750 ° C for 12 minutes, the roasted sintered body is air-cooled and heat-exchanged, cooled, and then enters the mill to obtain a particle size of 120 mesh The above reduced roasting powder; the leaching mot...

Embodiment 3

[0040] The process method is used to process tungsten-containing limonite containing 30% iron and 0.5% tungsten. Firstly, the limonite is processed by a sand blasting machine, and then the particles are sent to the jigging beneficiation according to the solid-to-liquid ratio of 1:10 and river water (can process 40-60T raw ore per hour, power consumption 22KWH), and select coarse-grained concentrate, Medium ore and tailings; combine coarse-grained concentrate and medium ore to obtain enriched concentrate containing 1.6% tungsten oxide, and the tailings are sent as raw materials for cement building materials; the enriched tungsten concentrate is divided into tungsten concentrate: sodium carbonate: Calcium oxide: anthracite = 20:0.8:0.3:1 mass ratio mixed; roasted at 800°C for 15 minutes, the roasted sintered body is air-cooled and heat-exchanged, cooled, and then enters the pulverizer to obtain a particle size of 120 mesh The above reduced roasting powder; the leaching mother li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com