A kind of repairable veneer veneer adhesive and its synthesis method

A technology for adhesives and veneers, which is applied in the direction of adhesives, monocarboxylate copolymer adhesives, polymer adhesive additives, etc., can solve the problems of aesthetics and practicability that cannot meet people's requirements, and achieve a solution that can be achieved Repairing problems, improving wet adhesion performance, and solving the effect of formaldehyde release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

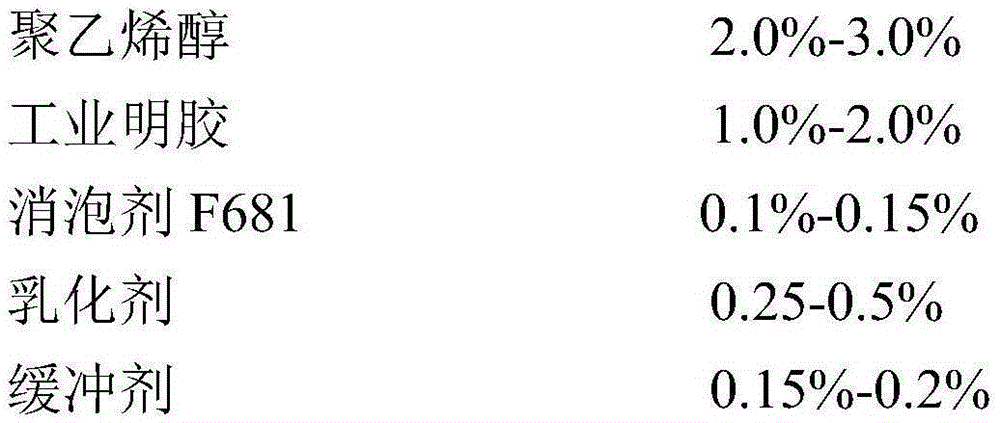

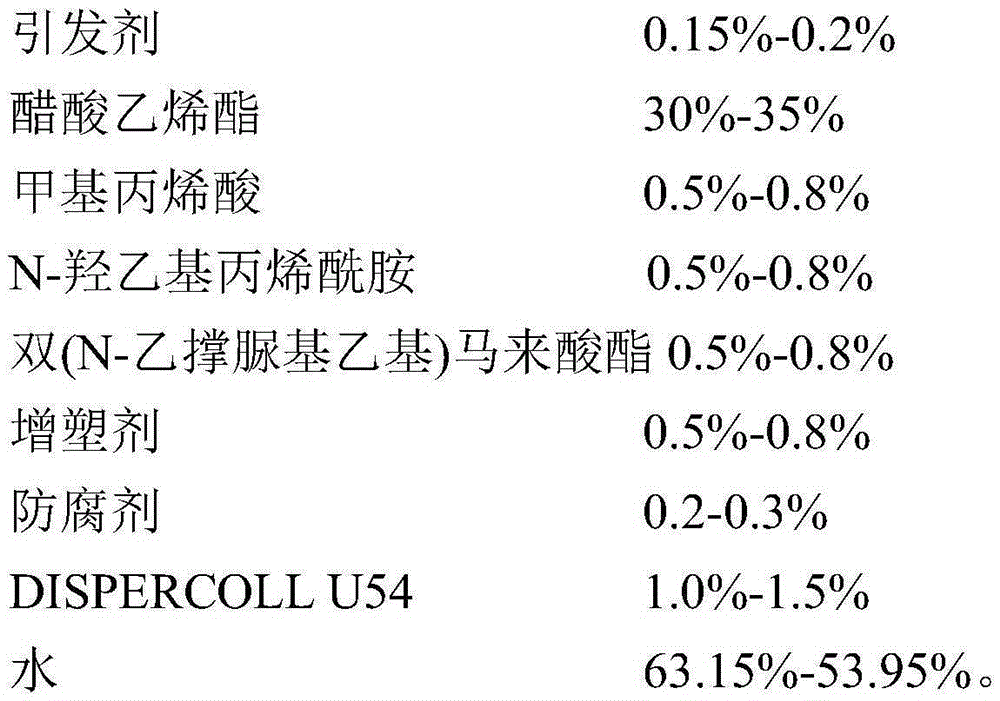

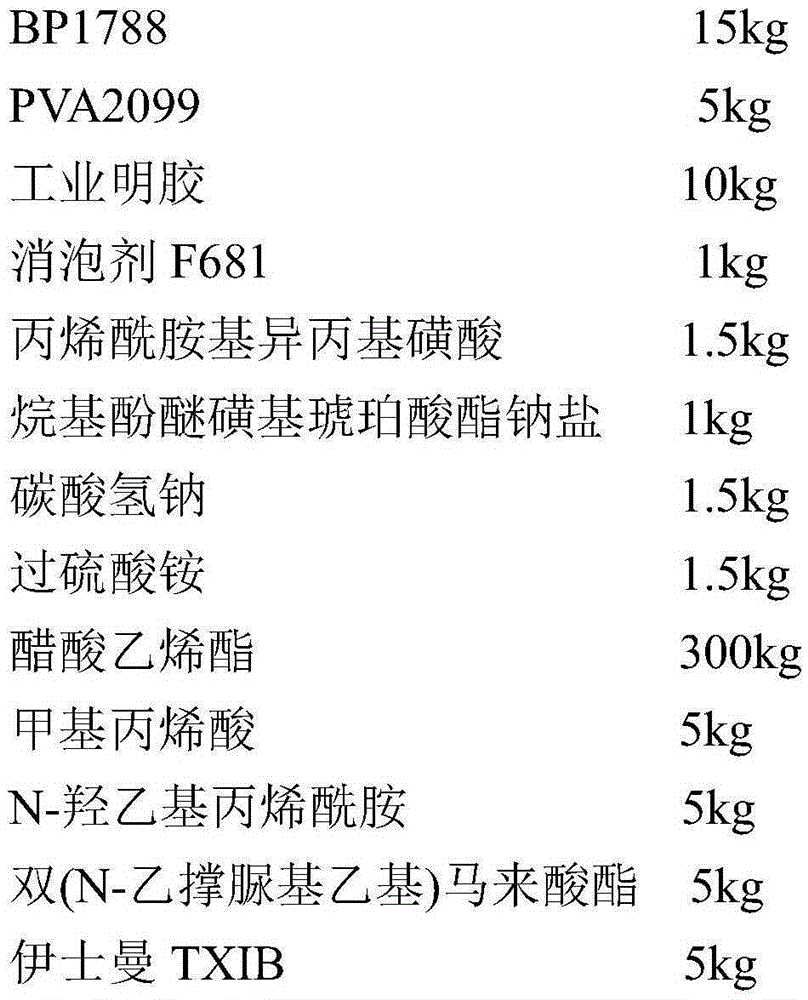

[0028] Formula: total amount = 1000kg

[0029]

[0030]

[0031] Production Process:

[0032] 1. Dissolve 1.5kg ammonium persulfate in 28.5kg water to obtain a 5% initiator aqueous solution with a mass fraction;

[0033] 2. Mix and stir 5kg of methacrylic acid, 5kg of N-hydroxyethylacrylamide, 5kg of bis(N-ethyleneureidoethyl) maleate and 268.5kg of vinyl acetate to make a mixed monomer co- 283.5kg;

[0034] 3. After the equipment is checked to be normal, put in 603kg of tap water, start the reactor with a condenser, add 15kg of polyvinyl alcohol PVABP1788, 5kg of PVA2099 and 10kg of industrial gelatin, raise the temperature to 85°C and keep it warm for 50 minutes to fully dissolve the polyvinyl alcohol and industrial gelatin;

[0035] 4. Cool down to 50°C and add 1.5kg of acrylamido isopropylsulfonic acid, 1kg of sodium alkylphenol ether sulfosuccinate, 1.5kg of sodium bicarbonate and 1.0kg of defoamer F681.0kg and stir evenly, then quickly add vinyl acetate Ester 31...

Embodiment 1

[0037] The product technical index that embodiment 1 obtains is detected according to the HG / T2727-2010 standard:

[0038] Appearance: milky white viscous liquid

[0039] PH value: 4-5

[0040] Viscosity: 28000~32000CPS, Brookfieldsp.4, 12rpm., 25℃

[0041] Solid content: 36.2±1%

[0042] Minimum film forming temperature: 5°C, glass transition temperature: about 20°C

[0043] Dry state compressive shear strength: 10.2MPa

[0044] Free formaldehyde: no

Embodiment 2

[0046] Formula: total amount = 1000kg

[0047]

[0048]

[0049] Production Process:

[0050] 1. Dissolve 1.8kg of ammonium persulfate in 34.2kg of water to obtain a 5% aqueous initiator solution;

[0051] 2. Mix and stir 6kg of methacrylic acid, 6kg of N-hydroxyethylacrylamide, 6kg of bis(N-ethyleneureidoethyl) maleate and 294.6kg of vinyl acetate to make a mixed monomer co- 312.6kg;

[0052] 3. After the equipment is checked to be normal, put in 548.5kg of tap water, start the reactor with condenser, add polyvinyl alcohol 12kgBP2488, 5kgBP0588, 8kgPVA1799 and 15kg of industrial gelatin, heat up to 88°C and keep warm for 55 minutes to make polyvinyl alcohol and industrial gelatin fully dissolved;

[0053]4. Cool down to 55°C and add 1.6kg of sulfosuccinate derivatives, 1.3kg of alkylphenol ether sulfosuccinate sodium salt, 1.8kg of sodium dihydrogen phosphate and 1.3kg of defoamer F681 and stir evenly, then quickly add acetic acid Vinyl ester 35.4kg and initiator aq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com