Silica sol dispersed in organic solvent, and method of manufacturing said silica sol dispersed in organic solvent

A technology of silica and organic solvents, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve problems such as easy increase in viscosity, difficulty in dispersing, and difficulty in obtaining sols, and achieve inhibition of aggregation, inhibition of aggregation, and stable dispersion excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

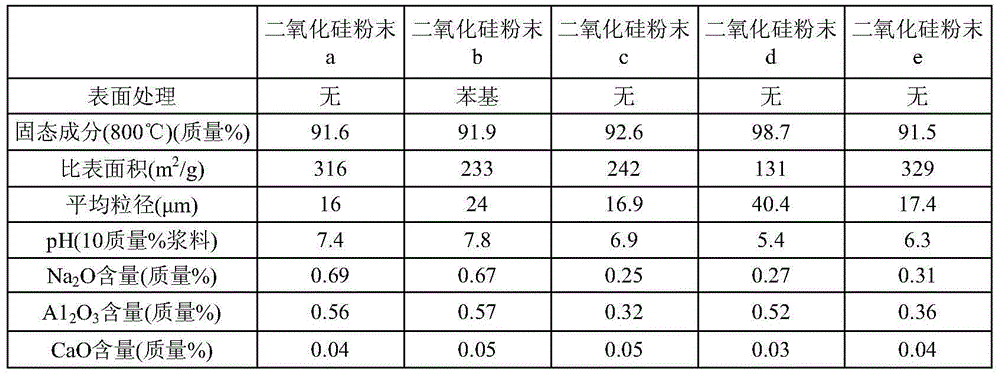

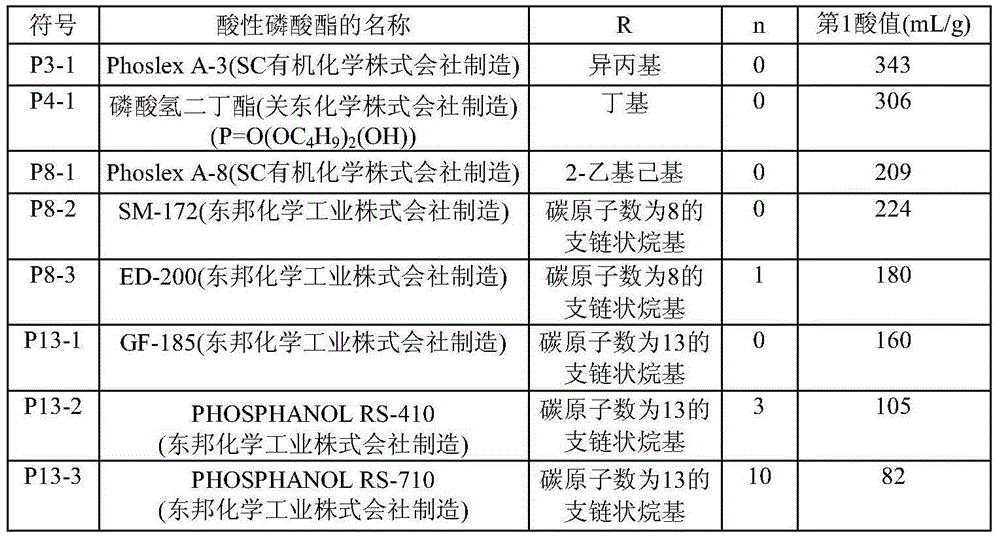

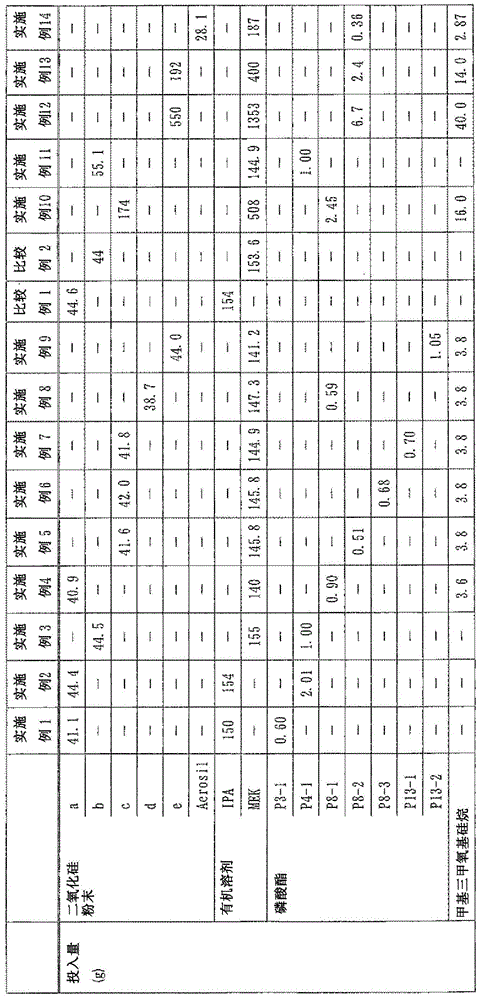

[0051] Into a plastic container with a capacity of 500 ml and a diameter of 70 mm, 41.1 g of silica powder a obtained by sedimentation method described in Table 1 as raw material silica particles, and 2-propanol (hereinafter also referred to as IPA) 150g, acid phosphate P3-10.60g recorded in Table 2 as the acid phosphate, 180g of soda lime glass beads with a diameter of 1 mm to 1.5 mm as the grinding medium, and after grinding at a rotation speed of 130 rpm for 72 hours, filter the beads , to obtain IPA-dispersed silica sol (organic solvent-dispersed silica sol). The physical properties of the silica powder used are shown in Table 1, the acid phosphate ester used is shown in Table 2, and the compounding ratio of the silica sol is shown in Table 3.

[0052] In addition, in Table 1, the silica powder was calcined at 800 degreeC for 30 minutes, and the solid content was calculated|required. In addition, the specific surface area was determined by the Sears titration method descr...

Embodiment 2~9

[0060] The types and mixing ratios of silica powder, the types and mixing ratios of acidic phosphate esters, and the types and mixing ratios of organic solvents are shown in Table 3, except that the same operations as in Example 1 were carried out. , to obtain an organic solvent-dispersed silica sol, and implement a measurement of physical properties and a heating acceleration test. In addition, regarding Examples 4-9, methyltrimethoxysilane was added in the compounding ratio shown in Table 3 before a pulverization process. In addition, in the examples and comparative examples described later, when using methyl ethyl ketone (hereinafter also referred to as MEK) instead of IPA as the organic solvent, the pH meter was used to measure and add the same mass of MEK dispersed silica sol. Table 4 shows the pH of the solution of water and methanol of the same mass.

Embodiment 10

[0064] A bead mill with a slurry tank (Apex Mill 015 crushing chamber capacity 150 ml manufactured by Kotobuki Kogyo Co., Ltd.) was filled with 100 ml of soda lime glass beads (Soda Laim Beads) with a diameter of 0.2 mm, and 508 g of methyl ethyl ketone was added. , 87 g of silica powder c was added over 2 minutes while the pulverizer (bead mill) was circulated at a peripheral speed of 6 m / s. Next, add 8-12.45 g of acid phosphate ester, then add 87 g of silica powder c over 4 minutes, then add 16.0 g of methyltrimethoxysilane, increase the peripheral speed to 8 m / s, and perform pulverization for 180 minutes , to obtain MEK dispersed silica sol (organic solvent dispersed silica sol). The physical properties of the silica powder used are shown in Table 1, the acid phosphate ester used is shown in Table 2, and the compounding ratio of the silica sol is shown in Table 3.

[0065] The obtained MEK-dispersed silica sol had a solid content of 24.2% by mass, a water content of 1.5% b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Dispersed particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com