Zero emission type chemical nickel plating liquid

An electroless nickel plating solution and discharge type technology, applied in liquid electroless plating, metal material coating process, coating and other directions, can solve the problem of no low-cost treatment method, etc., and achieve considerable economic benefits, fast deposition rate, and durability. good corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

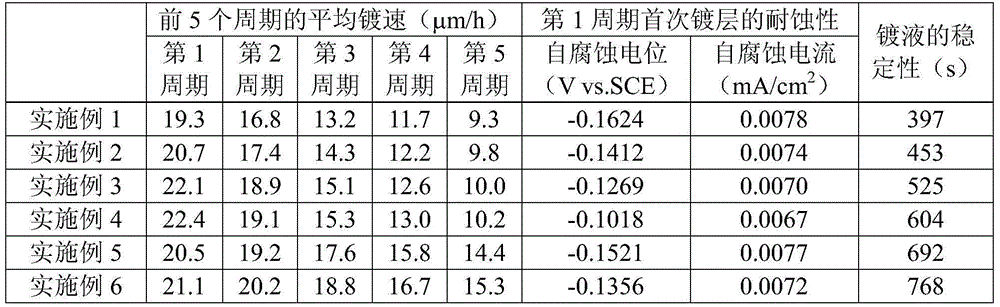

Embodiment 1

[0020] Embodiment 1: this electroless nickel plating liquid, comprises the component of following content: nickel hypophosphite 0.1mol / L, hypophosphorous acid 0.05mol / L, citric acid 6g / L, acetic acid 15g / L, maleic acid 1.5g / L, copper acetate 1g / L, and the rest is deionized water. After the electroless nickel plating solution is prepared according to the above-mentioned components and contents, it is used for the electroless nickel plating of the pretreated carbon steel test piece. The electroless nickel plating process is as follows: the temperature of the plating solution is controlled at 85°C, the pH value of the plating solution is 4.8, and the plating is performed for 30 minutes. After the electroless nickel plating is completed, test the coating plating speed and corrosion resistance, the stability and life of the plating solution, and record the test results in Table 1.

Embodiment 2

[0021] Embodiment 2: this electroless nickel plating liquid, comprises the component of following content: nickel hypophosphite 0.15mol / L, hypophosphorous acid 0.05mol / L, citric acid 10g / L, acetic acid 20g / L, maleic acid 1.5g / L, copper acetate 1g / L, glutaric acid 1g / L, and the rest is deionized water. After the electroless nickel plating solution is prepared according to the above-mentioned components and contents, it is used for the electroless nickel plating of the pretreated carbon steel test piece. The electroless nickel plating process is as follows: the temperature of the plating solution is controlled at 85°C, the pH value of the plating solution is 4.8, and the plating is performed for 30 minutes. After the electroless nickel plating is completed, test the coating plating speed and corrosion resistance, the stability and life of the plating solution, and record the test results in Table 1.

Embodiment 3

[0022] Embodiment 3: this electroless nickel plating liquid, comprises the component of following content: nickel hypophosphite 0.2mol / L, hypophosphorous acid 0.05mol / L, citric acid 20g / L, acetic acid 20g / L, maleic acid 2g / L L, copper acetate 3g / L, glutaric acid 2g / L, and the rest are deionized water. After the electroless nickel plating solution is prepared according to the above-mentioned components and contents, it is used for the electroless nickel plating of the pretreated carbon steel test piece. The electroless nickel plating process is as follows: the temperature of the plating solution is controlled at 85°C, the pH value of the plating solution is 4.8, and the plating is performed for 30 minutes. After the electroless nickel plating is completed, test the coating plating speed and corrosion resistance, the stability and life of the plating solution, and record the test results in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com