A fluidized bed semi-coke heat carrier system and method for preventing boiler fouling

A carrier system and fluidized bed technology, which is applied in the field of fluidized bed, can solve the problems of power plant boiler contamination, etc., and achieve the effects of stabilizing boiler output, improving efficiency, and improving energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

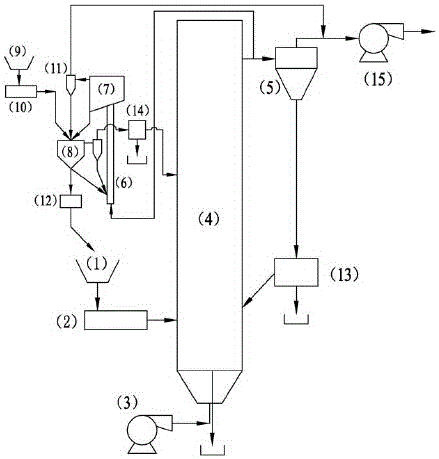

[0025] like figure 1 As shown, a fluidized bed semi-coke heat carrier system for preventing boiler fouling includes a fluidized bed 4, a heating riser 6, a hot semi-coke tank 7, a pyrolysis reactor 8, a separator 11, and a fluidized bed The flue gas outlet of 4 is respectively connected to the heating riser 6 and the tail flue device, the outlet of the heating riser 6 is connected to the hot semi-coke tank 7; the high-temperature semi-coke outlet of the hot semi-coke tank 7 is connected to the pyrolysis reactor 8, The coal ash outlet of the pyrolysis reactor 8 is connected to the feed end of the fluidized bed 4 and the heating riser 6 respectively;

[0026] The flue gas outlet of the hot semi-coke tank 7 is connected to the separator 2 11, the coal ash outlet of the separator 2 11 is connected to the pyrolysis reactor 8, and the flue gas outlet of the separator 2 11 is connected to the tail flue device;

[0027] The flue gas outlet of pyrolysis reactor 8 is connected to fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com